Prevent Unplanned Downtime

Right Tool. Right Resources. Right Time.

TAKE CONTROL OF YOUR MACHINE’s MAINTENANCE.

Planned Downtime

Planned Downtime is necessary to complete the preventive maintenance steps needed to prolong the life of your machine and ensure your production is at top efficiency. When planned properly, maintenance work can be done during off-peak hours and in a controlled environment where resources, like people and parts, are readily available.

Unplanned Downtime

Unplanned Downtime is the nemesis of maintenance organizations. These incidents create major disruptions and chaos, resulting in profit losses. Unplanned downtime occurs when a machine fails without warning – perhaps due to a lack of preventive maintenance or a faulty part. Elimination of unplanned downtime should be a high priority.

How to Prevent Unplanned Downtime Emergencies

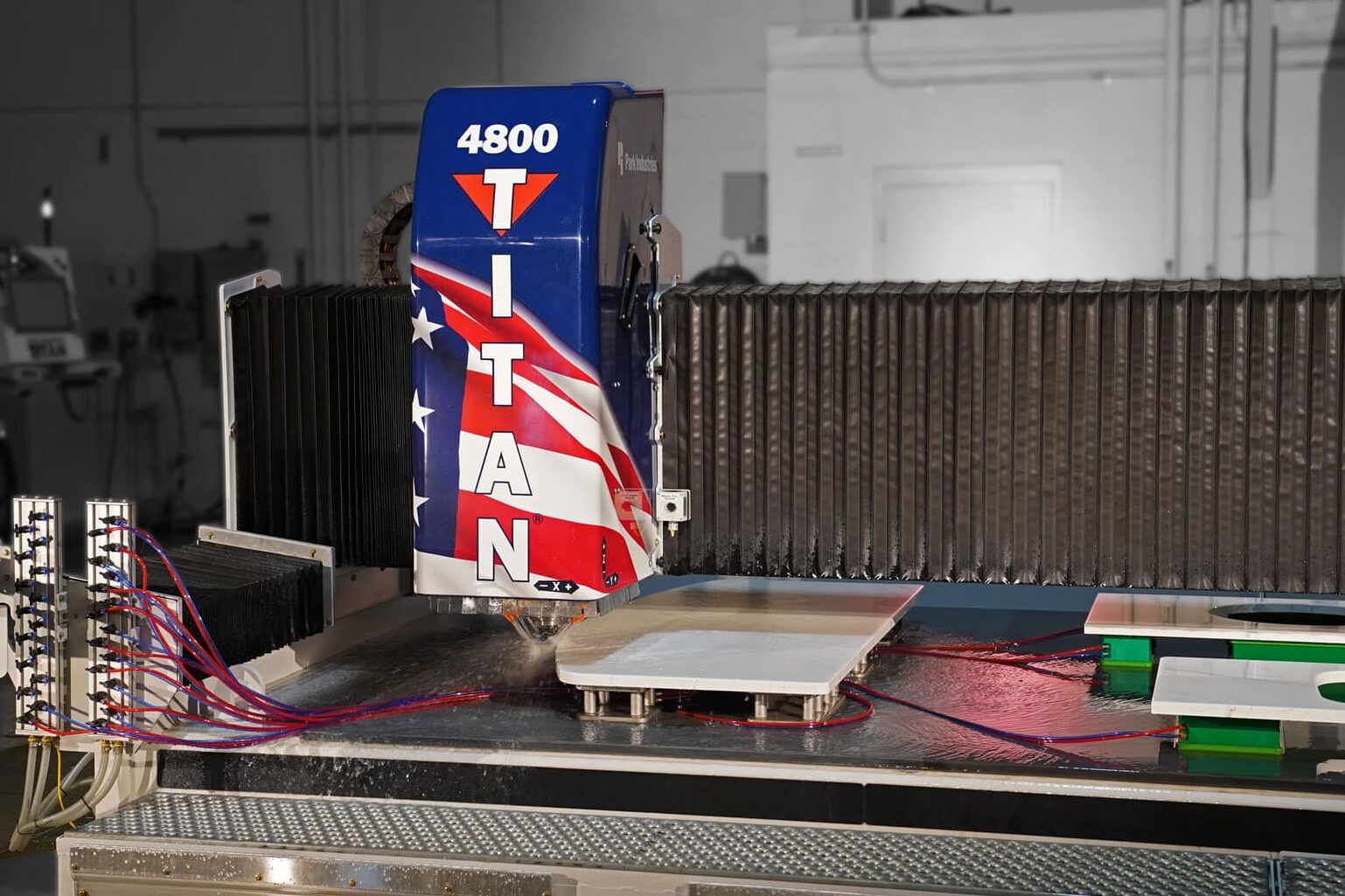

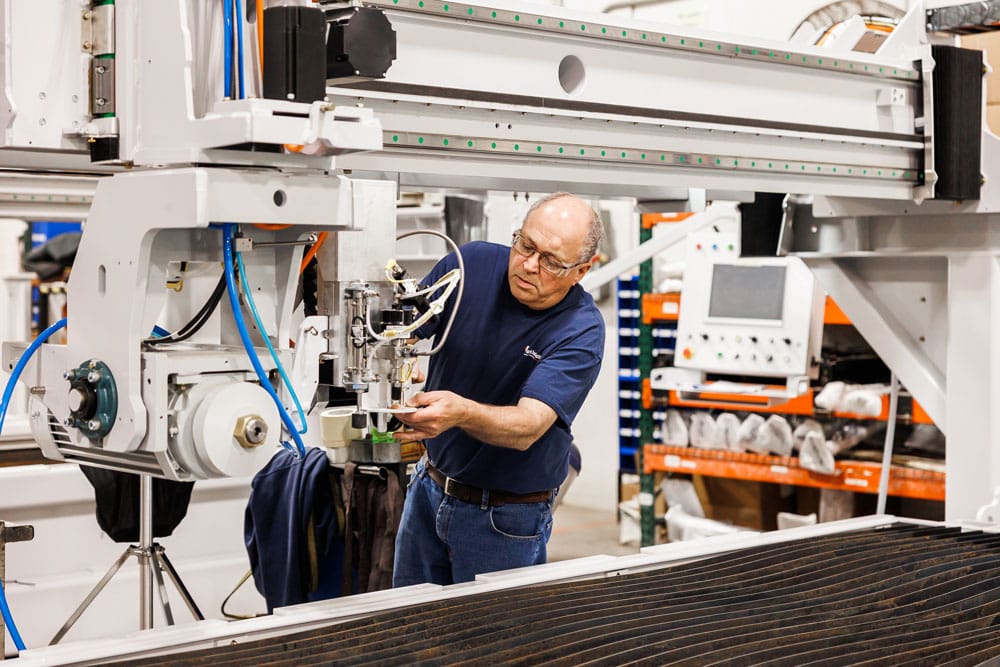

Purchasing a preventive maintenance program can dramatically extend the life of your machine, providing you with industry-leading support from certified Park Service Technicians to keep your machines in top working order. Park offers two unique services designed to fit your needs.

Health Check Inspection (HCI)

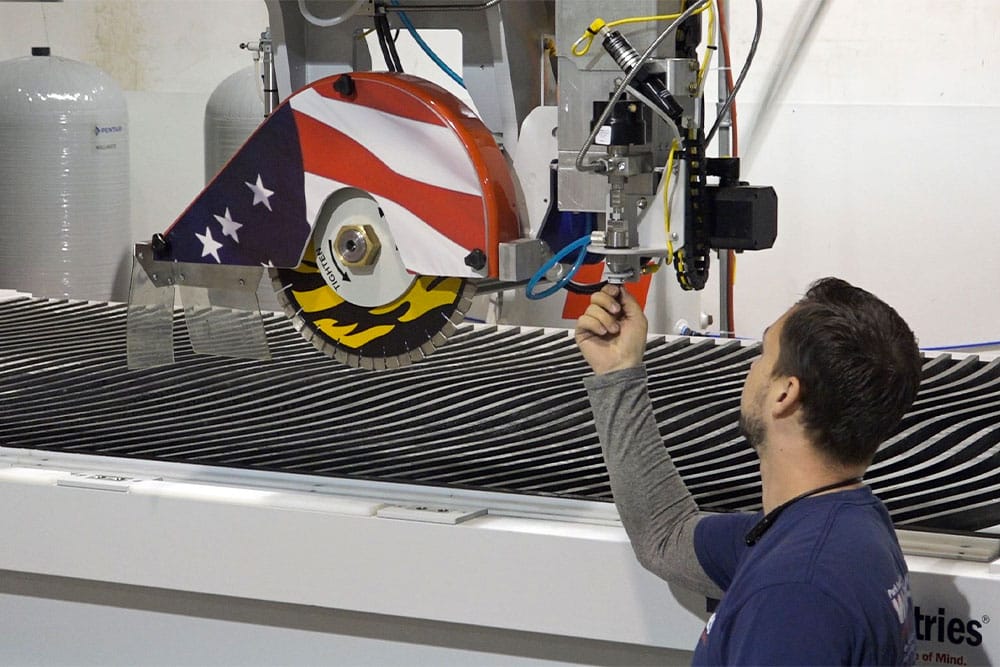

- Onsite checks scheduled will, on average, take five hours per machine. Onsite machine inspections are scheduled in advance and may take up to five hours per machine

- Machine(s) will be carefully assessed for early detection of possible failures from regular machine wear or incorrect settings.

- The mechanics, pneumatics, and electronics of your machine(s) will be inspected using the machine(s) checklist and specifications.

- When the inspection is completed, you will receive a written report of basic settings, wear status, and functional and safety characteristics. This report may also include recommendations for replacement parts and additional service work needs.

