While many are still processing 2020, two years have passed and 2022 is here.

Stone fabricators have been resilient as ever – facing rising demand for countertops (yay), nearly impossible to find labor (now hiring?), material shortages, and other business challenges. Challenges, that may have some uttering, “We can’t keep going at this rate.”

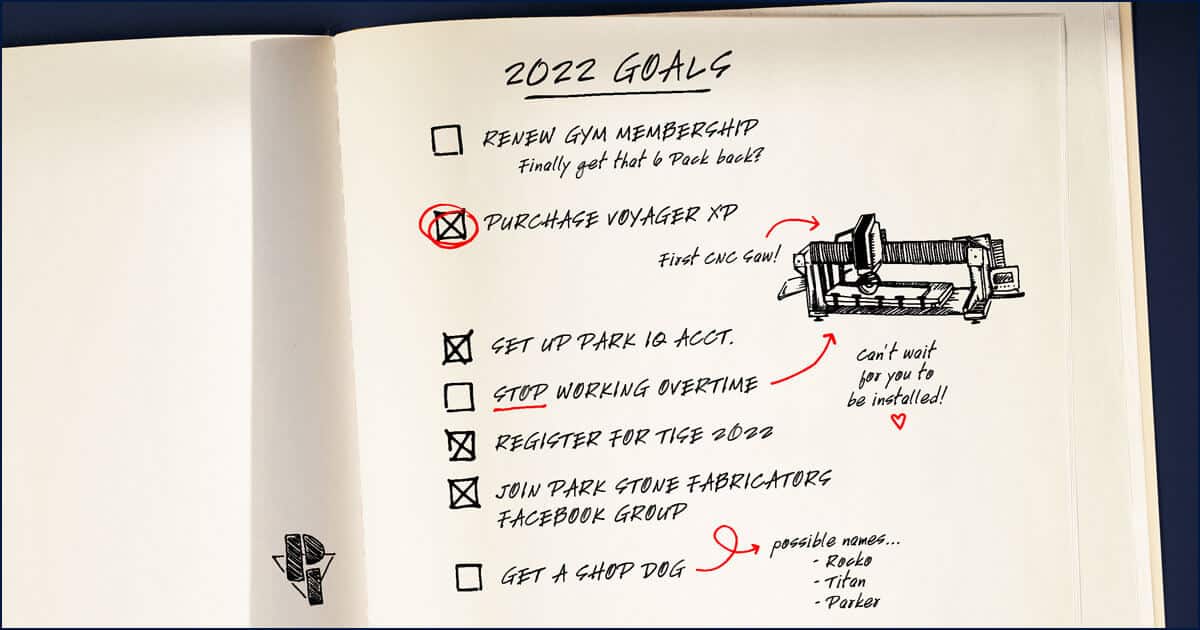

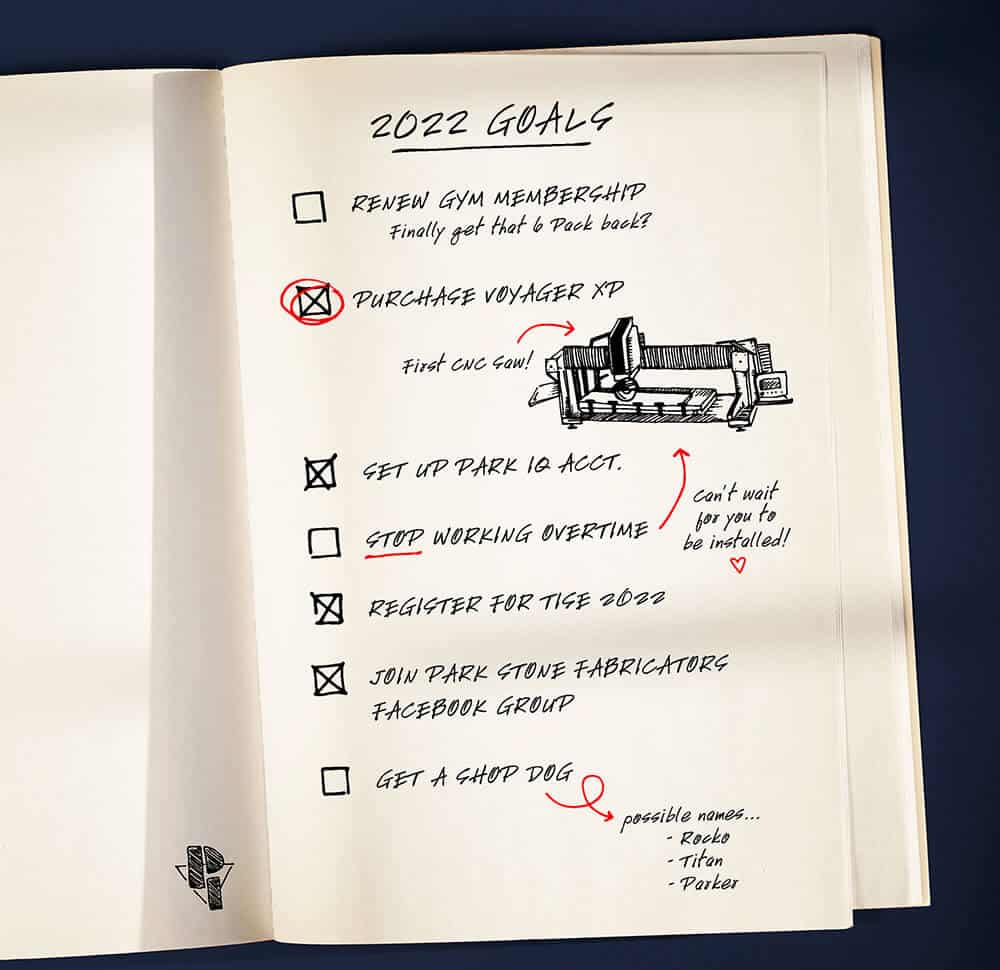

Now that we’ve experienced these obstacles, it’s time to prepare to overcome them. How will you change…what is on your business’s New Years Resolution list for 2022?

Park Industries® has a simple goal for your countertop shop in 2022: Stress Less, Produce More.

Ways to gain efficiency

The stone industry is no stranger to automation. Every few years, new technologies arise to help stone fabricators accomplish work faster than before while lowering costs and labor required.

With the industry’s most complete lineup of solutions, Park Industries® offers labor-saving machinery to help any shop gain efficiencies in their fabrication process, from start to finish.

Slab Management

Managing slabs and helping customers understand what they are buying can be a timely process.

With a digital photo station, like the Pathfinder®, you are able to create a digital inventory of your slabs. These powerful stations allow you to create 3D layouts to show customers exactly what their kitchen will look like and approve it, before you ever make a cut. With the “Perfect Match” feature, it also helps your programmer easily create the perfect vein-matched layout.

How this helps you? Better slab organization, more effective customer communication, and easier vein-matching.

