TXS-3000 Whisper

ThinStone Veneer Saw

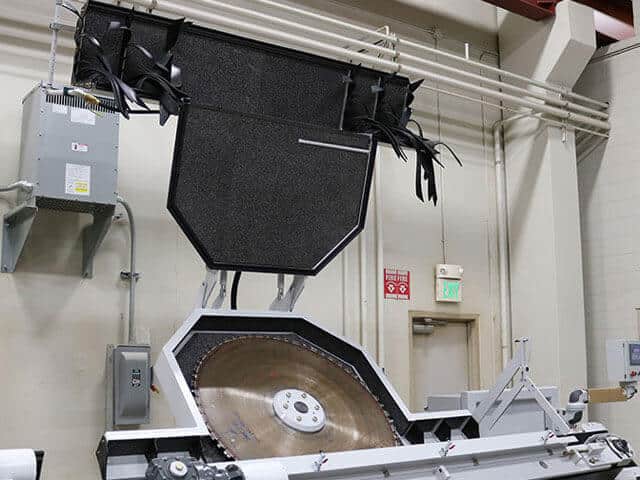

Packed with innovative features, the ThinStone® TXS-3000 Whisper will bring your thinstone productivity to a new level of production. Patented V-belt technology, sound dampening and noise containment system, and simple touchscreen control are only a few of the revolutionary features of the ThinStone® TXS-3000 Whisper.

Flats & Corners

CuttingSOUND

DAMPENINGStone & Brick

Veneer

Choose your Region

Please choose your region and fabrication type below.

Watch Videos

Key Features

- Quick, Simple, Profitable

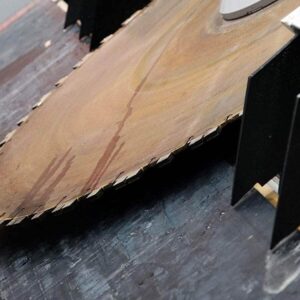

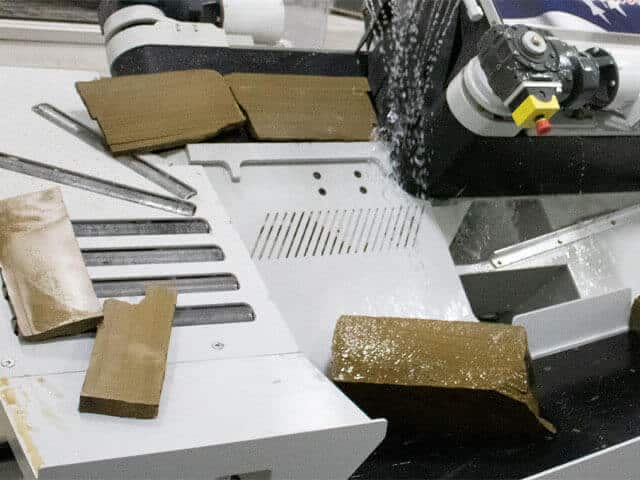

Our patented ThinStone® TXS-3000 Whisper veneer saw makes cutting thinstone veneer flats and 90-degree corners quick, simple, and profitable. The unique v-structured cutting surface easily cuts split-face or natural finished sandstone, brick, limestone, and other hard stones.

- Revolutionary Design

A solid foundation that’s built to last:

- Patented Design

- Stone Separator Conveyor

- Belt Coordinated Amp Control

- Vulcanized Belts

- Armor Shield Protection

- Power Packed

Optimal efficiency and employee safety focused:

- 50 hp Motor

- Arbor Motor Soft Start

- Arbor VFD (Optional)

- Whisper Sound Dampening System

- Wash-Down Duty Electric Motors

- Safety Guarding

- Ergonomic Design

- Operational Flexibility

Designed to meet your fabrication needs:

- Spray Bar Washing

- Thickness Adjustments: 1/2″ minimum to 2 1/2″ maximum

- Manual Height Adjustments

- Flexible Machine Configuration: Right or Left hand

- Hinged Blade Guarding

- Water Forks for easy blade changes

- Simple Controls

Intuitive, simple operation:

- Interactive Visual Controls with touchscreen

- Simple to Set Controls

- Troubleshooting Tips

- Hour Meter informational tool

- Simple On/Off, Pause, Start/Stop button controls

- Conveniently located Water Shut-Off Valve

Specifications

| Select up to 3 models to compare key specs | TXS-3000 WhisperView Layout Drawing | |

|---|---|---|

| Cut Types | Flats + Corners | |

| Arbor Motor | 50 hp | |

| Blade Size | 48" | |

| Max Cut Depth | 16" | |

| Cutting Speed | Up to 120" per minute | |

| Amp Control | Auto | |

| VFD | Yes | |

| RPM's | 250-1,050 | |

| Sound Dampening System | Yes | |

| Stone Separator Conveyor | Yes | |

| Material Type | Brick, Stone (Sandstone, Limestone, and More Natural Hard Stones) | |

| Footprint including clearance (L x W x H) | 23’.5” x 16’7.125” x 11’8” (with shroud open) | |

| Weight | 9,800 lbs. |

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.

The ThinStone TXS-3000 Whisper is the best I have seen in a long time. Would love to have a shop full of them. Very easy to make adjustments and repairs and simple to operate.

Yes, I recommend this product.

The ThinStone TXS machine is unbelievable. It will be a while before we get our crew up to the capability of the machine. I love the unbreakable-ness of it, and I love all the support.

Yes, I recommend this product.