- Did You Know With Dan

- Programming

- Software Support

In this video we will show you how to use Park and Pause, which can reduce and or eliminate tooling transitions between the Saw Blade and a Router Bit or Water Jet, which will reduce tool marks on your parts. Did you Know?

- Did You Know With Dan

- Programming

- Software Support

Here we’ll show you a few different methods to use Tool Direction. You may find some of the newer methods can reduce clicks. Did You Know?

The operation and maintenance manual for the FOCUS CNC Saw from Park Industries®.

In this video we will discuss reasons and what to look for when your garnet is getting wet and clogging up. Links to Guides Mentioned in Video: Setting Garnet Flow Rate Valve Body Maintenance On-Off Valve Repair

In this video we will discuss how to seat the bullet into the valve body on the waterjet cutting head. Some guides related to the cutting head Waterjet On / Off Valve Repair Waterjet Nozzle Change

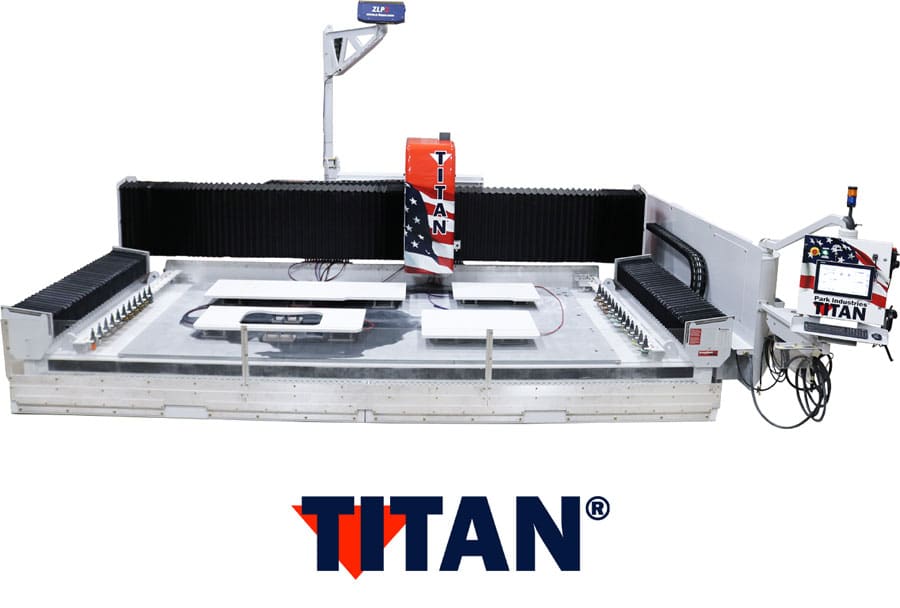

In this video we discuss how to diagnose a 700033 Vacuum Pump Supply Water Flow Too Low alarm on Titan 3K and 4K machines. See our guide on Y Strainer Maintenance for servicing the mesh filter.

In this guide we will go over the test stop function. The test stop is required when powering up the machine & after the machine has been on for 24 hours. Click on Alarm List to see all alarms. Possible Alarm numbers associated with a test stop, or test stop issue: 700144 Machine E-Stop Active […]

In this video we will show you how to set the appropriate garnet flow needed for your waterjet. Mini HOpper Maintenance You can find our guide on mini hopper maintenance here.

In this video, we will discuss how to troubleshoot the vacuum system on your CNC Router. This guide is for Titan 3K and 4 K models, but same process also works with Titan 1K and 2K models. Links to Additional Resources: Vacuum Pump Water Flow Vacuum Troubleshooting Guide

In this video we will give a brief overview of the cutting or inlet water flow on Dynamax Intensifier Pumps and what to look for when getting these alarms. Alarms could be Low Inlet Water Pressure, >40 PSI, 40 PSI If needed we have a booster pump replacement guide.

In this video we will show you how to program your new Hydraulic Controller. You may also want to view our video on how to tune the hydraulic controller.

In this video we will show you how to tune the hydraulic controller on your Pro Edge IV Machine.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.