Blake and Jill Wamstad of Hatton Granite (North Dakota) share their story of why they partnered with Park Industries and invested in digital technology which changed their business and lives.

Hatton Granite Co.

Hatton Granite Company opened its doors in 1904. The fifth-generation family business is North Dakota’s oldest producer of granite monuments. Great, great grandson Blake Wamstad, and his wife Jill now currently operate the company’s countertop division.

Similar to the generations before him, Blake is a very hands-on business owner who enjoys programming and operating the machines as well as interacting with customers. He designs, fabricates, and installs custom kitchen countertops and bathroom vanities throughout the area, working with about 70% residential projects and 30% commercial jobs.

Read their story! Expand the sections below to learn more about Hatton Granite’s story and their partnership with Park Industries®.

A Partnership Forms

Hatton Granite and Park Industries® Meet

Hatton Granite hadn’t always fabricated countertops, but when Blake began fielding phone calls for granite countertop projects more regularly, he began considering it. Hatton Granite was invited to a Quarry Days event where they had the opportunity to tour Park Industries’ facility and a monument company that had diversified into the countertop business. This event sparked fresh excitement at Hatton Granite to begin selling and fabricating countertops.

Hatton Granite was drawn to Park Industries® because of how close they were in distance and their business model aligned well with the values of Hatton Granite’s business. In the initial conversations with Park Industries®, Blake considered adding a PRO-EDGE® or WIZARD to the shop to assist with production. After assessing where the industry was headed and the type of equipment his bigger competitors were looking to add, Blake made the decision to purchase a CNC machine.

Investing in the Future

Hatton Granite and Park Industries® built their relationship on trust and Blake had full confidence in the Park Industries® DESTINY CNC. He felt so strongly he sold his house to make the investment with the DESTINY. Blake shares, “I knew the industry was headed in the CNC direction and that there was no better company to partner with than Park Industries®. This decision impacted my life in the best way.”

For the first couple years, Hatton Granite grew slowly. Jill Wamstad joined Hatton Granite in 2008 and was impressed by the efficiency of the DESTINY CNC and YUKON® running in the shop. Jill thought Hatton Granite was set for life with their state-of-the-art equipment. When Park Industries® called she would not pass the messages along to Blake, so that he wouldn’t buy more equipment. In addition to fielding calls, Jill would even turn the lights off to act like the shop was closed if Park stopped by to visit.

Transforming Their Shop

The Digital Experience

In 2009, Blake attended his first Digital Stoneworking Expo™ (DSE). He left the DSE with a Laser Templating system in hand and a plan in mind. After watching the FUSION® & TITAN® in action, Blake knew they were game changers. Jill was skeptical about adding new equipment, but Blake was optimistically persistent. In the next few years Jill and Blake sold the DESTINY and purchased the TITAN® 1600, FUSION®, FASTBACK®, and Pathfinder®.

The digital transformation changed Jill’s mindset. As Hatton Granite’s production grew and they began taking increasing their market share, Jill welcomed phone calls from Park Industries® with an entirely new appreciation for the stoneworking equipment manufacturer. Blake shares, “Going digital transformed our shop. After making the transition, that is when things really got fun. Fabrication got so much easier!”

