The next generation of TITAN® brings tons of improvements and upgrades for the leading CNC router series. See “What’s New?” on the TITAN® 3000 series.

Redesigned For Speed

- Faster tool changes.

- Improved spindle torque for faster speeds.

- Increased water flow, ideal for high-speed tooling.

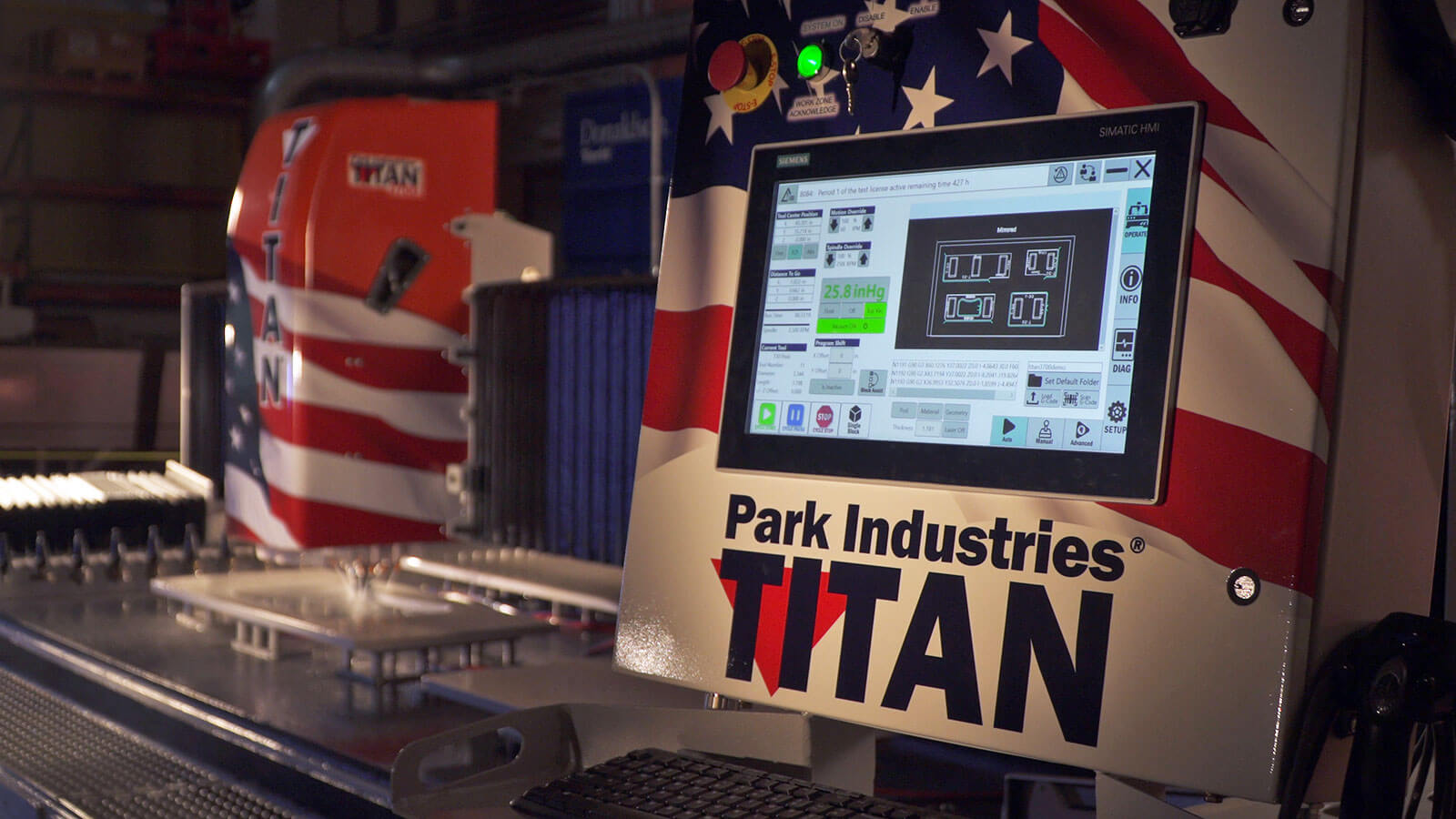

HMI Station & Interface Improvements

- The HMI station is now connected directly to the machine and protected against the wet, harsh environment of the shop floor.

- The interface has been completely redesigned, now easier to navigate and more intuitive

- Ability to assign different levels of control to each operator.

Operator Improvements & Automation

- Automatic tool pocket calibration resets tool pockets quickly.

- Improved ITM setup functionality, including:

- Faster tool setup process.

- Tool Library includes a semi-auto upload feature.

- Ability to import/export from offline tool measuring devices.

