Now is the perfect time to upgrade your DESTINY to a TITAN. Reallocate the money you are investing on your DESTINY™ to a new TITAN® 4000 CNC Router from Park Industries®.

Explore below six great reasons to upgrade your CNC, the business value it provides you, and a case study on Duncan Stone, who is experiencing game-changing results after finally upgrading their DESTINY to a new TITAN CNC Router.

reasons to upgrade Your Countertop Fabrication CNC:

- Lower cost of ownership.

- Lower labor costs due to increased productivity.

- Increased production capability and capacity.

- Electrical component and software updates.

- Quantum™ Belt Driven spindle is easy to maintain and replace parts and comes with a 5-year limited warranty.

- Section 179 Tax Deduction allows you to deduct up to $1,16K from your gross income if you purchase equipment.

Understand the Business Value

| TITAN® 4000 Series | DESTINY™ Series | |

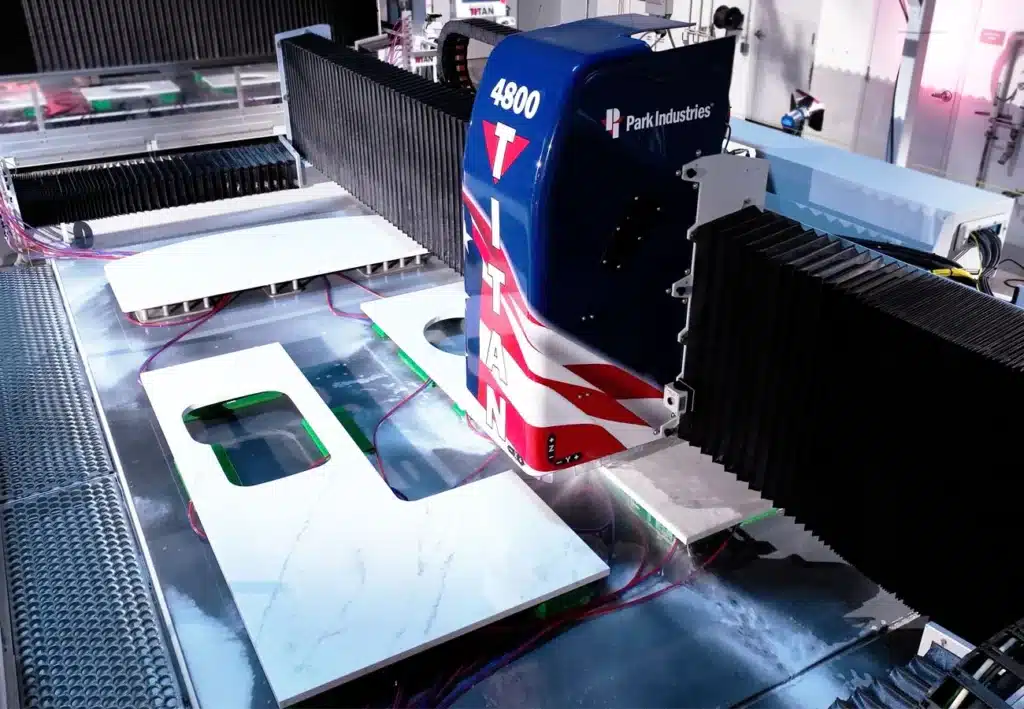

| Productivity | Ability to Run High Speed Tooling Due to High Water Flow Rates. Rapid Speeds of 2,600 IPM. | Unable to Accommodate High Speed Tooling. |

| Component Availability | Most Recent and Advanced Components on the Market. | Critical Components are at End of Life or Unavailable Placing Your Business at Risk. |

| Spindle | Quantum™ Belt Drive Spindle is Easy to Repair in the Field, Including Draw Bar Replacement. 5-Year Limited Warranty. | Omlat Spindle Needs to be Sent In for Repair. |

