SlabSmith™

Digital Imaging Software

Slabsmith™ redefines the possibilities when working with natural stone, quartz, and other stone-like products. Slabsmith™ produces digitized slabs that are highly accurate and detailed through proprietary calibration techniques. The digital slabs are true to life in both color and dimension. They contain all of the relevant properties of the original slab that was photographed. The digital slabs are inventoried and are used to create 3D visual layouts for customers.

The SlabSmith™ Process

1 – Creating Digital Slabs

Everything depends on the digital slab – It’s easy to be misled into thinking of the creation of a digital slab as nothing more than making a pretty picture. In reality, nothing could be further from the truth. The biggest difference between a nice picture of a slab, and a Slabsmith™ digital slab is accuracy. Slabsmith’s Slab Maker™ module, paired with the Park Industries Pathfinder Photo Station uses proprietary calibration technology that ensures that the digital slabs that it creates are accurate in every important detail.

Dimensional accuracy – When a Slabsmith™ photo station is calibrated using Slabsmith’s calibration routines, the resulting digital slab is accurate dimensionally to a millimeter or less. This accuracy goes beyond just the length and width of the slab; in fact, any random point on the slab is correct. Virtually all distortions that result from the camera position, or lens aberrations are eliminated.

Digital slab properties – Along with the accuracies mentioned above, each digital slab includes a complete record of all its important properties. This includes common things like the material name, lot number, thickness, and inventory ID, but can be extended to include any information that might be valuable to your business when maintained with the digital slab.

Color accuracy – Slabsmith™ assures that the color of the slab is accurate and consistent from slab to slab. Even small variations in color can be seen during the layout process when properly calibrated. Slabsmith’s color reproduction allows you to see the subtlest of color variations at seams even when used with ‘uniform colored’ quartz products!

2 – Inventory

Save & manage your digital slabs – When a digital slab is created it is immediately saved into Slabsmith’s SQL database. This provides the ability for anyone in your company to easily locate and view the slabs in your inventory based on any of the properties of the slab. You can even search for remnants of a particular size rectangle or even a particular size ’L’ shape.

Slabs can be put on hold, assigned to a job, organized by color, price, etc. It’s all up to you and it’s fully customizable. Slabs are never deleted from the inventory, but instead are “Consumed” in jobs. This means you also get a historical record of every slab that comes through your facility.

This historical record also allows you the potential of ‘mining’ your own slab data to search for trends that will help you make better business decisions.

3 – Layouts

Create, save & manage layouts – It’s hard to overstate the benefits Slabsmith provides as a direct result of being able to easily and accurately visually layout a job on digital slabs.

Sales – Slabsmith allows you to provide an understanding and comfort level to your customers that has previously not been possible. With Slabsmith you get a true “What you see, is what you get” experience, one that you know you can deliver every time.

Slabsmith’s layout tools will allow you to easily optimize for beauty or for yield. In other words, it’s both a sales tool and a cost saving tool. And since Slabsmith also manages your remnants, you will be able to utilize it to reduce your scrap yard instead of simply cutting full slabs for every job just to avoid searching for remnants.

4 – Optimization & Yield

Reduce scrap! – The Perfect Match™ layout module provides tools that are customized for the specific things you need to do to efficiently layout countertops. There are tools for the following functions:

- Line up edges a saw blade apart

- Rotate randomly or to fixed angles

- Group counters

- Nestle two odd shapes together as close as possible

- Many more

In the end you can lay out a countertop on your slabs with less effort and time with Slabsmith than anything else available.

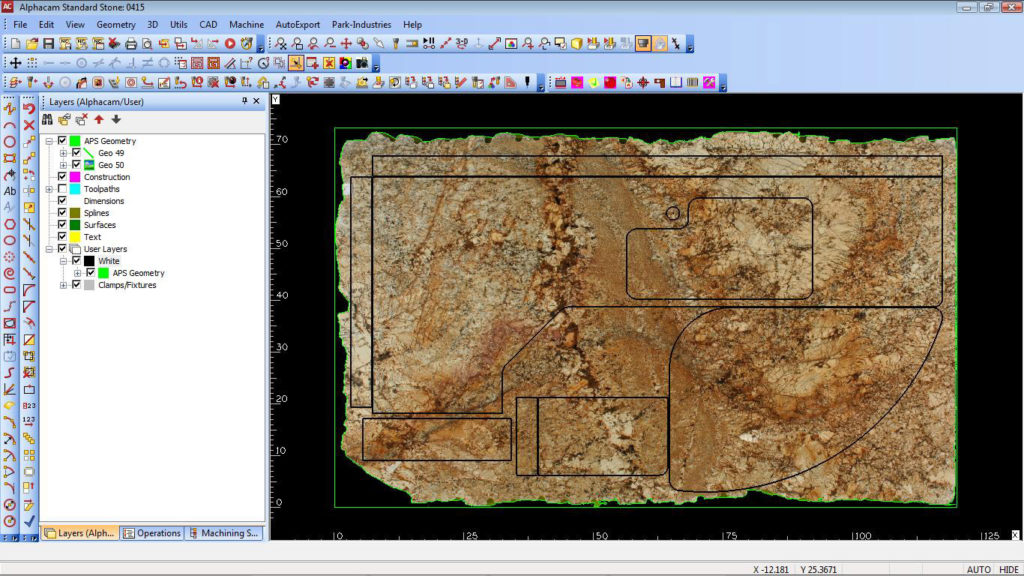

5 – Fabrication

Time to cut it up – After completing your desired layout, Slabsmith exports to your current CNC equipment for immediate programming of your saw or sawjet. Cut it, fabricate it, and install it. One trip to the customer with guaranteed results. The digital life is the good life.

6 – Maintenance

The secondary benefits – Have you ever had a customer call about a counter that broke a year after you installed it? Not a problem. Slabsmith’s database maintains a complete history of every layout you have ever installed. Just open the layout, select a few likely slabs or remnants from your current inventory, drag the broken counter onto the new slabs and move it around until it looks good.