A partnership with Park Industries® of nearly two decades has helped Carolina Custom Surfaces grow from a manual shop, to an award-winning fabrication company and leader in the Southeast.

Carolina Custom Surfaces

Joe Duszka, President of Carolina Custom Surfaces in Greensboro, North Carolina is laser-focused on growing and diversify his business wherever he can. With a background in manufacturing operations, his goal for the company is simple: be efficient and have great return on investments.

Carolina Custom Surfaces (CCS) was founded in 1995 as a cultured marble and solid surface company. In 2006, they made a decision to grow their business by moving to a new location and adding a stone shop.

It was then that a fellow ISFA member, and North Carolina stone shop owner, recommended Joe look into Park Industries®. Joe said, “I knew I wanted American-made equipment so I had easy access to spare parts.” He also wanted a service center that he could call on 24 hours a day. Park Industries® was a perfect fit.

Read their story! Expand the sections below to learn more about their story and partnership with Park Industries®.

Equipment that Lasts & Holds Value

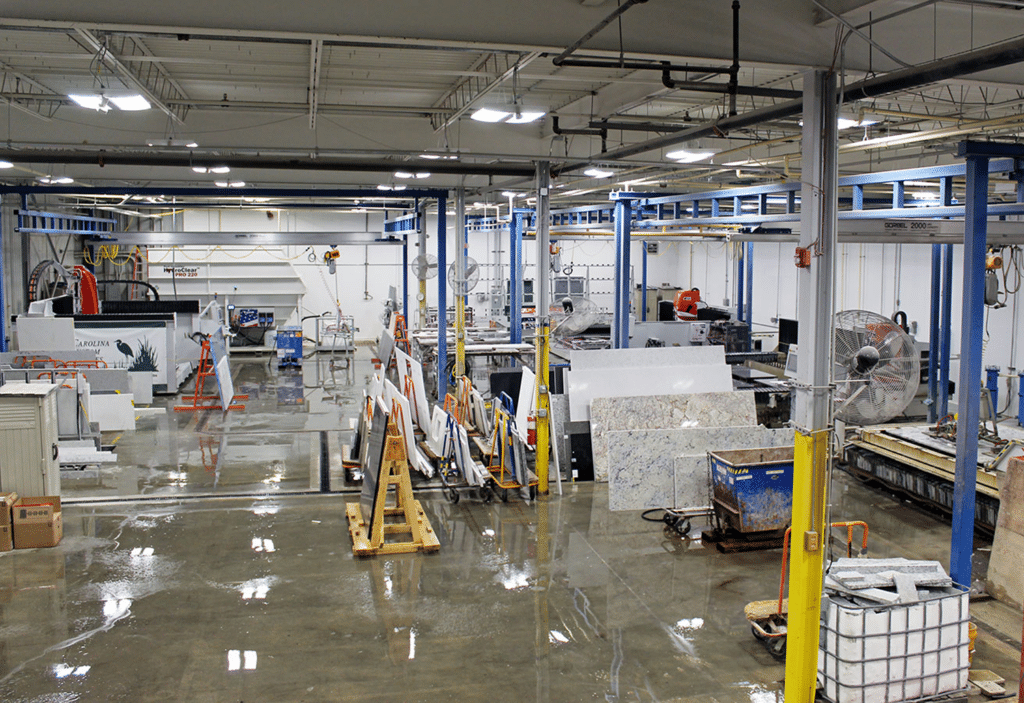

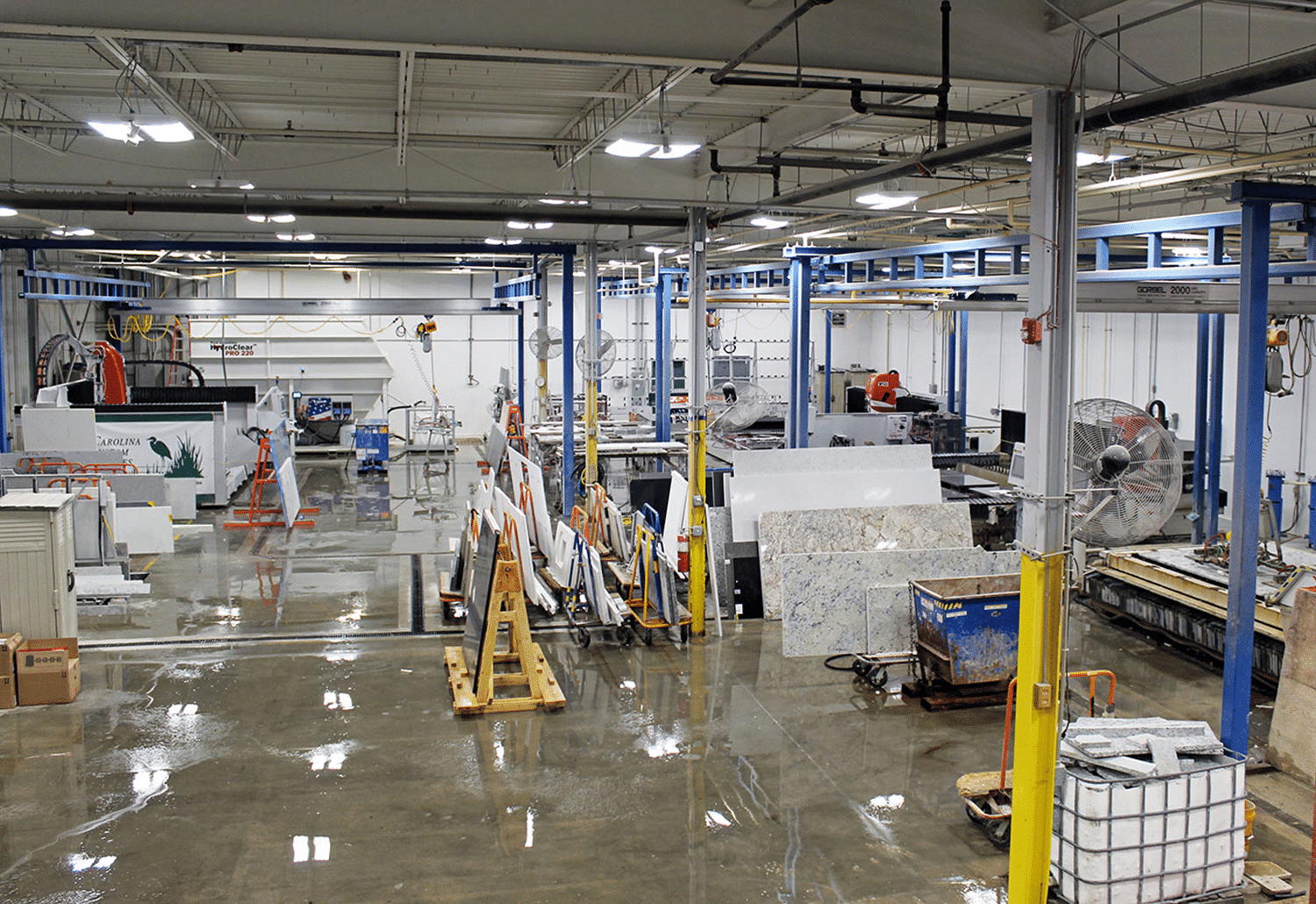

As CCS built their new stone shop, Joe relied on the expertise of Park Industries engineers to help him lay out his new equipment: a YUKON®, Wizard and PRO-EDGE®.

Fast forward 15 years and stone fabrication now comprises 70% of Carolina Custom Surfaces’ business. In late 2020, they sold the YUKON® and Wizard to make room for new digital equipment. “We didn’t get rid of them because they weren’t doing their jobs, we got rid of them because our business changed. Park builds workhorses.”

Joe says that after 15 years, the machines were in just as good of shape as they were on day one. “We maintained them, and had Park come out and service them for us from time to time. As a result, we sold a 2006 YUKON® for half of its original purchase price.”