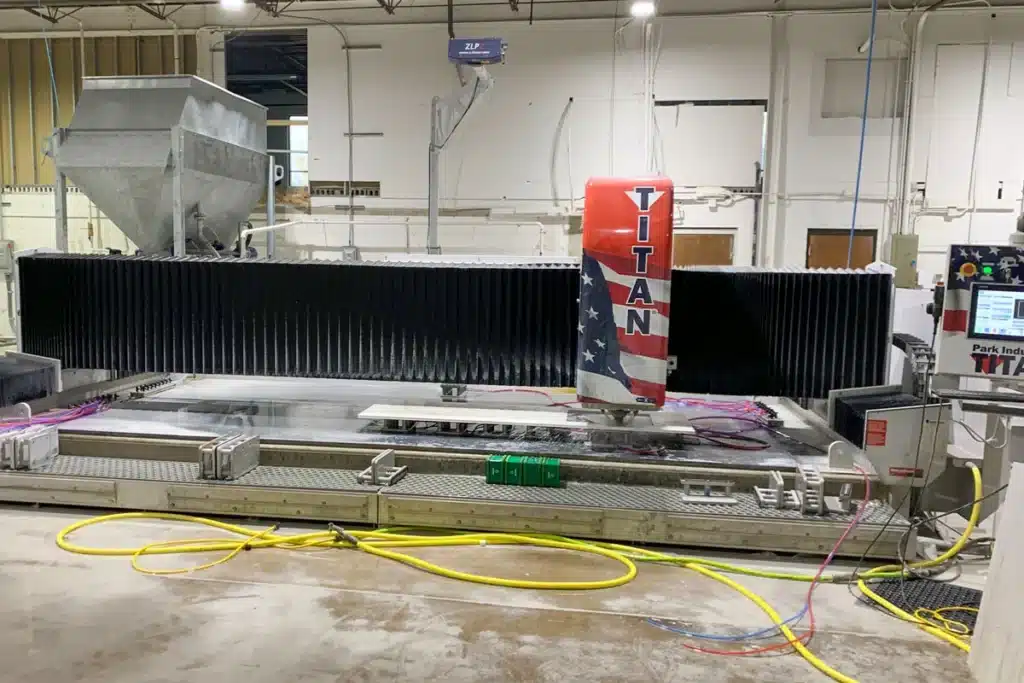

| Table Size | TITAN® 4700 = 115 sq ft (Process approximately 12 Vanity Tops) TITAN® 4800 = 128 sq ft (Process approximately 14 Vanity Tops) | Small: 24 sq ft (Process 4 Vanity Tops) Large: 35 sq ft (Process 6 Vanity Tops) |

| Tool Capacity | TITAN® 4700 = 36 Tool Pockets TITAN® 4800 = 68 Tool Pockets | 25 Tool Pockets |

| Tool Management System | Ability to Easily Upload Tool Data from Offline Tooling Systems. Integrated Tool Management System is Optional. | No Integrated Tool Management System. Manually Input Tooling Data. |

| Multi-Lingual Controls | English & Spanish languages with easy, intuitive navigation and operation at the touch of a button. | English |

| Windows OS | Current Windows 10 Platform | Windows 7 or Older and No Longer Supported by Microsoft. |

Case Study: Duncan Stone decides it’s time for a CNC upgrade.

DESTINY retired and TITAN CNC Router installed.

Duncan Stone opened their shop in 2016 and in 2017 purchased a used DESTINY CNC ROUTER. For over 6 years, Duncan Stone ran their DESTINY, and in 2023 they decided it was time for an upgrade. “Our DESTINY had seen a lot of use, it was getting outdated, and we knew it was time for an upgrade,” comments Steve Duncan Jr., “So, we decided to purchase a TITAN and it has been transformational.”

“The speed of the TITAN is immensely faster than the DESTINY and we are getting nearly 250-300% more work done with a TITAN,” continues Steve. When asked how they produce so much more, Steve commented, “In addition to the efficiency of programming, the laser helps us position the material and one person can position the material with the vacuum cup floats which would take 2 -3 people at the DESTINY, saving us time and labor.”

When asked why they purchased a TITAN, Steve reflected, “Park has been building CNC routers for a long time. I grew up running a Park PRESTIGE, then DESTINY, and now the TITAN. Every new generation of machines from Park seems to make not just minor tweaks, but leaps in fabrication technology, and the TITAN is no exception. We are very happy with the choices we have made with partnering with Park Industries.”

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.