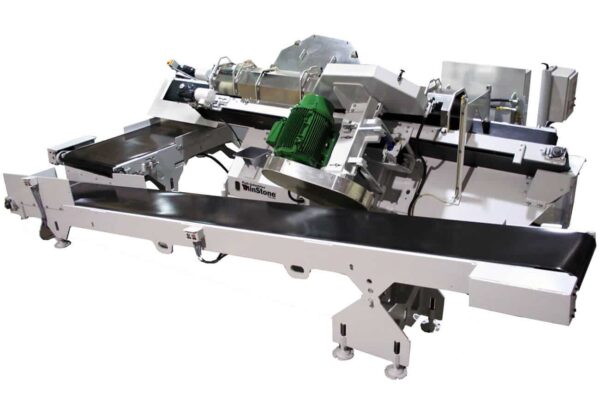

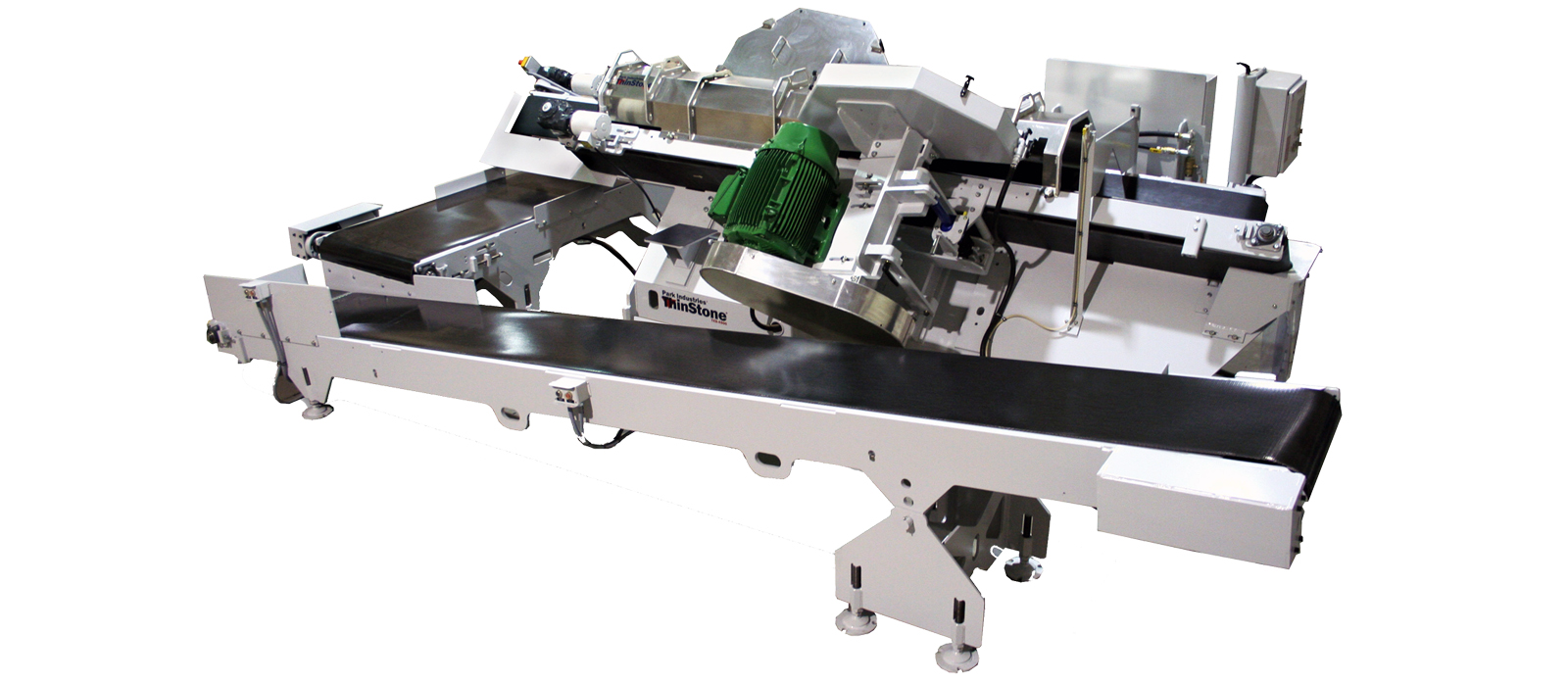

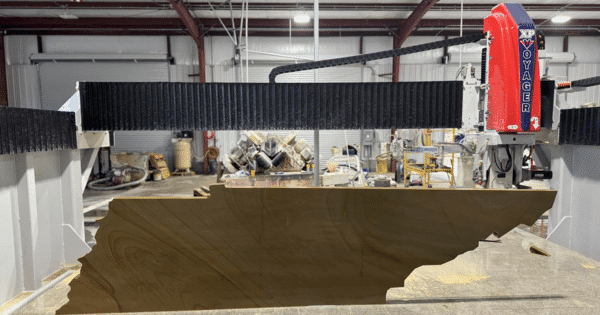

TXS-4000 Series

ThinStone Veneer Saw

Our patented ThinStone® TXS-4000 series veneer saws make cutting thinstone veneer flats and 90-degree corners quick, simple, and profitable. The unique v-structured cutting surface easily cuts split-face or natural finished sandstone, brick, limestone, and other hard stones up to 16” high and 2.5” thick.

Flats & Corners

CuttingDual Arbor

MotorsStone & Brick

Veneer

Choose your Region

Please choose your region and fabrication type below.

Watch Videos

Key Features

- Engineered to keep up with your workflow.

Operating a TXS-4000 series saw is effortless. Simply adjust the vertical blade position, then place the stone or brick on the durable belt conveyor. Automatically adjust the belt speed to 10 FPM with the rugged touchscreen control unit. Another feature is the Belt Coordinated Amp Control (BCA) which automatically places production in a cruise-control mode, reducing wear and tear on the blade.

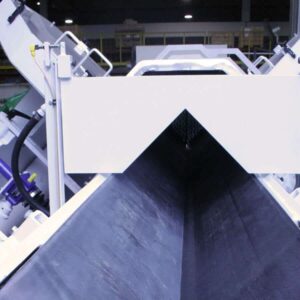

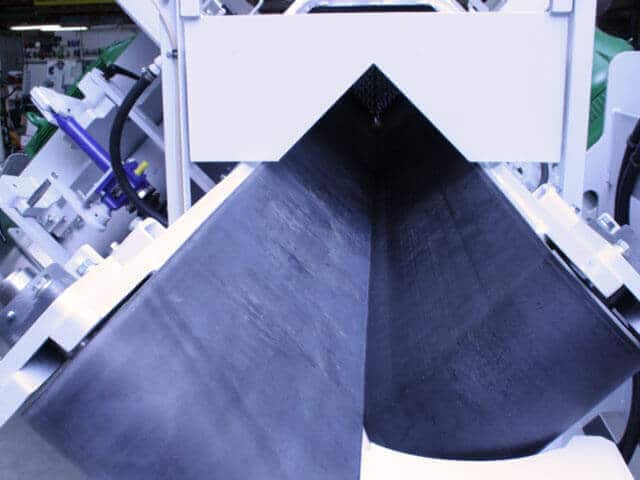

- Cut corners while cutting corners (without sacrificing quality).

Reduce production time and expenses while increasing productivity and profitability with the TXS-4000 series saw. Choose from two different configurations to meet your fabrication needs.

