Summer is already halfway over, and while demand for countertops has been high, the true busy season for fabricators is on the horizon.

The Holidays are a joyful, yet busy time of year for most people in their personal lives. For stone fabricators, demand typically peaks as last-minute requests come in, with customers needing that countertop like yesterday so their Thanksgiving food can have some new Quartz under it.

Without proper planning, the shop can get hectic scrambling to meet tight deadlines. Mistakes seem to happen more and more, while stress may reach a boiling point. With the proper planning? You can navigate it efficiently and take full advantage of eager customers…cha-ching.

Here are a few tips from both Park Industries® and real fabricators to help you dominate this year’s busy season.

Organize, Organize, Organize

This was the number one answer from fabricators! Make time in your schedule now to get your shop cleaned up and organized. Same with any processes that feel messy.

For managing your materials, you can utilize a system like the Pathfinder® for keeping a digital inventory of slabs and remnants. Then bring in a process like SPEEDlabel for tracking your parts as they flow through the shop.

Communicate it well with your team too and iron out ways to make organization and cleanliness part of the foundation in your shop. Then when busy season truly hits, you’ll be able to dominate day by day.

Staffing

We know…labor is tough to find right now. That said, you need to make sure you have the staffing in place to meet the likely spike in your business. If you need additional help, now is the time to turn up your recruiting efforts as you may not want to worry about hiring or training during the Holidays.

A few other helpful tips for staffing:

- Cross-train. Make sure every position In the shop has a backup…If a fabricator, programmer or machine operator leaves, will your business stall?

- Get any time off requests now or request they happen outside of peak demand. This may be a hard pill for them to swallow, but they will appreciate the notice and communication.

- Consider more seasonal temp help that may be more green, but can still help as an extra set of hands in the shop or on installs.

Machine Maintenance

Now and the months leading up to holidays are the time to zone in on machine maintenance! You may not have the time you need for it once extra jobs start rolling in. If you get your machines in tip-top shape now, you reduce the chances of unplanned downtime while you need to be cranking out tops.

For Park Industries® customers, consider utilizing our ProGUARD™ maintenance program for a proactive approach to machine maintenance and ensure your machines don’t encounter unplanned downtime. You can schedule a health check to assess your machine(s) needs and even have a Park Industries® technician perform the maintenance for you.

Spare Parts & Consumables

Sometimes, machine downtime can be limited to a few minutes by having the right parts on hand. Stocking up on extra parts for your machines, especially for ones you know you will use like consumables, is a great idea to help prepare for the busy season.

For Park Industries® customers, while we can get you a part typically In 24 hours, it’s still not as fast as having at your shop ready for when you need it. See this scenario to see how a proactive approach with parts can save you thousands:

Park Industries® has even put together kits for consumables, spare parts and maintenance to make it easy to order the parts you need.

| PROACTIVE Approach | REACTIVE Approach | |

| Diamond Orifice Cost | $425 | $425 |

| Shipping | $25 | $134 |

| Downtime | 10 Minutes to Replace | 7 Hours Overnight Shipping + Replacement Time |

| Downtime Costs @ $1,500/hour | $250 | $10,500 |

| Total Cost | $700 | $11,509 |

Identify Bottlenecks & Optimize Your Shop’s Workflow

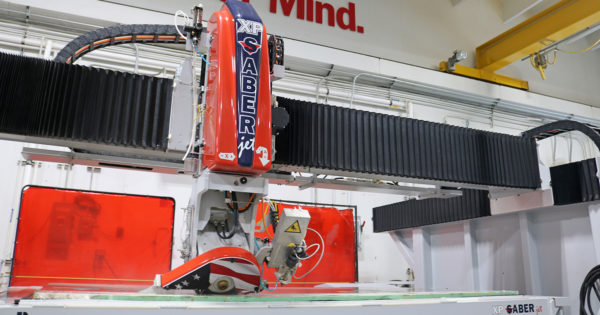

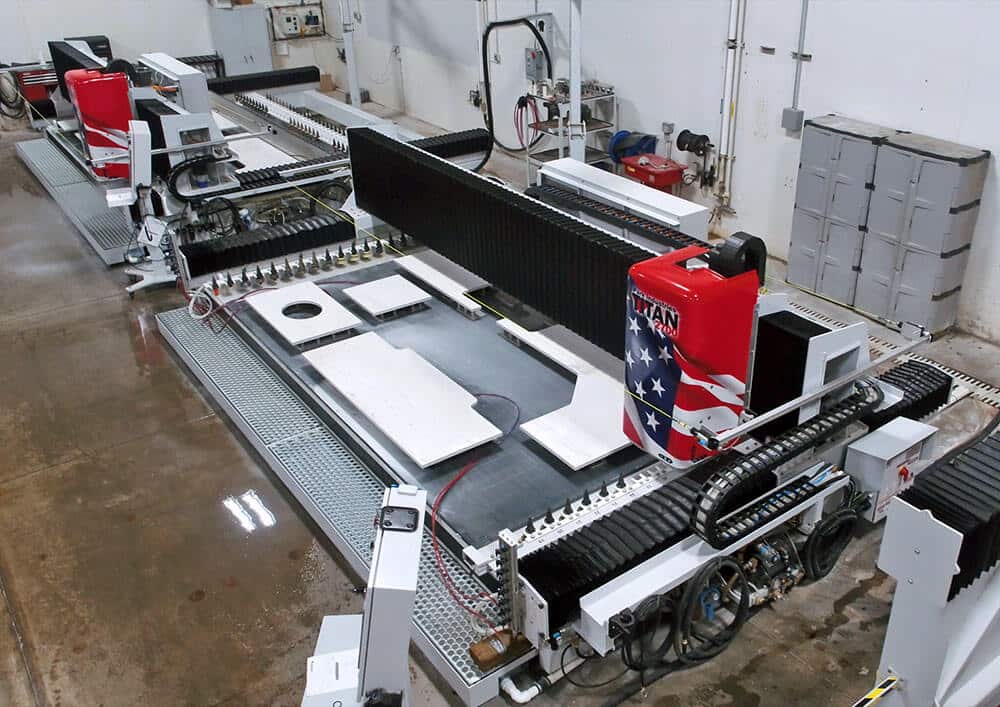

Assess your shop’s workflow for bottlenecks and add new machines as needed.

- Is your saw taking too long to load? Maybe it’s time for an overhead crane system.

- Are you really waiting to install that job because the backsplash isn’t done yet? Time for a FASTBACK® II.

- Does the flow of your shop make sense? Reimagine it if not.

- Replacing an old machine with an upgrade could increase your production capacity enough to offset the cost of the investment.

Park Industries® consultants, with a combined 250+ years of knowledge, can help walk you through bottlenecks, layout your shop for ultimate efficiency, and assess your production needs.

We hope you found these tips valuable and that they will help you prep for and DOMINATE the busy countertop season approaching. And as always, the best way to crush your production goals is with reliable, efficient stone machines from Park Industries®.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.