Stone fabricators rely heavily on machines to meet their customers’ needs. Selecting the right equipment is crucial for shops, whether they are just starting out or looking to upgrade from existing machines.

A hot discussion among stone fabricators is which machine’s better…a CNC Saw or a CNC Sawjet? And the answer is…it depends. Both machines offer a ton of production capabilities, but what is right for you depends on your situation.

To help you make the best decision for your shop, we’ll explain the key differences and strengths of each machine type and compare CNC Saws vs Sawjets.

What is a CNC saw?

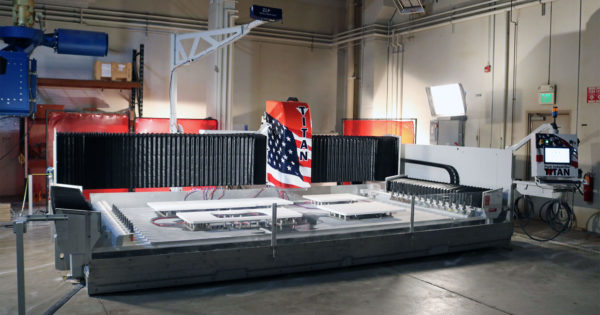

The basics: a CNC saw allows fabricators to program a layout and let the saw cut it out automatically using computer numerical controls (CNC). Stone cutting CNC saws, like the VOYAGER™ XP, are a popular choice for countertop fabrication and can perform cuts cleanly, quickly, and efficiently.

A CNC saw, especially a 5-axis one like the VOYAGER™ XP, utilizes its blade for straight cuts, miter cuts, straight line profiling, and even some arc cuts. For sinks, faucet holes, and radius parts, it uses tools and bits with its spindle.

With these milling capabilities, and innovative features like TightCut™ Blade Plunging, CNC saws can perform nearly any cut and offer tight nesting. They are an excellent choice for your first CNC machine or when upgrading from a bridge saw, as they also offer manual cutting capabilities.

Pictured: Park Industries® VOYAGER™ XP CNC Saw

What is a CNC sawjet?

