HydroClear™ PRO

Water System Series

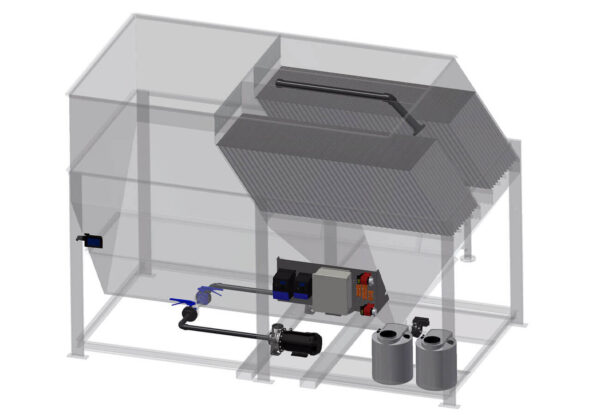

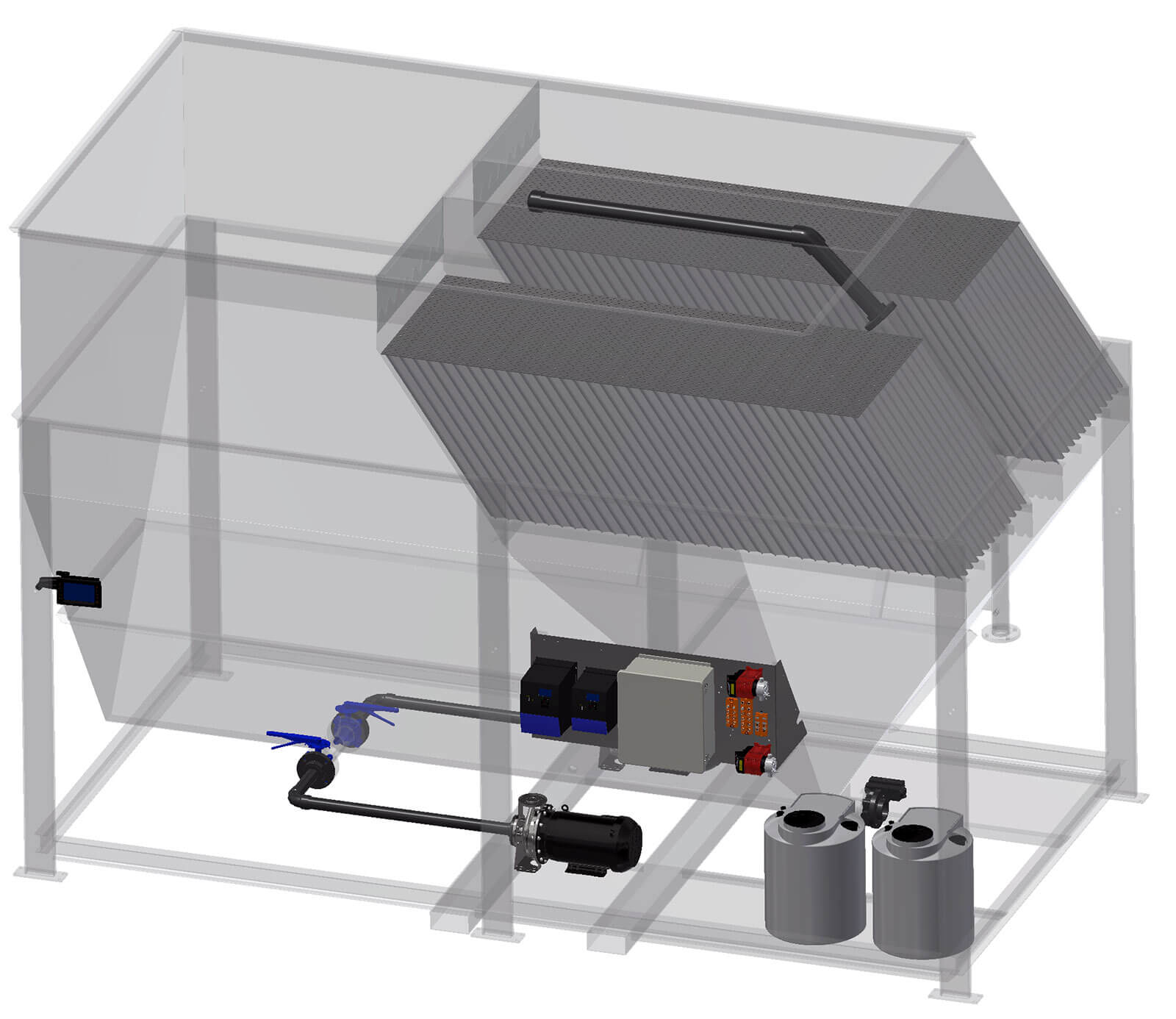

The HydroClear™ PRO Water Systems represent a new generation of water recycling. The PRO Series all-in-one design eliminates the need for a separate holding tank saving you precious floor space. It is available in 7 unique models, customizable to meet your shop’s water needs. The HydroClear™ PRO can accommodate up to 170 gallons of water per minute.

All In One

SystemEfficient

Recycling7 Models

Available

Choose your Region

Please choose your region and fabrication type below.

Watch Videos

Key Features

- Fabricate Responsibly

“Industrial activity accounts for about 20% of global water consumption.” – The average fabrication facility can use upwards of 80 gallons per minute to manufacture a countertop. Approximately 1,250 gallons of water is needed to produce a 50 sq ft countertop – equivalent to 20,000 8 oz glasses of water.