- Improved block assist function, allowing fabricators to adjust tool paths within a block.

- Blick® manifold optional upgrade. The manifold can be mounted in various positions for easy access.

- Vacuum pressure alarm. If the pressure is too low, the machine shuts off to protect the pods and material from damage.

- End of cycle/job progress light indicator.

- New laser for pod/material placement with calibration feedback. This notifies the operator of the successful calibration.

- Spindle usage tracking – meter hours.

Maintenance Improvements

- Redesigned for better water flow and less maintenance.

- Auto lubrication system for all bearings…saves around an hour of maintenance previously needed for manually lubricating bearings.

- Easier serviceability and quick disconnect with the ITM system.

- The spindle gripper set can now be snapped back into place.

- The set screw has been removed and re-designed for quicker maintenance with fewer failures.

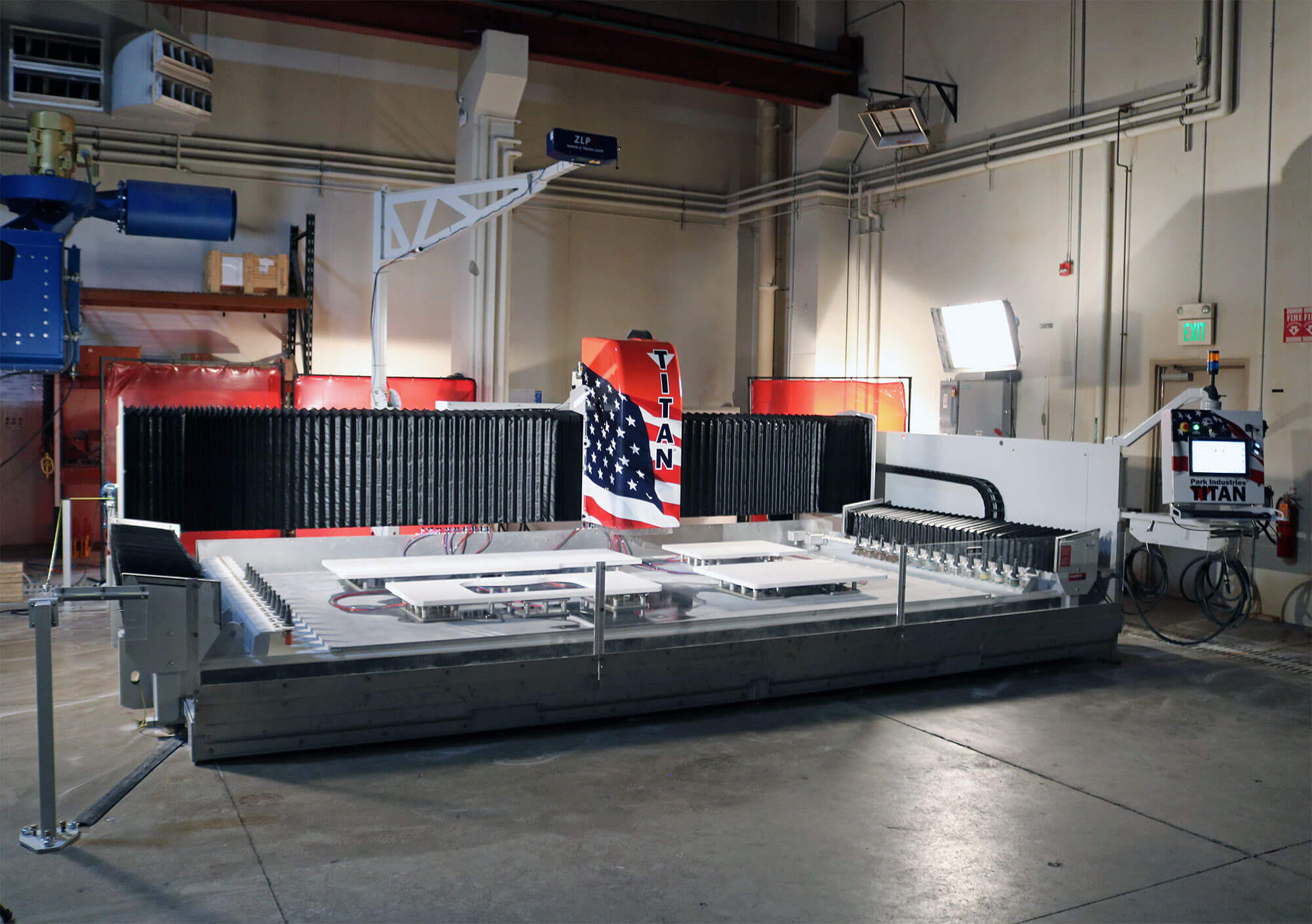