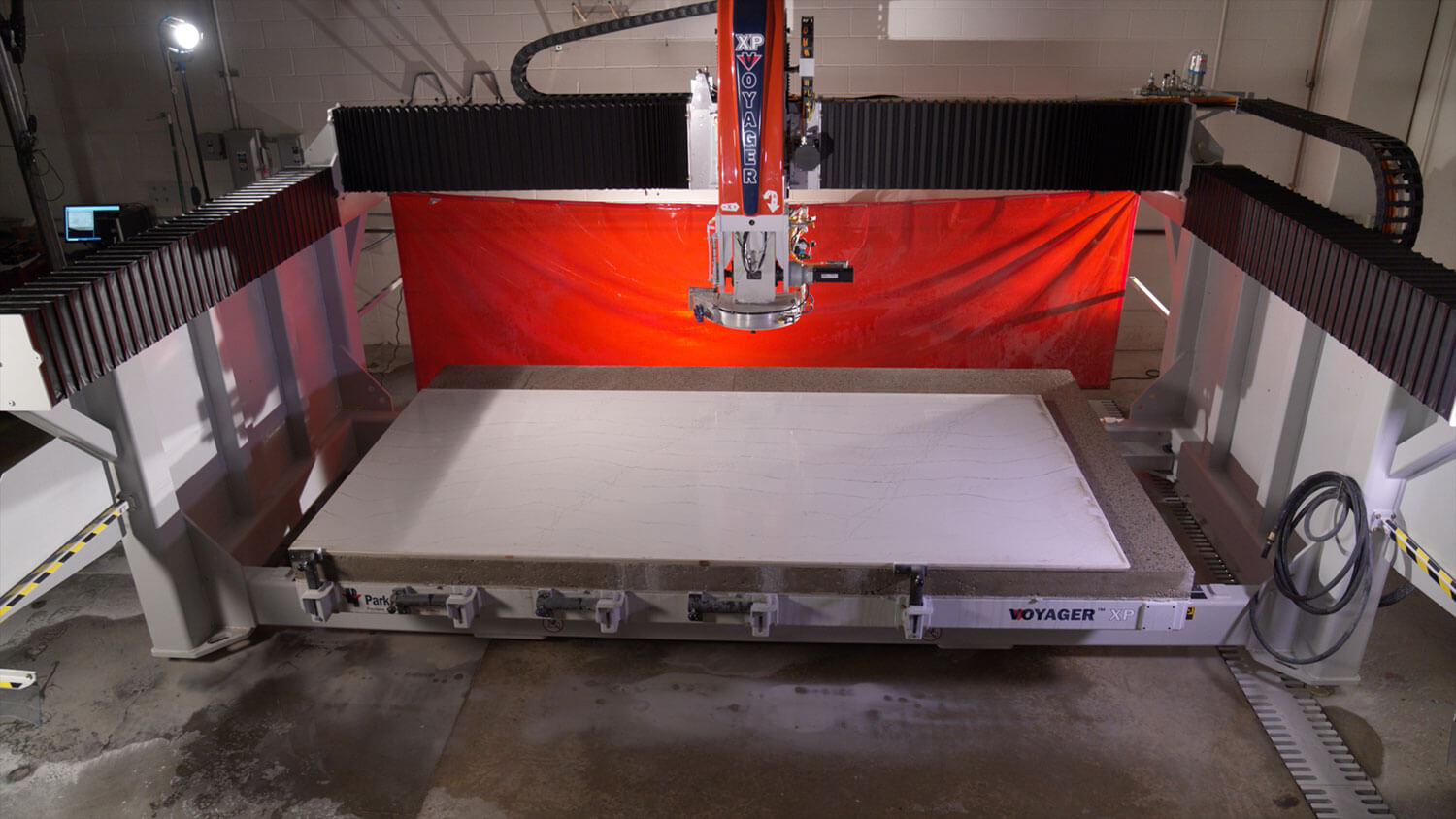

You can think of a CNC Sawjet as an upgraded version of a CNC saw. Both use a saw blade for straight and miter cuts, but instead of using a tool bit for sinks, tight nesting, and radius cuts, a sawjet uses its precision waterjet. This is the key difference between sawjets and saws. The waterjet cuts faster, tighter, and with more precision than a tool.

CNC Sawjets, like the SABERjet™ XP, are typically considered the “crème de la crème” when evaluating cutting solutions. They offer the highest level of production and with that, are a higher initial investment than a CNC Saw.

With the waterjet’s ability to make any cut without worry of running into parts, CNC Sawjets allow for faster finishing on CNC routers or significantly less hand fabrication. Sinks are the number one time saver on a sawjet.

The SABERjet™ XP is even able to miter arcs or inside miter corners with its waterjet. A sawjet can enable a shop to take on more jobs, including large commercial projects or complex custom projects, thanks to its waterjet capabilities.

Pictured: Park Industries® SABERjet™ XP CNC Sawjet

Comparing your options: CNC saw vs CNC sawjet

You know you want to cut with a CNC machine… now the question is which one?

Both machines offer excellent blade cutting, are extremely accurate and slice through a variety of materials like quartz, granite, quartzite, porcelain, and more. The key differences in performance are production speed and material yield. These really come down to tool vs waterjet. See why in the example below.