Transforming Their Shop

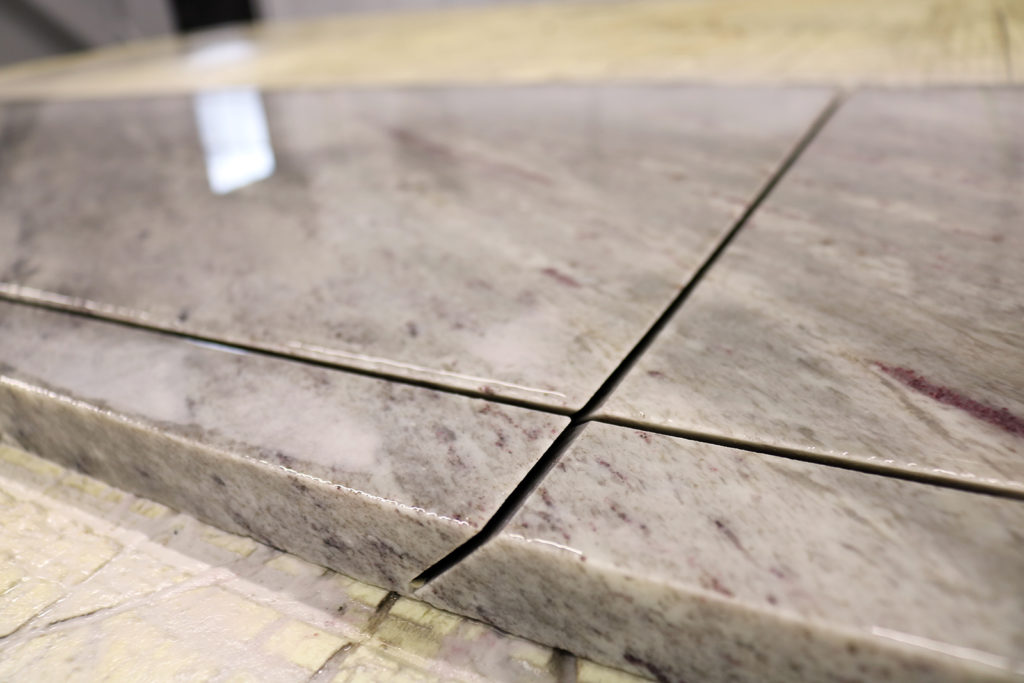

1. FUSION® Production: Blake is passionate that the FUSION® CNC SawJet is one of the best money-making machines he has owned. The FUSION® has boosted production capabilities for Hatton Granite. – “We have four fabricators including me. If we continued to work like we did before the FUSION® CNC SawJet, we would need at least 20 people to do the same amount of work,” Blake says. “This machine increased the number of jobs we can do by 500 percent without increasing my labor costs.” – The FUSION® CNC saw is three times faster than conventional bridge saws. Hatton runs the FUSION® at least four days a week, cutting an average of 1,000 feet of stone in that time.

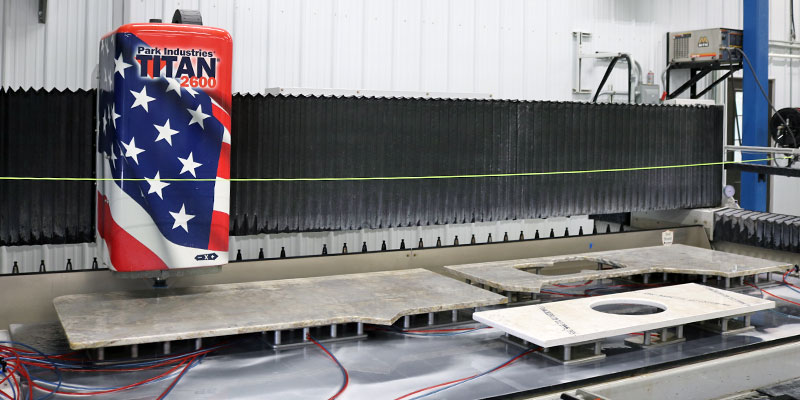

2. TITAN® Efficiency: The changes in efficiency that the TITAN® CNC Router has brought to Hatton Granite is unbeatable. – Blake elaborates, “The tool setup by hand on the DESTINY takes 4-6 hours. With the Integrated Tool Management system on the TITAN®, it takes 20 minutes.” Blake used to have to set aside time on his weekends to set up the tools so that the DESTINY could run during the week. – Blake says, “The TITAN® is 3-4 times more efficient overall. We can set it up at the end of the day, press “Go”, and get it in the morning. We get an extra 200 square footage with the machine’s ability to work on its own.” – The TITAN® can run for three hours with no one manning it. – Hatton Granite’s payback on the TITAN® was less than 1 year based upon the additional capabilities and features compared to their previous machine.

3. Software Solution: The digital imaging capabilities of the Pathfinder® and its advanced software matches each piece of granite to a particular job. – Going digital has eased the backbreaking work for Blake’s team. – Countertops and vanities come off the table ready for install. – The OPS maintenance has been helpful because as Blake says, “Our focus is cutting stone and getting product out the door, not babysitting the machine.” The reminder the machine gives when it’s time to grease the rails or perform any other maintenance activity is appreciated.

Always Evolving

Continuous Growth

Blake explains how they have consistently traded-in and traded-up as they have purchased new machinery, “Our Park machinery over the years has paid for themselves. Our strategy is to sell old equipment and buy new equipment to make money.”

1.TITAN® Upgrade: Hatton Granite swapped out their TITAN® 1600 for the TITAN® 2600. The speed of the upgraded TITAN® has brought great value to Hatton Granite.

2.The Perfect Fit: The recent addition of the SABER™ 5-Axis CNC Saw has replaced the YUKON® and increased efficiency:

- The smaller footprint fits their shop well.

- The mitering capabilities of the SABER™ is capable of making a granite post or a waterfall edge with ease. Hatton Granite continues to learn, grow and expand. They are currently building a new facility and remodeling their business to have a larger focus on their countertops side, as it is the backbone of their business, today.

Technology, Partnership, and Success

Blake enthuses, “My heart is in the stone industry. I am a techie, so Moraware, Laser Products, and all things Park does excites me.” Blake thrives with change and is always excited to try something new. The Park Industries® training department knows Blake by first name because he enjoys being a pilot site with new software and such.

“Partnering with Park Industries® has changed my life. I do not go shopping around at other places. I am thankful for Park Industries® and I am happy to assist Park when I can because of everything we have achieved with their help. Park had a hand in building our business to the levels of success we have seen through the years, and have been our trusted advisor all these years,” says Blake.

QUICK FACTS

LOCATION

Hatton, North Dakota, USA

TYPE OF FABRICATION

Stone Countertops & Memorials

WEEKLY PRODUCTION

500-1,000 sq. ft.

NUMBER OF EMPLOYEES

Nine (Four in Countertop Fabrication Shop)

PARK EQUIPMENT

FUSION® CNC Sawjet, TITAN® 2600 CNC Router, SABER™ CNC Saw, FASTBACK® Edge Polisher, Pathfinder® Digital Photo Station

PARK PARTNERSHIP

Began in 2005 with a DESTINY CNC & YUKON Bridge Saw.