- A return, onsite visit may need to be scheduled should you need additional help/time correcting the failures that were not corrected during the HCI visit.

Preventive Maintenance (PM)

- Onsite checks scheduled will take, on average, 10 hours per machine. Onsite machine preventative maintenance

- Health Check Inspection (as outlined above) will be completed.

- All fluids and filters will be changed per machine guidelines.

- Pending time availability and parts onhand, machine(s) will be dialed and calibrated.

- When the inspection is completed, you will receive a written report of basic settings, wear status, and functional and safety characteristics. This report may also include recommendations for replacement parts and additional service needs.

- A return, onsite visit may need to be scheduled should you need additional help/time correcting the projected failures.

Onsite, Repair Visit

Sometimes, things just don’t go as planned. If your machine is in a downtime state that requires an onsite technician, rest assured that Park has an entire team of certified Field Service Technicians ready and available to be dispatched to your location.

Advanced Maintenance Clinics

Park Industries hosts exclusive Advanced Maintenance Clinics for the countertop industry geared toward machine operators who will learn maintenance techniques, improve machine life, and reduce downtime.

The Value of Having the Right Tools, The Right Resources, at the Right Time.

- Early Detection of Potential Issues

- Reduced Unplanned Downtime

- Maximum Machine Uptime

- YOU Take Control of When Your Machines are Down = Planned Downtime

- Avoid Emergency Downtime Costs (Expediated Shipping Costs, Field Service Costs, etc.)

Contact SERVICE

For urgent or immediate service, please call our 24/7 customer service at 800-785-3391.

Otherwise, please use this form to request service, field service, parts, or ask us a question. Our fast, friendly team of service technicians are here for you and your machine.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.