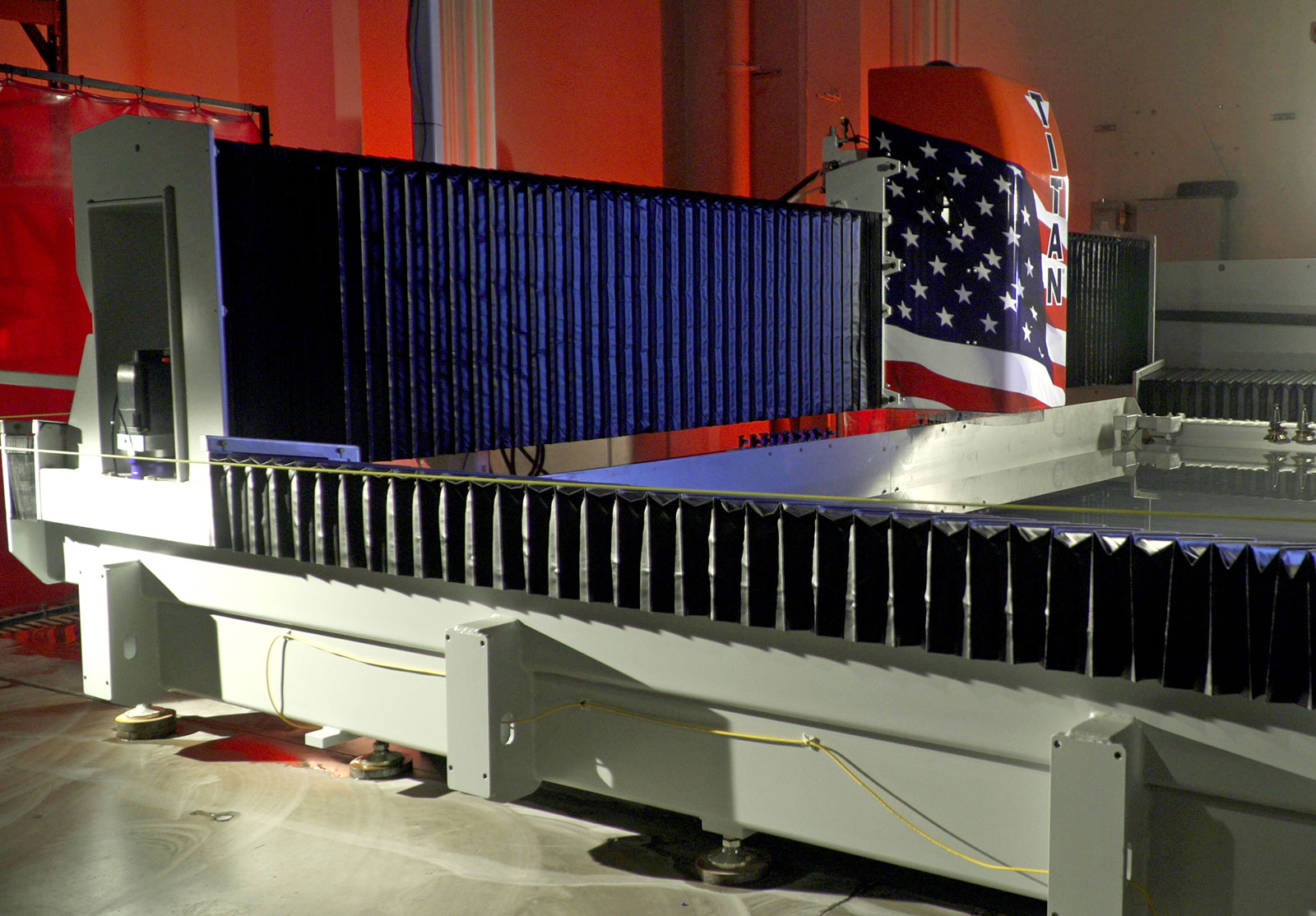

Design Improvements

- Bellow covers now use aluminum plates and has fewer screws. Screws are more accessible, secure, and easier to remove.

- Rails are better protected with the new bellow covers, making it nearly impossible for water or mud to get on the rails of the machine.

- New shroud with side handles that can be removed by a single employee (two-person assistance with TITAN® 2000 models).

- Shroud allows for water union visibility and easier access to the spindle.

- Added spindle protection to control dust and mud, extending the life of the spindle.

- Spindle sensor detects a belt break, shutting the machine off, preventing further damage to the spindle or tooling.

- The optional water containment system reduces water spray.

Safety Features Added

- Laser Photo Eyes added – front and back safety beam.

- Increased convenience (compared to cable) for loading/unloading. Safety cable system around the entire machine.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.