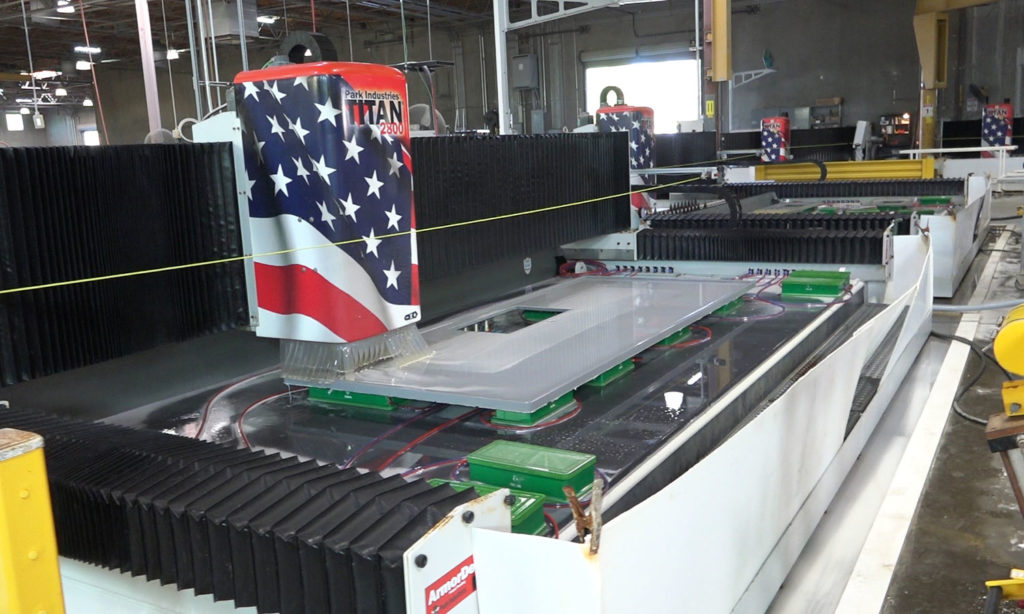

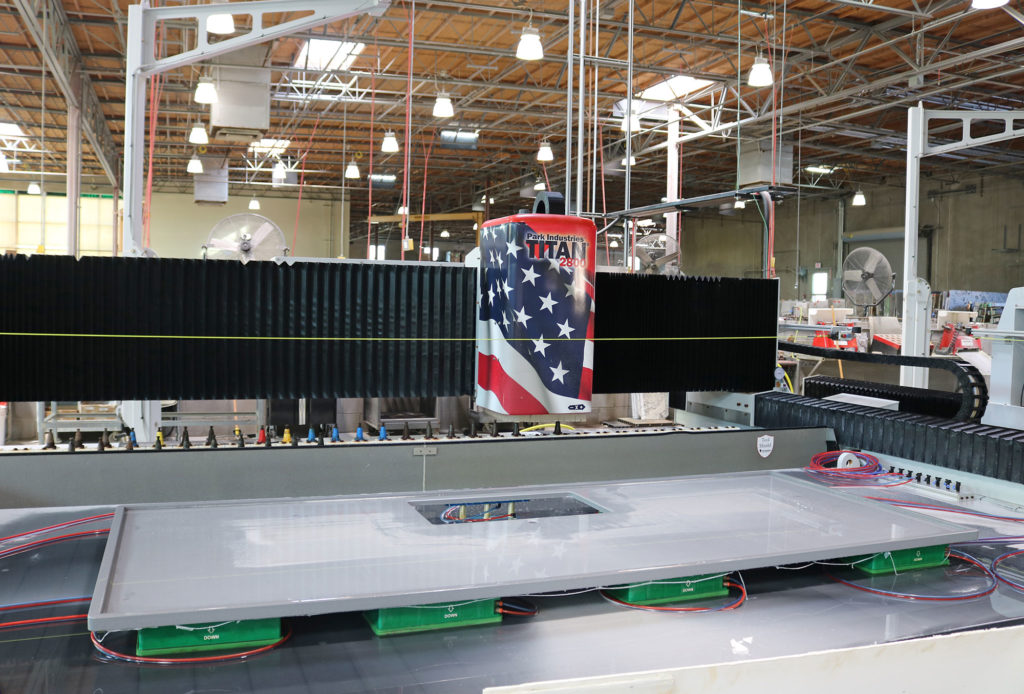

Equipped with seven TITAN CNC Routers and three dual-tank FUSION CNC Sawjets, Rick Bayne of Mesa Fully Formed runs a high-production stone shop where reliability and machine uptime are of the utmost importance.

