Raised on hand fabrication with a craftsman’s mindset, Troy of Stone Works International, found a new love for stonework after pulling the trigger on a pair of CNC machines from Park Industries®. Not to mention, his shop is cutting faster and more efficiently than ever before.

Stone Works International Inc.

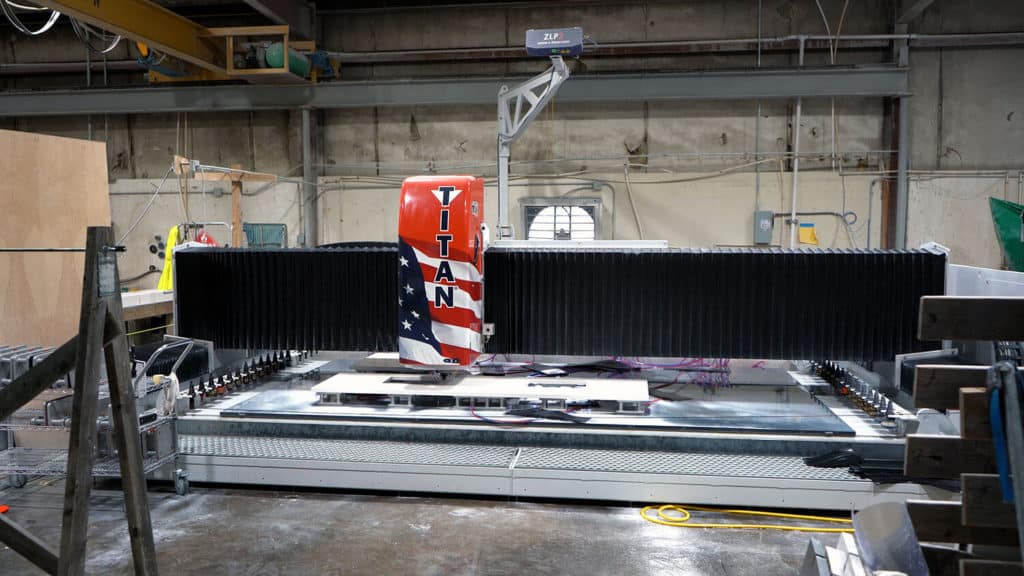

With their sights set on success and an “all in” mentality, Stone Works International Inc. increased their production with the addition of a Park Industries® trio package including: a VOYAGER™ XP CNC Saw, TITAN® 3700 CNC Router, and Pathfinder™ Digital Slab Station.

After decades of hand fab, they are now 100% fabricating digitally with more production and efficiency than ever.

Read their story! Expand the sections below to learn more about their story and partnership with Park Industries®.

From Teenage Fabricator to Shop Owner

As a sprightly 16-year-old Troy Naylor entered the stone industry, learning how to work hard and with his hands. He’s a “go until the job is done” kind of guy. For years he wasn’t remotely curious about the use of automation in a stone shop. He’d go as far as to bet people who owned CNC’s that “he was faster at fabricating then their machine was.”

In 2002, he established Stone Works International Inc. (originally named Naylor Marble & Tile) in Eugene, Oregon,. After nearly two decades of continuing to fabricate the “old school way”, he began brainstorming future business ventures. Troy knew the time had come to supplement his years of fab experience with CNC machinery. He also knew being a complete novice (who didn’t even own a computer at the time) that he couldn’t make this change halfway. If a CNC machine was going to enter his shop, everything else in the production line needed to operate and communicate on the same scale.

With his betting days (mostly) behind him, and his own company’s success in front, Troy began the search for a partner who could provide not just high-quality machines, but also the reliable customer service he knew needed to learn how to operate and utilize digital machinery. This journey led him to the Park Industries®. In the fall of 2020, he added an entire digital trio of equipment including the VOYAGER ™ XP CNC Saw, TITAN® 3700 CNC Router and Pathfinder™ Digital Imaging Station.

Learning a Second Language

For some “seasoned” fabricators, getting into CNC technology can seem like a daunting learning curve. It’s a large financial decision, and suddenly a piece of equipment is sitting there, staring you in the face while you figure out how to make it move. Troy was happy to experience how helpful Park Industries® was with their transition. He felt that he could call weekly if needed and say, “Hi, it’s Troy – here’s what I need to learn today.”

He felt Park’s service team was as high-quality as the machines.

Initially after the purchase, Troy caught himself wondering what his role would now look like with automation in his shop. There wasn’t much to consider – if he wanted to stay involved in the production process, he’d have to commit to learn and operate the machines, even though he thought he’d fail at it. “I was wrong,” he states simply. “It’s pretty great, especially at my age, to be able to not only keep up, but produce more.” When things need to get done, his reliance on others is minimal. “I can keep us on schedule by myself, and that’s something I find extremely gratifying.”

Best Advice – Dive Right In

Troy wasn’t going to just dip his toes in the water – he dove headfirst into the deep end.. He sought full access to the potential benefits his shop could experience with the help of CNC machinery. “It might have been an easier learning curve to just introduce one machine at a time,” he laughed, “but eventually you will need them all. Only having one or two parts of the equation, you’re not going to be able to do as much as what’s possible.”

With this mindset, no one machine tops another in Troy’s eyes. Just like his employees, each machine serves its own purpose, and works in union with its counterpart to produce a finished product.

Tools for Growth

A move into automation was the start of “future proofing” success at Stone Works International Inc. There were three challenge areas that required attention as the company grew: increased competition in the industry, potential shop downtime, and hiring qualified employees.

With the combination of fast, precise, never faltering work CNC machines offer, many shops have seen the benefits and adjusted their system. This translates to increased service options for customers, with attention to detail that may not have been achieved before. Though Troy is still learning how to use his Pathfinder digital solution, he says it’s the tool you have to have. “Without the digital information it provides, tracking the tiniest veins to this level of precision just wouldn’t be possible,” he states. “You could spend hours moving pieces around trying to line it all up, or you could use this technology and test out 30 scenarios in three minutes.”

Furthering the “time is money” idea, the second member of Troy’s machine trio allows him to get out the door and home for dinner at a reasonable hour every night. The VOYAGER™ XP 5-axis CNC saw allows Troy to sit at his desk and plan out every cut for 15 jobs before moving into the shop to stack, rack, and ready them for the table. “My previous machine couldn’t handle this high of a workload at once,” he said, “but the VOYAGER™ XP just punches them out.”

Even with a top-notch team like Troy is lucky to work with, production halts happen, and a growing market only waits so long for recovery. The TITAN® 3700 CNC Router was the final piece of the puzzle helping Stone Works International Inc. avoid downtime and reduce time spent recruiting staff. “The biggest thing with the TITAN® is I can have a bunch of slabs cut, my whole staff can leave, and I can operate it by myself,” Troy said. “Even when there’s a setback during the week, instead of begging four men to work on the weekend to get us back on track I can just say “see you later,” finish them up myself, and be ready for Monday.”

Troy’s bottom line advice: “Even if you’re like me and you know nothing, just take a deep breath and a small bite out of it, and you’ll see how rewarding going digital is. And you couldn’t pick a better company to do it with than Park Industries®.”

QUICK FACTS

LOCATION

Eugene, Oregon, USA

TYPE OF FABRICATION

Countertop

NUMBER OF EMPLOYEES

5 in Fabrication Shop

PARK EQUIPMENT

VOYAGER™ XP CNC Saw, TITAN® CNC Router, Pathfinder™ Digital Imaging System

PARK PARTNERSHIP

Partnered with Park Industries® first in 2020 with a VOYAGER™ XP & TITAN®.

Photo Gallery