Going Digital, Then Doubling Down

In 2017, CCS was ready to grow its digital footprint and added the following machines:

- FUSION® CNC Sawjet

- TITAN® 2800 CNC Router

- FASTBACK® Edge Polisher

In 2020 and 2021, to double their capacity and prepare for the latest material trends, they added a:

- TITAN® 3800 CNC Router

- FASTBACK® II with SlabBACK™ Slab Support

- HydroClear™ Pro 220 All-In-One Water System

- SABERjet™ XP 5-Axis CNC Sawjet

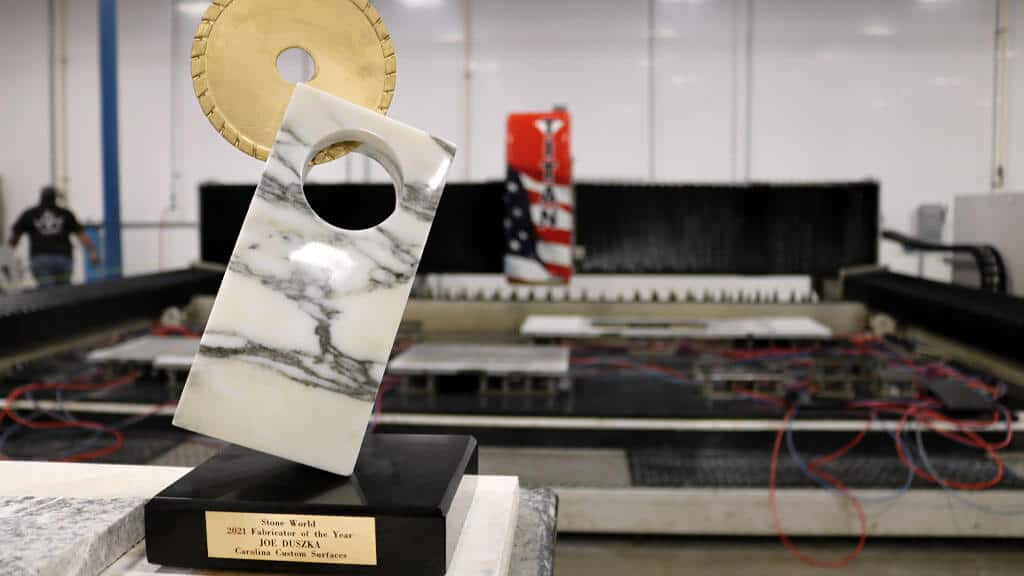

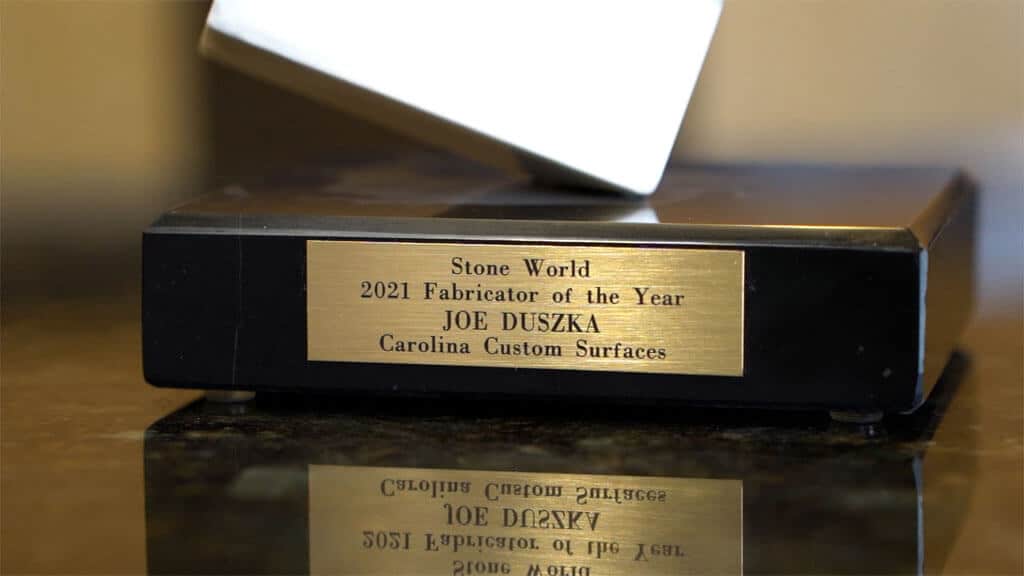

Fabricator of the Year Award

Joe Duszka was named 2021 Fabricator of the Year. Joe has done a remarkable job of sharing information that will help advance the industry and strives for continuous improvement internally.

Joe shares, “Our strongest differentiator is our team. We have a culture that is people-oriented, ethically-driven. Our purpose at CCS is to serve others.” Joe enjoys working with people and helping them achieve their dreams. The great culture paired with innovative machinery has led them to become a leader and win Fabricator of Year.

The sharing manner of the industry helps push every stone fabricator forward. Park Industries has been monumental in providing platforms to increase the sharing of educational information. Joe shares, “The Digital Stoneworking