Quick Machine Finder

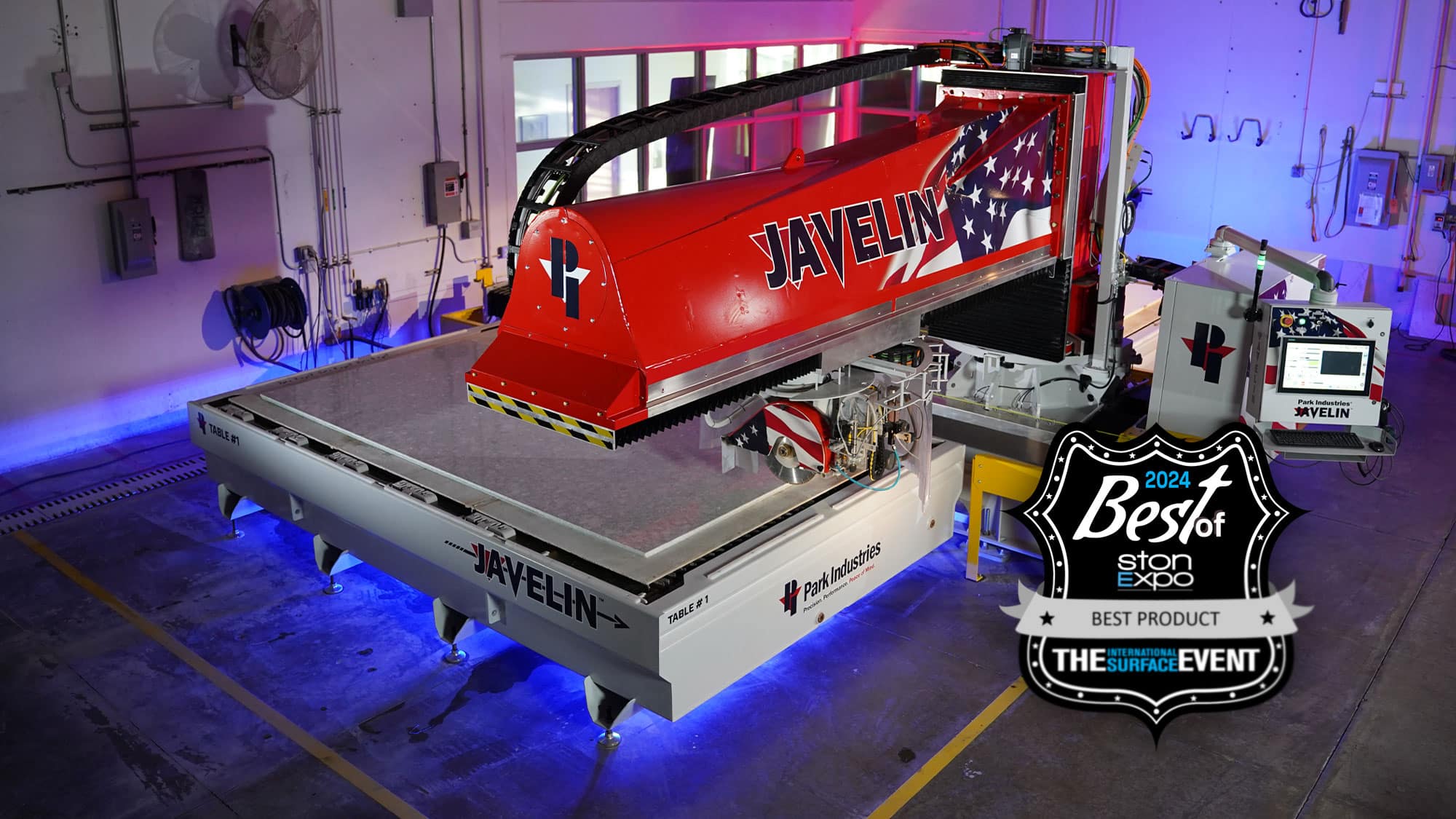

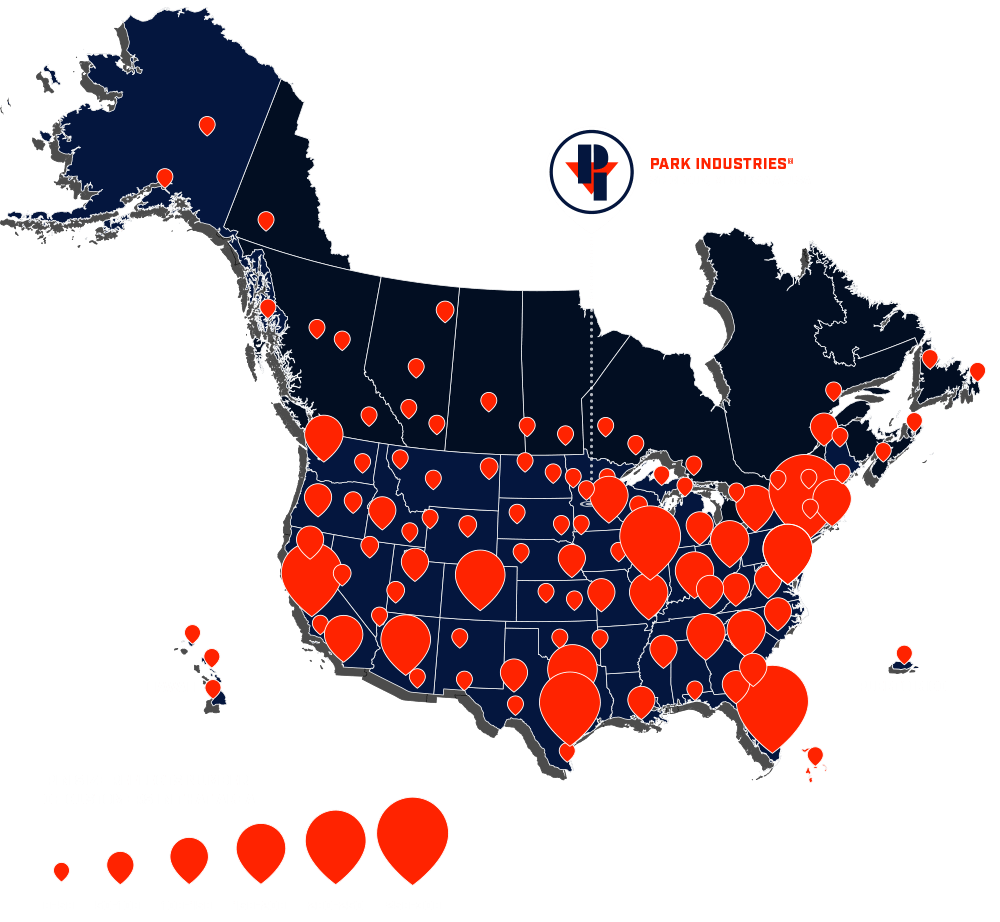

North America’s Leader in Countertop & Architectural Machinery

SERVING OVER 5,000 CUSTOMERS

Sure, Park Industries® sells superior machines for countertop and architectural fabricators, but that’s not really all we do. We’re in the business of providing you the tools that will positively impact your bottom line.

We are also laser focused on creating outstanding experiences by providing the most dependable, high-precision manufacturing solutions that enable our customers, associates, and community to thrive.

Latest Articles

Contact Us

We’d love to hear from you

Your comments and questions are important to us. Please complete the form and we’ll respond to your inquiry promptly, or find your sales representative.

6301 Saukview Dr

St. Cloud, MN 56303

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.