While the TITAN® CNC Router is well-known for its high-production polishing and shaping capabilities, its offers fabricators additional custom capabilities like leathering.

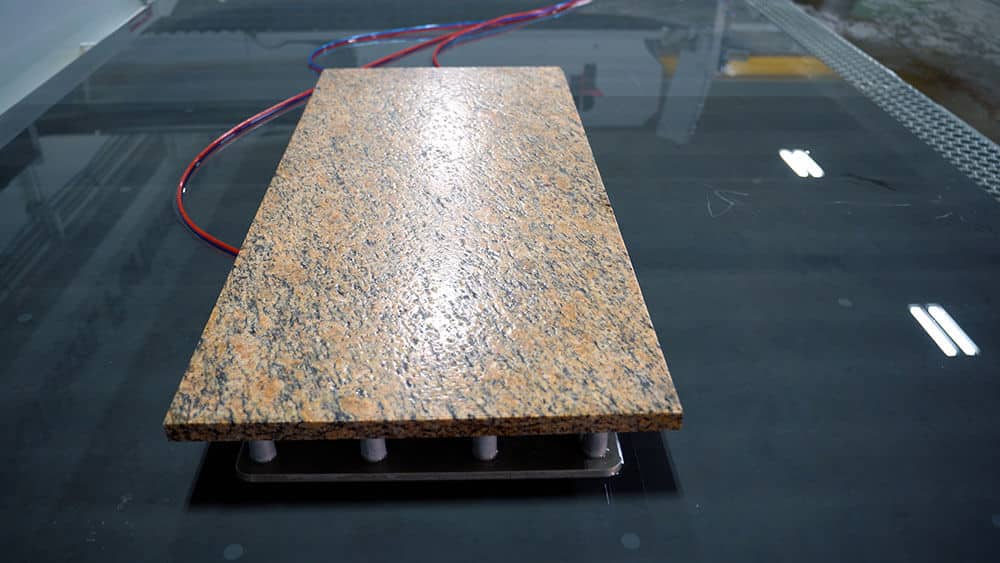

Leathering is a finishing process that enhances the natural beauty of stone by adding texture and depth to the surface of the material. This technique not only improves the visual appeal but also enhances slip resistance and durability. Park Industries® partnered with Blick Industries for a new 11.25″ Leatherhead with Frankfurt style brushes to get leathering work done faster. This leatherhead works well with both TITAN 3000 and 4000 Models.

Fabricators interested in the TITAN CNC Router or the 11.25″ Blick Leatherhead for their TITAN can contact Park Industries for more information.

Watch the TITAN CNC Router Leathering

About the TITAN CNC Router

The TITAN® CNC Router is renowned for its high production capabilities and reliability. It features a workspace of 8’ x 16’, for handling multiple materials, large islands, and full slabs. Additionally, ArmorDeck’s long-term performance surpasses that of traditional aluminum, tables maintaining its integrity without requiring frequent maintenance. Whether it’s leathering, sloping drain boards, or creating shower pans, the TITAN excels in delivering exceptional results.

Want to see more of the TITAN in action? Watch Park Industries experts guide you through sloping & leathering processes for a shower base, showcasing the versatility of the TITAN CNC Router.