Expos and the Park Business Group have been pivotal, even career-changing.” The education and networking aspect of the industry has been extremely helpful as Joe looks forward to where he would like to take CCS.

Machine Review

SABERjet™ XP

The SABERjet™ XP CNC Sawjet has allowed CCS to continue to stay on the cutting edge of market trends. Joe shares, “The decision to get the SABERjet™ XP was a no-brainer. I really like how well it cuts the trickier materials. We are producing Dekton, porcelain, and various ultra compact surfaces – with improved speed and accuracy.” Three key features Joe credits this to:

- Excellent mitering with both the blade and waterjet

- Smart programming features that help the machine optimize automatically while cutting

- A ballast tank option where the machine cuts underwater for maximum blade cooling

The SABERjet™ XP has made CCS’s entire process smoother. “The SABERjet™ XP is a game-changer! The miters produce quality waterfall edges in porcelain, quartz, and more.”

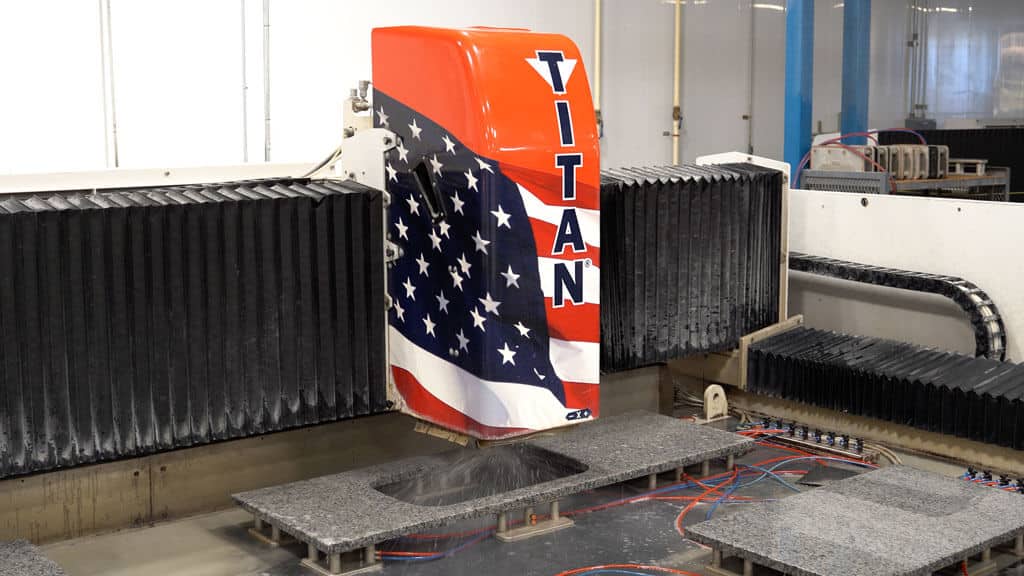

TITAN®

Three TITAN® CNC Routers keep production running at full-tilt and relatively hands-free. Employees load the TITAN® up, hit ‘go’, and walk away. The simple operation makes it easy to train new employees on the TITAN® and the reliability is next to none.

