Digital Destination: Arrived

After 15 years in the stone industry, Mike Phelix was ready to branch out on his own. In 2015, he began Granite Details – starting with just him and one other person. Leading the list of future goals for his new granite shop in North Carolina, was to fabricate digitally. Over the next few years, he made a journey -one many in the industry can relate to: Rail Saw. Bridge Saw. CNC Saw.

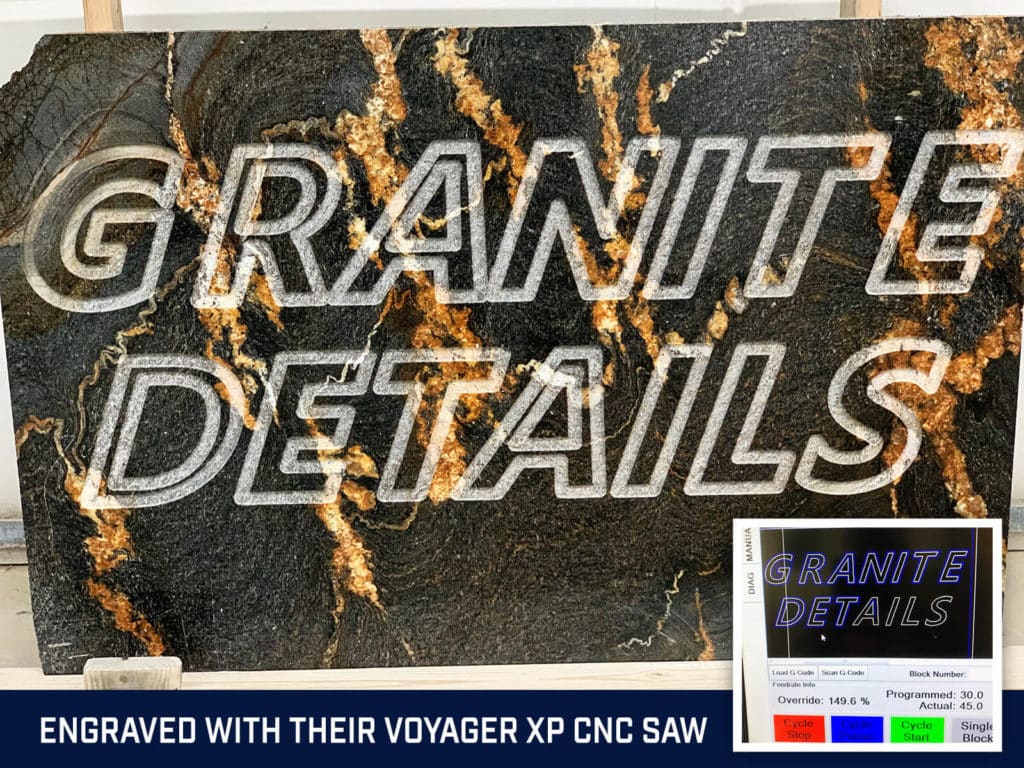

In the fall of 2019, a VOYAGER™ XP 5-Axis CNC Saw and Pathfinder® Digital Imaging Station were installed at Granite Details. Mike had arrived at his desired digital destination.

Country & Company

After researching which CNC saw to handle his cutting, Mike decided to partner with Park Industries® for two key reasons:

#1: Their reputation for service and after sales support was immense. Mike explains, “Going from stick templates to CNC was daunting for me. I needed a company with a great support system to feel comfortable making that transition.”

His experience? “There was a lot for us to learn, but every question we had, their support was spot-on. The installation process went so smoothly, I don’t know how it could be better unless they stayed and worked for us (laughs). I’ve been in the industry for 20+ years now and their service is untouchable…no one else matches up to it. They 100% have our back.

#2: Park Industries® machinery is made in St. Cloud, Minnesota, USA. Mike shares his pride in buying American, “That wins it for me all day long. I’d spend double the money (though the price was competitive) to go with an American Made machine.”

A Lot to Like

“Man, I love it.” Mike says about the VOYAGER™ XP, “The speed, accuracy, and reliability of it are night and day better from when we cut manual. It also elevates our company’s professionalism.” The VOYAGER XP brings a lot to the table as far as features go. Mike’s thoughts on some of the key ones:

TightCut Blade Plunging: “We use it on every single job. It works awesome and saves us plenty of milling time on sinks.”

27 hp Motor: “We’ve cut quartzites, Dektons and other hard materials with no issues. The motor doesn’t budge and handles them extremely well.”

Ultra-Compact Automation: “It makes programming these complex materials dummy-proof, handling aspects like ramping the saw up and down automatically for entering/exiting cuts.”

Mitering: “We did a mitered fireplace with Patagonia, a delicate material that chips easily. It would’ve been catastrophic on our bridge saw, but the miters went through like butter on the VOYAGER™ XP.”

“This house is on the top of a mountain – they chose a very fitting color.” Granite Details • VOYAGER XP • Patagonia 🔥

Posted by Park Industries on Wednesday, August 5, 2020

A Boost to Polishing Production

In the Fall of 2020, with his VOYAGER™ XP in full swing, Mike looked to Park Industries once again for a boost – this time to his polishing production. He added a FASTBACK® II Edge Polisher with SlabBACK™ support system.

The FASTBACK® II was the cherry on top for Mike’s shop: “It’s literally like what the guy in Park’s video says – you put stone in one end and take money out the other. I mean it does the work of 3-4 polishers. I can’t feed the FASTBACK® II fast enough, and the finish comes off like glass – a perfect polish.”

He continues, “We run full islands through it and use every bit of the 96 inches the SlabBACK™ gives us. The polish still turns out perfect. I wish I got this machine years ago – it’ll pay for itself in a year or so.”

Results: More than Numbers

Since adding the VOYAGER™ XP and FASTBACK® II, Granite Details has doubled their production “by far” and are “just scratching the surface” of what they can do. Beyond the impressive new numbers, Mike points out two benefits that can’t really be measured, but are “worth the machine’s weight in gold” to him:

#1: Being able to set a program, hit go and walk away from the machine has been freeing for him.

#2: The VOYAGER™ XP, specifically the router bit, has improved his shop’s safety and cleanliness. Mike explains, “We used to grind out sinks with dust flying around. Now the machine drops them for us automatically and completely dust free. Prior to the saw, I kept a clean environment, but since we’ve had it, I’ve had customers tell me our shop looks like a showroom.”

Granite Details’ shop is now ready to meet the increasing demands of their market, with production capabilities to fabricate any material efficiently. A worthwhile digital journey, indeed.

Different VOYAGER™ XP Projects by Granite Details

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.