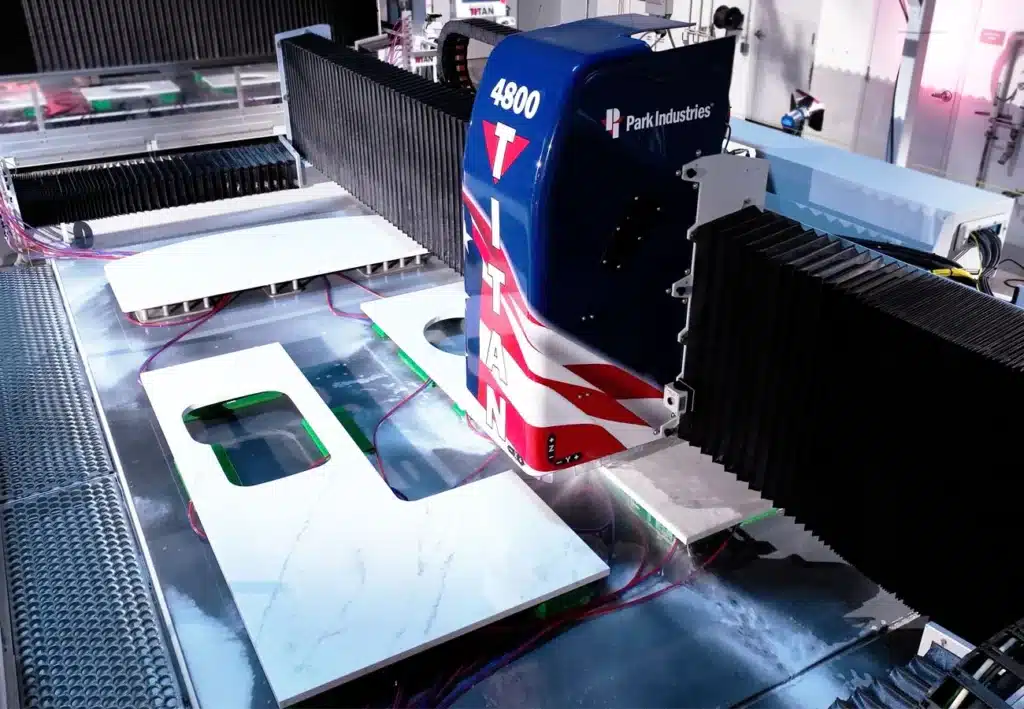

Now is the perfect time to upgrade your TITAN® 1000 Series to a TITAN 4000 Series. Reallocate the money you are investing on your TITAN to a new TITAN 4000 CNC Router from Park Industries®.

Explore below six great reasons to upgrade your CNC and the business value it provides you.

reasons to upgrade Your Countertop Fabrication CNC:

- Lower cost of ownership.

- Lower labor costs due to increased productivity with high-speed tooling optimization.

- Increased production capability and capacity.

- Easiest-to-use software & control updates.

- Quantum™ Belt Driven spindle is easy to maintain and replace parts and comes with a 5-year limited warranty.

- Section 179 Tax Deduction allows you to deduct up to $1,16K from your gross income if you purchase equipment.

Understand the Business Value

| TITAN® 4000 Series | TITAN® 1000 Series | |

| Productivity | Ability to run high speed tooling due to high water flow rates. Rapid Speeds of 2,600 IPM (x & y); 650 IPM (z) | Ability to run high speed tooling (need to add adapted water flow kit). Rapid Speeds of 2,360 IPM; 500 IPM (z) |

| Component Availability | Most recent and advanced components on the market. Readily available inventory. | Critical components are at end of life or unavailable placing your business at risk. |

| Spindle | Quantum™ Belt Drive Spindle is easy to repair in the field, including draw bar replacement. 5-Year Limited Warranty. | Omlat elecrospindle needs to be send in for repair. Expired Warranty. |

| Table Size | TITAN® 4700 = 115 sq ft (Process approximately 12 Vanity Tops) TITAN® 4800 = 128 sq ft (Process approximately 14 Vanity Tops) | TITAN® 1600 = 104 sq. ft. (Process approximately 10 vanity tops) TITAN® 1700 = 106 sq. ft. (Process approximately 10 vanity tops) TITAN® 1800 = 127 sq. ft. (Process approximately 14 vanity tops) |

| Tool Capacity | TITAN® 4700 = 36 Tool Pockets TITAN® 4800 = 68 Tool Pockets | TITAN® 1600 = 34 tool pockets TITAN® 1700 = 36 tool pockets TITAN® 1800 = 62 tool pockets (Subtract 2 with itm) |

| Tool Management System | Ability to easily upload tool data from offline tooling systems. Integrated tool management system is optional. Quick-scan tool technology – easier tooling swapping. | Manually input tooling data. Integrated tool management systems (itm) is optional. |

| Vacuum Pump | 3 HP standard with 5 HP option | 3 HP standard |

| Multi-Lingual Controls | English & Spanish languages with easy, intuitive navigation and operation at the touch of a button. | English |

| Windows OS | Current Windows 10 Platform | Windows XP |

| Maintenance | Quick change water union (3-minute change) Automated greasing system System diagnostics dashboard On-board interactive maintenance scheduling Easier to schedule maintenance and improved notifications | Water union (upwards of 40-minute change) Manual greasing |

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.