An Over-cycle alarm can be caused by several things. This list is the best way to check off the easy items and quickly find the issue.

Check incoming water pressure. Be sure the main supply of fresh water for the cutting head hasn’t been shut off, or the filters aren’t dirty.

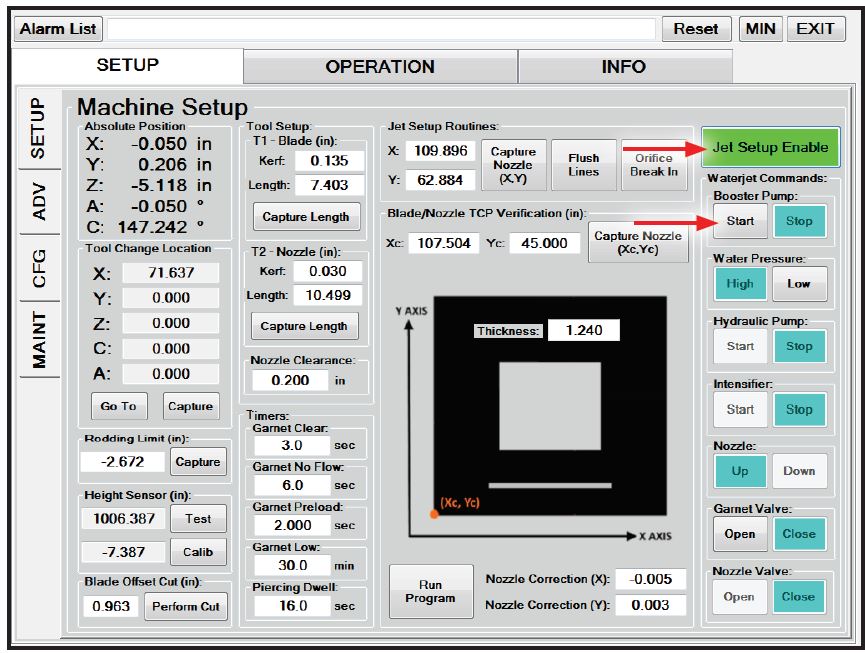

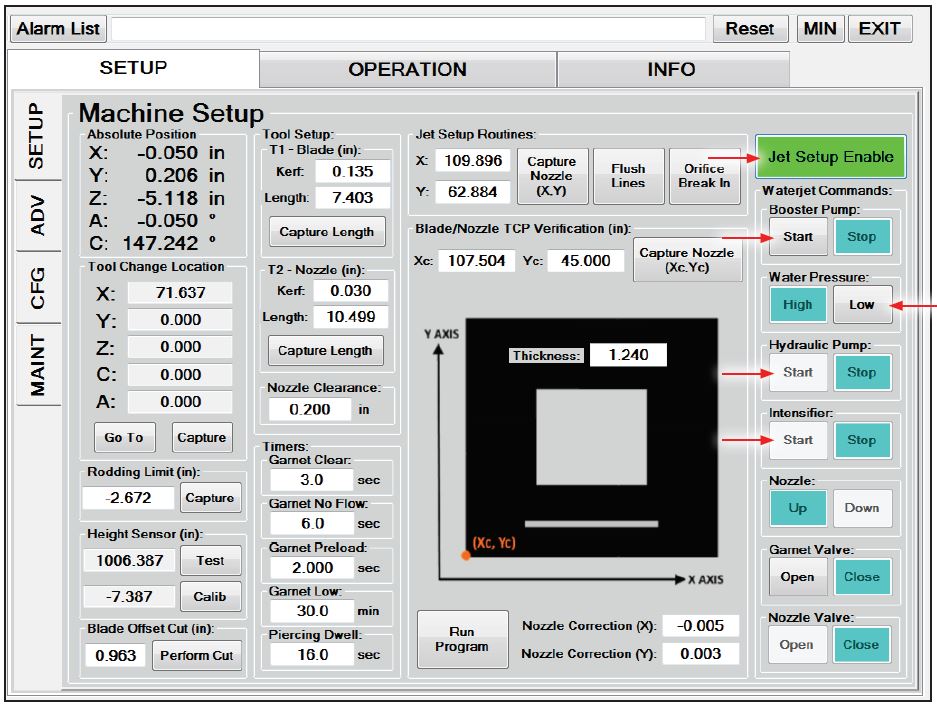

In the machine setup page:

a. Press the Jet Setup Enable button

b. Press the Start Booster pump button

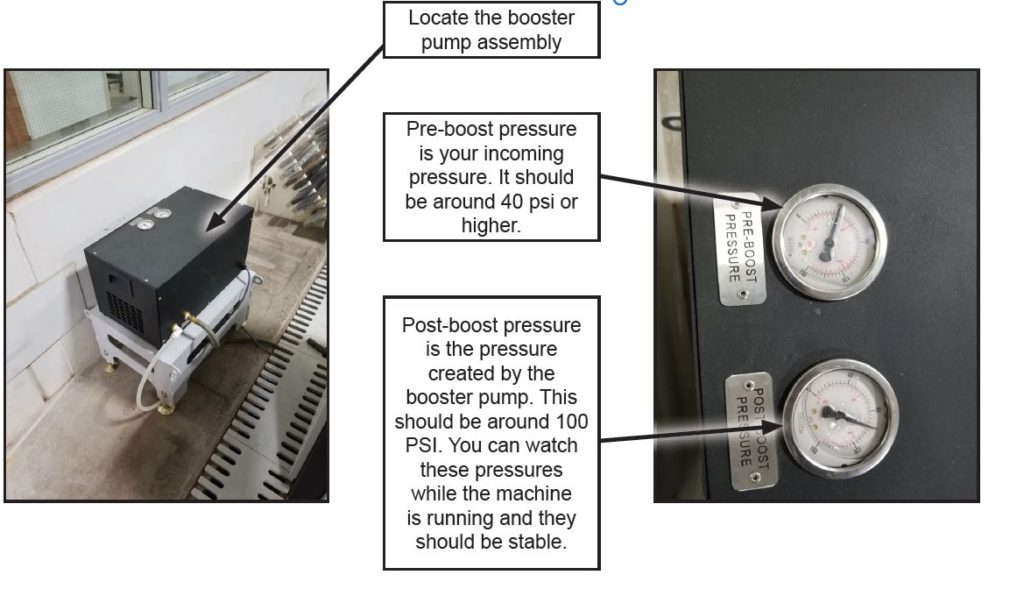

Verify your water pressure by checking the incoming pressure.

Verify the Pre-filter and post filter pressure on the machine.

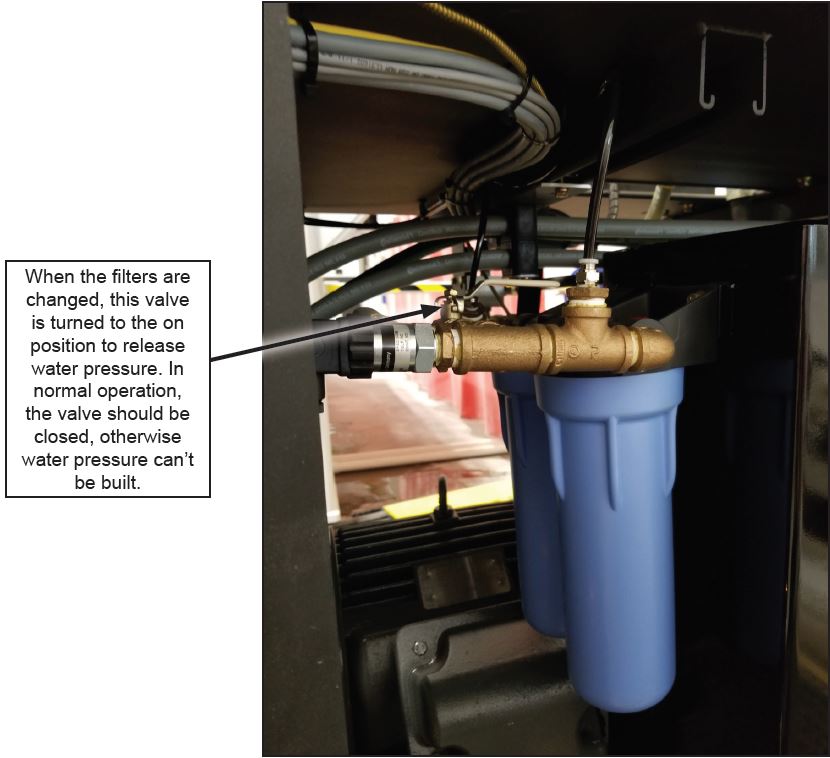

Verify the ball valve by the filters is closed.