Mesa Fully Formed

With over 50 years of fabrication experience, Mesa Fully Formed has become a leader in the Arizona countertop and bath industry. They fabricate, install, and service a wide range of surfaces for their customers.

Their stone production has grown tremendously since they started offering it in 1998. Rick Bayne oversees their stone division and has found Park Industries® machinery to be the reliable equipment they’ve needed to help meet their goals.

Read their story! Expand the sections below to learn more about Mesa Fully Formed’s story and their partnership with Park Industries®.

50 Years & Counting

Humble Beginnings

Larry Cassaday started Mesa Fully Formed (MFF) in 1969 working out of a small shop that almost exclusively worked in laminate. They later expanded into cultured marble, and in 1998 added granite to their material lineup. Today, they have about 300 employees and operate out of five locations in Arizona and offer a broad line of material options including marble, granite, and a variety of different natural and engineered stone materials. They have about 25 employees in their stone fabrication shop.

Equipment Made in the USA

Rick Bayne, the Granite Shop Manager at MFF, recalls starting their stone fabrication with Italian-made machines, which they often lacking in quality and difficult to receive support from the manufacturers. Trying to get service for those machines always involved the frustration of a big time difference across several time zones. Rick labeled that time for their shop as “Just an awful experience.” He knew he needed to make a change.

After hearing good things about Park Industries® from several fabricators, they made the switch to American made. With Park, they got “a good, quality machine,” and the only time difference Rick would have to deal with was an hour or two, which made all the difference in the world. Pun intended.

Go Big or Go Home

Digital Expands Capacity

Having started with manual bridge saws and inline profilers, the benefits of going digital were immediately apparent. Mesa Fully Formed leverages digital templating, SlabSmith, and CAD operations, paired with multiple dual-table FUSION® CNC Sawjets. Its two-table design allows you to process stone on one side while unloading and reloading on the other table. Rick comments, “Knowing how much effort it took on a bridge saw to cut a job, and then even after it was cut, the corners, cleaning the corners, all the work. And then to look at a machine that cuts all the radiuses, inside and out, cuts the sinks, it’s my favorite.”

The More the Merrier

Mesa Fully Formed also boasts multiple TITAN® CNC Routers. And, by “multiple,” we mean seven of them!! If you’re a fan of Park equipment, to stand in Rick’s shop and take in the magnificent sight of seven TITAN’s arrayed across the expanse of their very large fabrication facility is an awesome thing indeed. Rick enjoys the fact that very little finishing is required when the machine is done. He shares, “Realistically, other than checking the edges for minor pits or little chips, they’re coming off of the TITAN’s install-ready.”

Big Capacity, Big Opportunity

Machine Uptime Over Everything

When you have seven TITAN’s, multiple FUSION’s, a FASTBACK® II Edge Polisher, and more at your disposal, you’re able to do some pretty amazing things. Because of their impressive machine lineup and commitment to quality, Mesa Fully Formed has been able to complete some exciting jobs. Rick shares, “We’ve done casinos; 500 rooms with tub decks and ADA vanities. One of the coolest is a sixty-foot radius bar that we did. We took a picture of about twenty-five of the finishers inside the bar, which is pretty neat.”

All in all, Mesa Fully Formed has the ability to process 60-70 slabs per day, and Rick speaks highly of Park’s customer service, machine quality, and engineering. He goes on to share how Park has contributed to his success, “We wouldn’t have reached our goals if we didn’t have equipment that could get the job done. Your guys’ equipment got the job done.”

QUICK FACTS

LOCATION

Mesa, Arizona, USA

TYPE OF FABRICATION

Stone Countertop

DAILY PRODUCTION

60-70 Slabs per day (two shifts)

NUMBER OF EMPLOYEES

300 (About 25 in Stone Fab Shop)

PARK EQUIPMENT

FUSION® CNC Sawjet (x3), TITAN® CNC Router (x7), FASTBACK® II Edge Polisher (x2), YUKON® Bridge Saw, Pathfinder® Digital Photo Station

PARK PARTNERSHIP

Began in 2001 with a JAGUAR® Bridge Saw.

Featured Machines

PHOTO GALLERY

Contact Us

Ready for an upgrade?

Request information and we’ll respond promptly to discuss adding Park Industries® machinery to your shop! Or find your sales representative.

6301 Saukview Dr

St. Cloud, MN 56303