The HydroClear™ Systems utilize a closed loop recycling system that will enable you to reduce your water consumption by as much as 90% while being an environmental steward. As a responsible manufacturer, take care of your shop and the environment by installing a HydroClear™ Series Water System from Park Industries®.

- Efficiently Manage Your Water

Water is a critical element for your machines. Managing water in your fabrication shop is critically important to ensure high efficiency and productivity.

Park Industries® provides a variety of water system solutions to ensure you have consistent, high quality water flow to your equipment. The HydroClear™ PRO solutions will transform your shops water consumption and water quality all while significantly reducing your water bill. The cost savings are huge. With a HydroClear™ PRO system from Park Industries®, you could potentially reduce your water consumption upwards of 90% and your water bill by nearly 70%. It positively impacts your bottom-line as well as the environment.

- Customize a System

With 7 unique systems available, the HydroClear™ PRO Series can meet any fabrication production needs, able to handle up to 325 gallons / min.

Park Industries® offers an application engineering analysis of your facility. Through this consultation, Park will assess the current and future needs of your shop and make recommendations accordingly.

- Unique 4 Chemical System

The HydroClear™ PRO series from Park Industries® includes an exclusive, 4 chemical system that manages coagulant, flocculent, bromine, and pH levels. Each of the chemicals are monitored and automatically dispensed to ensure that the water is in spec. This hands-free, worry-free system will ensure that you are delivering the high integrity water to your machines. Available on the HydroClear™ PRO Advanced Series.

- HydroClear™ Pro Advantages

The HydroClear™ PRO offers an all-in-one system, loaded with new upgrades:

- HydroClear™ PRO Advanced Series – Features an Advanced Controller with an intuitive touchscreen monitor with real-time metrics (flow rate, water levels, etc), and much more.

- Pit Stir System (optional) continuously stirs the water and eliminates solids from settling in the pit, removing the need to clean out the slurry pit.

- A second Stage Polymer Feed (optional) additional tank and pump allows for dosing precise quantities of flocculant to the system.

- Status Notification Light Indicator shows you, at a glance, how the system is performing.

- Limited Ceiling Height Installation Kit (optional) for shops with low ceilings or cranes to work around.

Specifications

| Select up to 3 models to compare key specs | HydroClear Pro 35View Layout Drawing | |

|---|---|---|

| Gallons Per Minute | 35 | |

| Controller | Standard | |

| Repress Pump Motor | 3 hp | |

| VFD | NA | |

| Slurry Pump Motor | 1 hp | |

| Purge System (80 PSI) | Up to 2 cubic feet per minute | |

| Sludge Skids | 1 | |

| Tank Finish | Galvanized | |

| Footprint including clearance (L x W x H) | 54" x 99" x 151" | |

| Height with Ceiling Kit | 109" | |

| Weight | 2,500 lbs. | |

| Sustained Flow Rate (GPM) | 35 | |

| Peak Flow Rate (GPM) | 53 | |

| Endurance at Peak Flow Rate | 44 minutes |

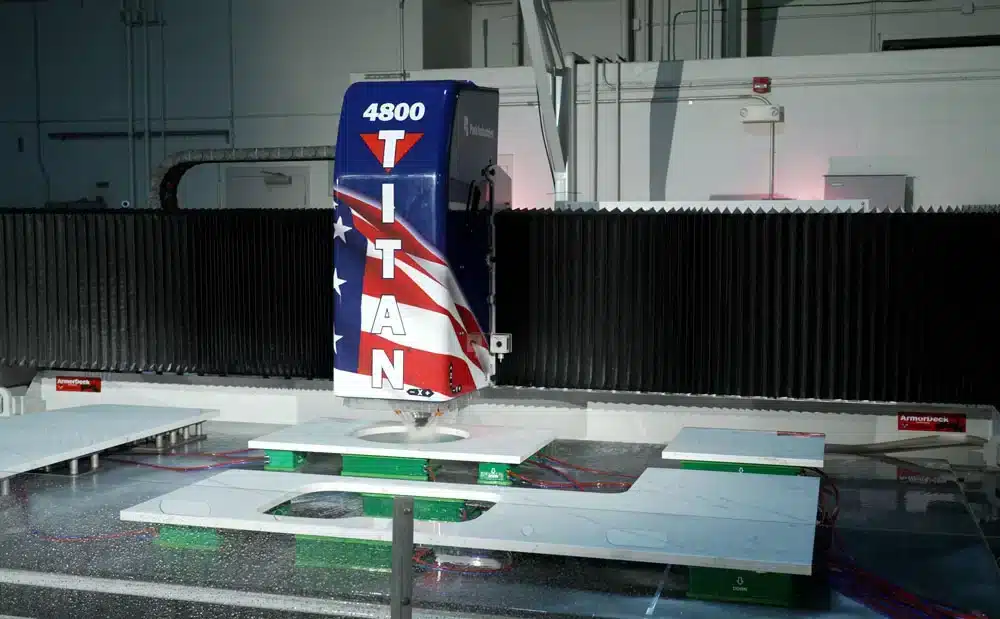

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.

The Hydroclear Pro 95 was a game changer for our shop. Before the Hydroclear we often had to halt production because of a lack of water. Our Hydroclear makes water on demand just as fast as we need it and now we never run out. It also requires very little maintenance and attention. We LOVE our Hydroclear!

Yes, I recommend this product.