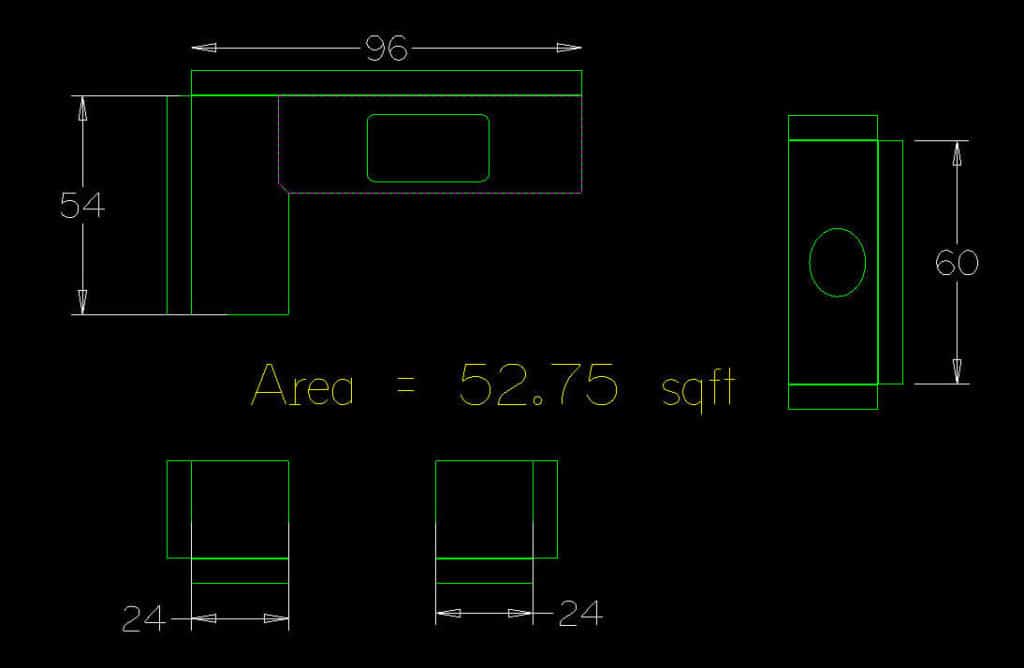

Use the layout below as “Example A“:

Example A: Common Kitchen Layout (52.5 Square Feet)

Example A Scenario: CNC Saw

A CNC Saw cuts this example well, but the multiple sinks and tight nests increase its time to about 58 minutes and require two slabs.

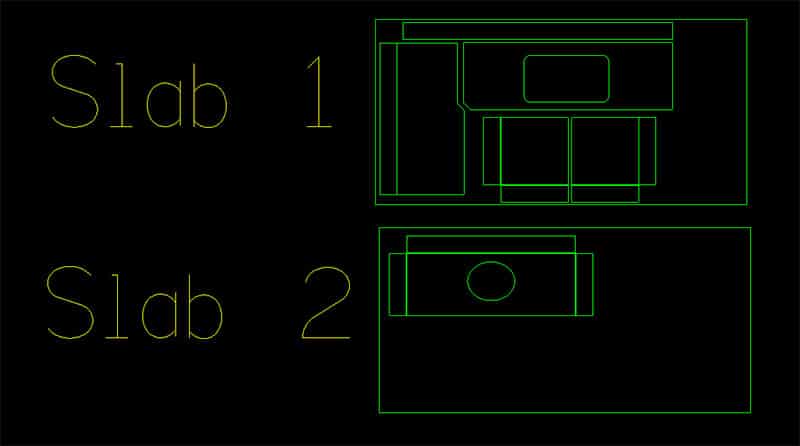

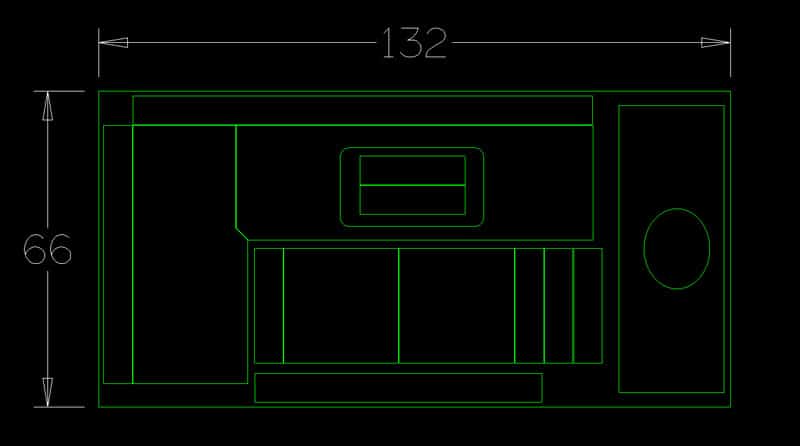

Here’s a preview of what the CNC saw program might look like, with two slabs needed.