Joe is thrilled with the speed of his two TITAN® 3800s. “It moves so fast. Tool changes, movements between parts, the 3800 is much faster than other CNC’s.”

He continues “The product quality coming off the TITAN® is incredible. The machine is a workhorse, producing high quality edges at a typical rate of 320 inches per minute, but some tools we can run over 400 inches per minute.”

They also purchased the High Speed Water Kit for their TITAN® 2800 so they could run high-speed tooling on both machines.

FASTBACK® II

When asked which of his Park Industries® equipment was his team’s favorite, Joe chuckled. “If I took the FASTBACK® II out of the shop, the guys would kill me.” After the FASTBACK® II Edge Polisher was installed, his team asked, “What took us so long?”

The FASTBACK® II Edge Polisher is simple, fast, and efficient. Joe shares, “The labor savings with the FASTBACK® II is huge. The FASTBACK® II running for 1-2 hours will complete what it takes two qualified polishers to complete in a full day.” The ability to stand up islands and other taller pieces and run them through the FASTBACK® II without people walking them through the machine has made an impact on the shop as well.

Joe is excited about the quality the FASTBACK® II produces. He shares, “The polish is stunning coming off of the FASTBACK® II. It comes off like glass. We match the pieces coming off the FASTBACK® II with the pieces coming off the TITAN® seamlessly.”

HydroClear™ PRO

Water is a major concern for many fabrication shops. Prior to the HydroClear™ PRO, CCS operated with a filter press water treatment. Production reached a level where they had to shut down production to clean the filter 1-2 times each shift.

The HydroClear™ PRO 220 has brought peace of mind to CCS. A few of the impacts the HydroClear™ PRO has made include:

- Machines operate at the highest level of efficiency with minimum maintenance.

- The redundant pump on the back of the HydroClear™ PRO ensures there will be no downtime.

- The chemical feed maintains the water chemistry automatically, so Joe doesn’t have to worry about water testing Bromine or Ph enhancers or decreasers.

CCS uses about 20,000 gallons of water a day through the HydroClear™ PRO. Recycling that water means that they are saving costs on about half a swimming pool’s worth of water a day. Joe elaborates, “The HydroClear™ PRO is one of the best investments we ever made. Once it is turned on, it runs with no problems.”

Why Partner with Park Industries®

True Partnership

In short, Joe Duszka continues to rely on Park Industries® for his equipment because of the relationship he’s built with people in the organization.

“In terms of sales expertise, they take the time to understand my business and what my needs are. ”A few years ago, Joe approached his sales consultant, Matt Zink, with a specific piece of Park Industries® equipment in mind.

The sales consultant looked at Joe’s daily output and told him their volume was too high for the equipment he was interested in. “He told me that I was going to be disappointed if I chose that machine. I appreciated that. He took the time to understand what we were trying to do and provided the best solution for us.”

Skilled Service

Joe shares that Park’s tech support and parts availability is something that truly separates Park: “Lastly, Park’s service is impeccable. There is no one else out there that does the job Park does on the customer service side. If we have a problem, we can call with Park available 24/7 to help us through whatever the issue is. “

He concludes, “Park has top-notch people in all aspects of their business. Park Industries® is not just an equipment manufacturer, they are a solution provider and a true business partner of ours.”

QUICK FACTS

LOCATION

Greensboro, NC, USA

TYPE OF FABRICATION

Countertop

NUMBER OF EMPLOYEES

13 in Fabrication Shop

PARK EQUIPMENT

SABERjet™ XP CNC SawJet, TITAN® CNC Router x 3, FASTBACK® II Edge Polisher, HydroClear PRO Water System, Pathfinder® Digital Slab Station, FUSION® CNC Sawjet (Retired)

PARK PARTNERSHIP

Began in 2006 with a YUKON®, Wizard, and PRO-EDGE®

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.