Cutting, Mitering, Jetting

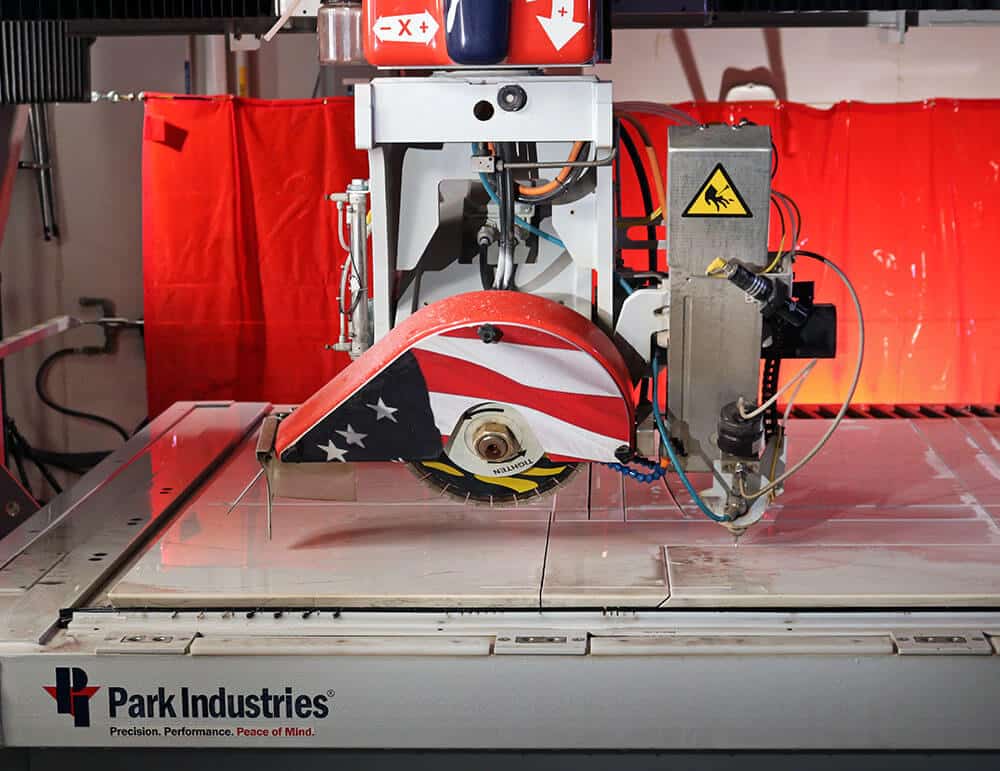

Cutting, or sawing, is arguably the most important aspect of fabrication. It sets the pace the rest of the fabrication process.

A CNC saw is a great first digital machine, where you can feel the impact the day you install it. Your cutting production becomes faster and you start saving big on labor later in the fab process. Most CNC saws, like the VOYAGER™ XP, come with milling capabilities – allowing you to drop sinks, faucets and more right at the saw table. Other features, like TightCut Blade Plunging, save precious time and material with tightly nested cuts.

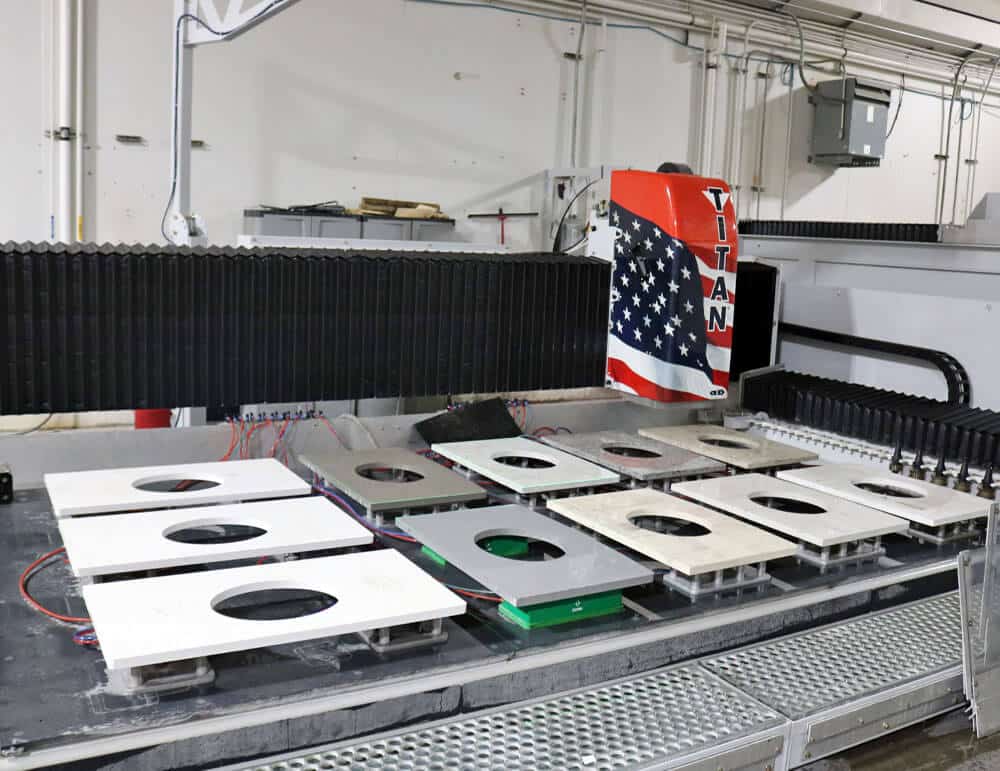

Some shops, that could be tight on space, opt to dream a little bigger for their first CNC. They may choose a 2 in 1 machine, like the TITAN® Fab Center. These machines offer both CNC cutting and polishing capabilities, making them extremely versatile in a smaller footprint.