- Eliminate Waste. Increase Profits.

When your reputation is on the line, you need a saw that cuts consistently every time. That’s why a TXS-4000 series saw uses perpendicular blades and automatically controlled conveyor speeds to accurately cut flat and corner pieces to uniform sizes. Eliminate waste and increase profits with consistent cuts time after time.

Specifications

| Select up to 3 models to compare key specs | TXS-4500View Layout Drawing | |

|---|---|---|

| Cut Types | Flats + Corners | |

| Blade Size | Two 40" (Both blades used at once) | |

| Max Cut Depth | 12" | |

| Arbor Motor | Two 40 hp (50 hp optional) | |

| Cutting Speed | Up to 120" per minute | |

| Amp Control | Auto | |

| VFD | NA | |

| RPM's | 250-1,050 | |

| Sound Dampening System | No | |

| Stone Separator Conveyor | No | |

| Material Type | Brick, Stone (Sandstone, Limestone, and More Natural Hard Stones) | |

| Footprint including clearance (L x W x H) | 26’7.25” x 18’7.5” x 6' | |

| Weight | 15,500 lbs. |

The TXS ThinStone has allowed us to take on many opportunities!

Yes, I recommend this product.

First and foremost our new TXS-4500 Single Arbor machine paid for itself in under two months. Secondly, if it was not for the TXS-4500 we would not have been able to meet our customer’s needs. Finally, the total experience in dealing with Park Industries has been refreshing and first class.

Yes, I recommend this product.