CNC Saw Programs for Example A

Example A Scenario: CNC Sawjet

A CNC sawjet allows you to breeze through this example, cut this program in about 25 minutes and needing only one slab.

Below is a preview of what the program of a CNC sawjet might look like, tightly fit onto one slab.

CNC Sawjet Program for Example A

Investment

With an example like this, you may be thinking to yourself – why wouldn’t you choose a CNC saw? The CNC saw has one distinct advantage over a Sawjet: cost.

A CNC saw comes in at nearly half of the monthly payment, along with less operational cost and consumables due to no waterjet system. A CNC saw may be a better option for shops that need lower initial investment and want to keep things simpler.

Full Comparisons

Browse the comparison tables below to see CNC Saw vs Sawjet in the following areas: Cutting Production, Material Type, and Costs.

CUTTING PRODUCTION

| Area | CNC SAW | CNC SAWJET |

|---|---|---|

| Mitering | With Blade (Straight Miters Only) | With Blade or Waterjet (Straight & Curved Miters) |

| Material Yield Savings Nesting Requirements | 5-10% (1 inch spacing between parts needed) | 10-15% (No spacing needed between parts) |

| Common Line Cutting | Partial (Blade Cuts Only) | True (Any cut – Blade or Waterjet) |

| Oval Sink Cutting Time Example: Kohler 2210 Quartz Sink | 13 minutes | 2.5 minutes |

| Square Sink Cutting Time Example: Kohler 18″ 13″ Quartz Sink | 8 minutes | 4.12 minutes |

| Full Program Cutting Time Example A Kitchen Layout | 58:41 minutes | 25:45 minutes |

| Advanced Capabilities | Leathering Sloped Shower Pans Continuous Arc Cutting Straight Line Profiling | Inlays Curved Miters Continuous Arc Cutting Straight Line Profiling |

| Growth Potential | Good | Best |

| Impact on Shop / Labor | Good | Best |

Material Type

| Area | CNC SAW | CNC SAWJET |

|---|---|---|

| Granite & Quartz | Easy | Easy |

| Porcelain / Ultracompact Surfaces | Fragility of material makes radius work slower | Easy |

| Quartzite | Density of material makes radius work slower | Easy |

Costs

| Area | CNC SAW | CNC SAWJET |

|---|---|---|

| Consumables | Tooling bits (coring + milling), blades | Garnet, nozzles, blades, rubber slats, orifices |

| Monthly Financing 5 year term | $3100 | $5900 |

| Operational Cost Per Typical Kitchen (Approx 96 linear feet) Includes consumables, electrical, etc | $4.70 | $6.85 |

Saw vs Sawjet: Verdict

Most fabricators would agree that a sawjet is the higher production choice. If upfront cost isn’t a factor and you have the demand to warrant a sawjet, you can be confident choosing this option. Factoring in materials and labor saved with a sawjet, this style of machine offers excellent return on investment (ROI).

However, if you are new to digital fabrication, still use stick templates, or only produce a handful of kitchens a week, a CNC saw is a great option for you to upgrade to. The best way to determine your needs is by answering a few key questions:

- How much money can you save in labor with a sawjet?

- How much money can you save on materials with tighter nesting?

- Does your chosen solution allow for growth?

After thinking about these questions, a Park Industries expert can help you determine your Return on Investment (ROI). This will help you decide which machine is right for you!

Regardless of which you choose, get the best machinery & support

Park Industries® has served the stone industry since 1953. With our focus on precision, performance, and peace of mind, you can know that each piece of equipment we sell will meet your needs. Stone fabricators need the best equipment and understand what they should prioritize when comparing CNC sawjets vs. saws. If you’re still unsure, the team at Park Industries® is always here to have a friendly conversation and assess which is right for your shop.

Want the best equipment supplied by North America’s largest stoneworking equipment manufacturer? Contact us today and equip your shop with proven and profitable solutions, backed by the industry’s best customer support.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.