If the water pressure is around 100psi on the pre-filter and post-filter gauges, turn the hydraulic pump and intensifier on. Start the intensifier in Low pressure first, once low pressure is reached, turn the pressure to High.

a. Be sure Jet Setup is Green, if not press the Jet Setup Enable button b. Press Booster Pump Start button c. Press the Water Pressure LOW button d. Press the Hydraulic Pump Start button e. Press the Intensifier Start button (Intensifier should cycle 6 times or less) f. When intensifier stops cycling, Press the Water Pressure High button, it should cycle 4 times or less

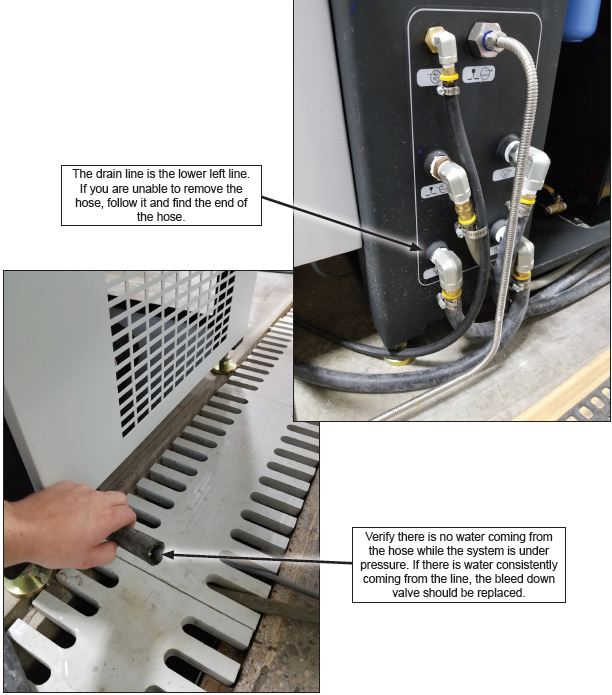

The intensifier should now be under pressure, the big gauge on the machine should be at or above 60,000psi. Verify there are no high-pressure leaks on any of the lines. If you find a leak, shut the system down so there is no longer any pressure on the system and repair the leak by either tightening or replacing the part. If no leaks are visible, check the intensifier, it shouldn’t stroke at all for at least 30 seconds. If it does cycle in the first 30 seconds verify the drain line for the intensifier has no water coming out of it.

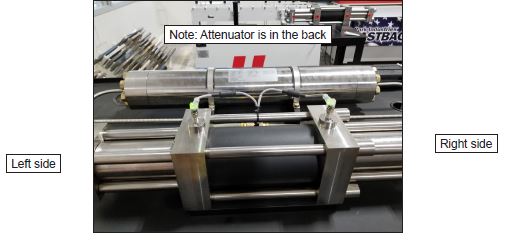

Open the cutting head and watch the big pressure gauge on the top of the machine. The pressure should only bounce 1000 – 2000 psi. If you notice it bounces 5000psi or more, there’s an issue with a poppet. If you notice it drops about 10,000 psi, holds for a second and drops another 10,000psi, this is a sign that there an issue with one of the poppets. Usually the machine will shut down quickly so there isn’t much time to watch it. Start the system up again and try it until you can get a good read on what’s happening. If it continues to shut down with an Overcycle alarm AND it’s always a right Overcycle, the right low-pressure poppet would be the first thing to check. You will need to rebuild the right side of the intensifier, be sure to lap the low-pressure poppet surface and also the check valve surface that the low-pressure poppet seats against.

Once the low-pressure poppet has been serviced check the system again. Build up to high pressure and see if you still have a large bounce in the gauge. If the bounce is still there and the pump is over cycling with the same alarm, replace the high-pressure poppets. These will need to be replaced, they can’t be lapped. All three parts, the poppet, the seat and the spring will need to be replaced.

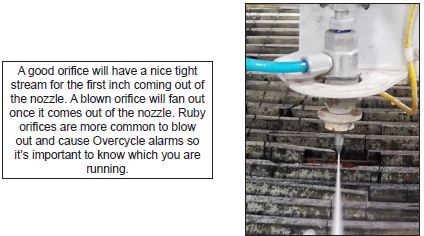

If the alarm persists, check the orifice. Lower the cutting head and blast water into the tank. Take note of the width of the stream. The stream coming out of the cutting head should be nice and tight, if it fans out, the orifice needs to be replaced. (If you are running a ruby orifice, this is very common, if running a diamond, it’s less likely).

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.