The next level of CNC cutting brings us to CNC sawjets – aka the holy grail of stone cutting.

CNC sawjets utilize a waterjet instead of a milling/tooling bit like a regular CNC saw. Waterjet cutting brings unmatched efficiency and material yield. It quickly disconnects corners and drops sinks far faster than a milling tool. Sawjets are excellent for cutting high-production jobs or more complex, custom work.

CNC Sawjets, like the SABERjet™ XP, utilize a blade on straight and miter cuts as much as possible. The waterjet is then used to cut everything else the blade can’t, like radius or inside corner miters. Easily cut 20+ slabs a day on a sawjet by going with a two table sawjet, allowing you to cut on one table and load/offload on the other.

Lastly, shops who miter a lot or produce a high amount of porcelain / ultra-compact surfaces should look at a dedicated miter saw, like the CrossCut™ Deluxe.

Shaping, Edging, Polishing

With labor tough to find, it is hard to justify having a skilled fabricator spend their time polishing backsplash, especially when the FASTBACK® II Edge Polisher can knock out a full day’s worth of backsplash in about 15 minutes.

The FASTBACK® II polishes flat-edges at a rate of 65+ inches per minute with an exceptional finish – simply unbeatable. It can polish backsplash, vanities, and countertops.

A CNC router is the top choice for maximizing polishing efficiency. Machines that offer a large table, like the TITAN® 3000 Series, provide you the freedom to load up a table of parts, hit go, and walk away while it finishes them. This provides you or your operators time to focus on other tasks as the machine stays busy.

*Pro Tip* Earn a few hours of free production by letting your CNC router run over the lunch hour. If you live close to your building, start a program prior to leaving for the day.

Water Management of your Shop

In order to produce countertops efficiently as possible, your shop will require plenty of water flow to your machines. In the name of efficiency and the environment, a water recycling (like the HydroClear™ Pro Series) is a huge asset to your shop. Not only does it help you fabricate responsibly, it can save you significantly on your water bill and comes with extremely minimal maintenance.

Able to accommodate up to 170 gallons of water per minute, the HydroClear™ Pro will allow you to take control of a vital resource for your shop: water.

Tracking & Optimizing

After you add all of this CNC machinery, you will be well on your way to efficiency gains! But how do you track your production? A machine intelligence software like Park iQ™, allows you to monitor your CNC’s production, tooling, and status from anywhere.

With a live dashboard, in-depth reporting, and other helpful features available 24/7 – it is an asset for shop managers or owners to easily identify bottlenecks and add to their resolutions list.

Why is now the time to automate?

➜ Meet current demand with less labor

➜ Automate now to stay competitive in the future

➜ Lead times are higher than previous years

For the right partner to help you automate your fabrication process, there’s an easy choice. Park Industries® offers the best machines for precision, performance, and peace of mind, with dedicated support at every step of the journey.

Contact us today to revolutionize your business and start crushing your 2022 goals to produce more and stress less.

*Bonus*

We asked fabricators for their 2022 resolutions

Answers via social media:

- “Get our yard filled with 200-1000 slabs”

- “Buy Park Industries machines”

- “Stop using granite puns 🥴”

- “Definitely buy another machine from Park, it’s been over 6 years now. We still haven’t had an issue 🙌”

- “To own a Park HYDRASPLIT, the best there is.”

- “Get back to TISE in Vegas!”

- “Master this new bad boy (SABERjet XP CNC Sawjet)”

- “Add the TITAN 3700 to my shop! put it right next to my VOYAGER XP!”

- “Get a shop dog”

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.