Making the leap to your first CNC stone machine can feel like a big step. And it is. But with the right preparation and training, adding CNC technology to your shop is one of the smartest decisions you can make for productivity, precision, and consistency.

At Park Industries®, we’ve helped thousands of fabricators transition to CNC automation. If you’re considering your first machine, here are the key areas to understand.

Digital Templating & Slab Imaging

Accurate measurements are the cornerstone of any successful stone fabrication. Digital templating is strongly recommended, producing DXF files that integrate directly into your programming software, eliminating the inconsistencies of manual templates and speeding up the process.

A digital slab imaging solution, like the SlabVision™ Slab Scanner , and its powerful layout software will provide you with a high resolution digital slab image. It also helps with veinmatching, program layout, and more. Alternatively, cameras at the saw are also available, like the SIDE-SHOT™.

Programming

Programming is often perceived as complex, but with the right tools and training, it becomes straightforward. Software like Alphacam, combined with Park Industries’ custom Park EZ™ Buttons, streamlines the process. Our comprehensive training covers everything from tool selection to material definition, ensuring you can generate accurate cut paths efficiently.

While the software handles much of the heavy lifting, it’s important to understand how material types, tooling options, and part geometry influence your program. This knowledge helps avoid errors and improve efficiency. Park’s machine training is designed to walk you through these details, so you’re confidently controlling the entire process.

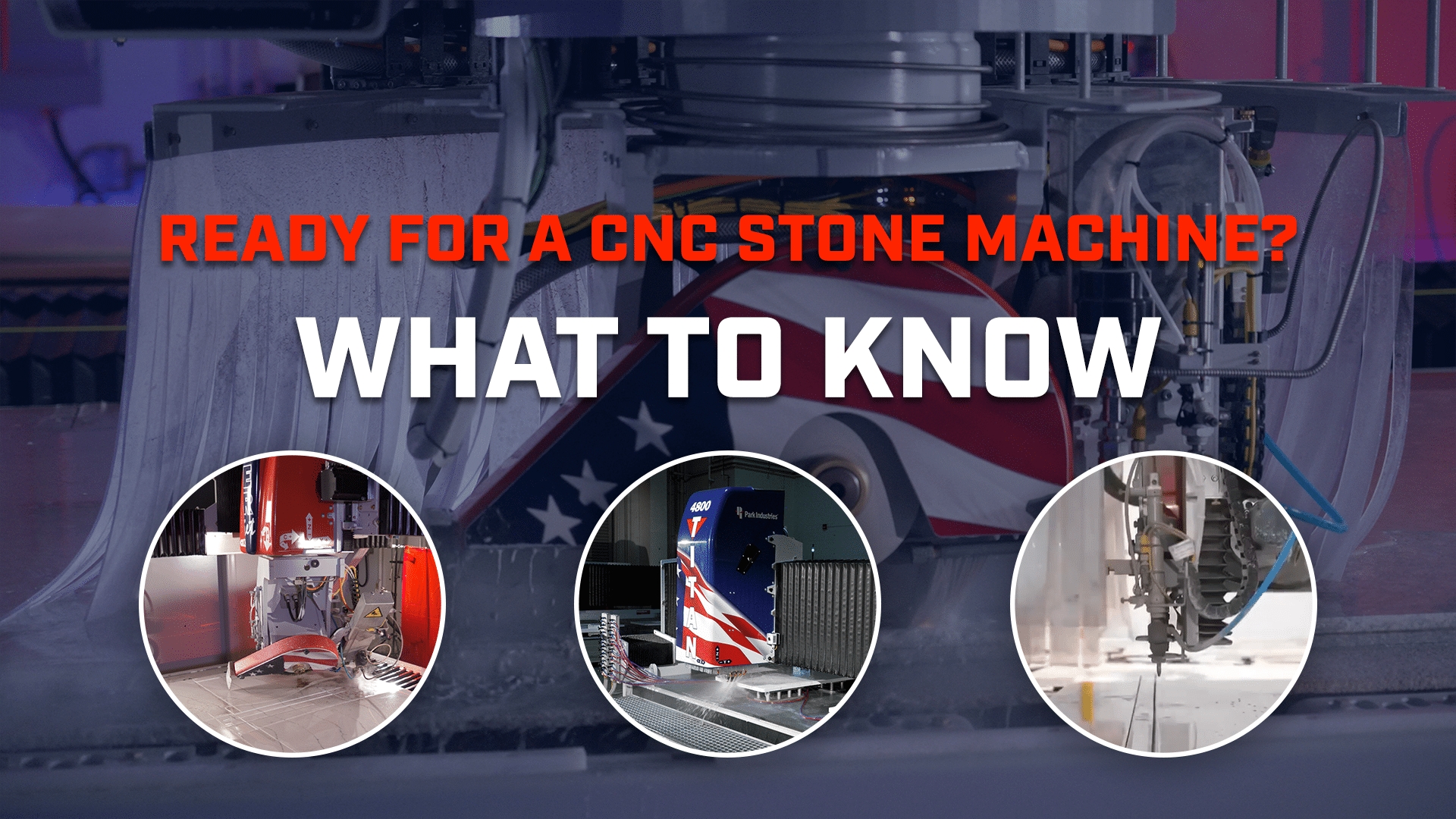

Cutting

CNC sawing is typically the first step fabricators take in automating their shop. Cutting digitally is faster, offers higher material yield, and far more accurate, especially with mitering. Operating your CNC Saw or Sawjet becomes a seamless process once the program is ready. It’s as simple as load the slab, scan the program, and hit go.

Similar cutting rules apply to say a bridge saw – set your blade up, make sure your table is in good condition, etc. CNC sawing however, makes it easier to ensure accurate cutting, with features like automatic tool measurement, automatic material height sensors, EZ blade calibration, a blade library to store tooling info, and more.

For shops ready to upgrade their cutting capabilities, the VOYAGER™ XP CNC Saw offers powerful, 5-axis cutting with TightCut™ technology for material efficiency. For more efficiency and waterjet capabilities, the JAVELIN™ CNC Sawjet or SABERjet XP CNC Sawjet combine a powerful blade cutting with a precision waterjet, allowing for maximum material yield and faster production.

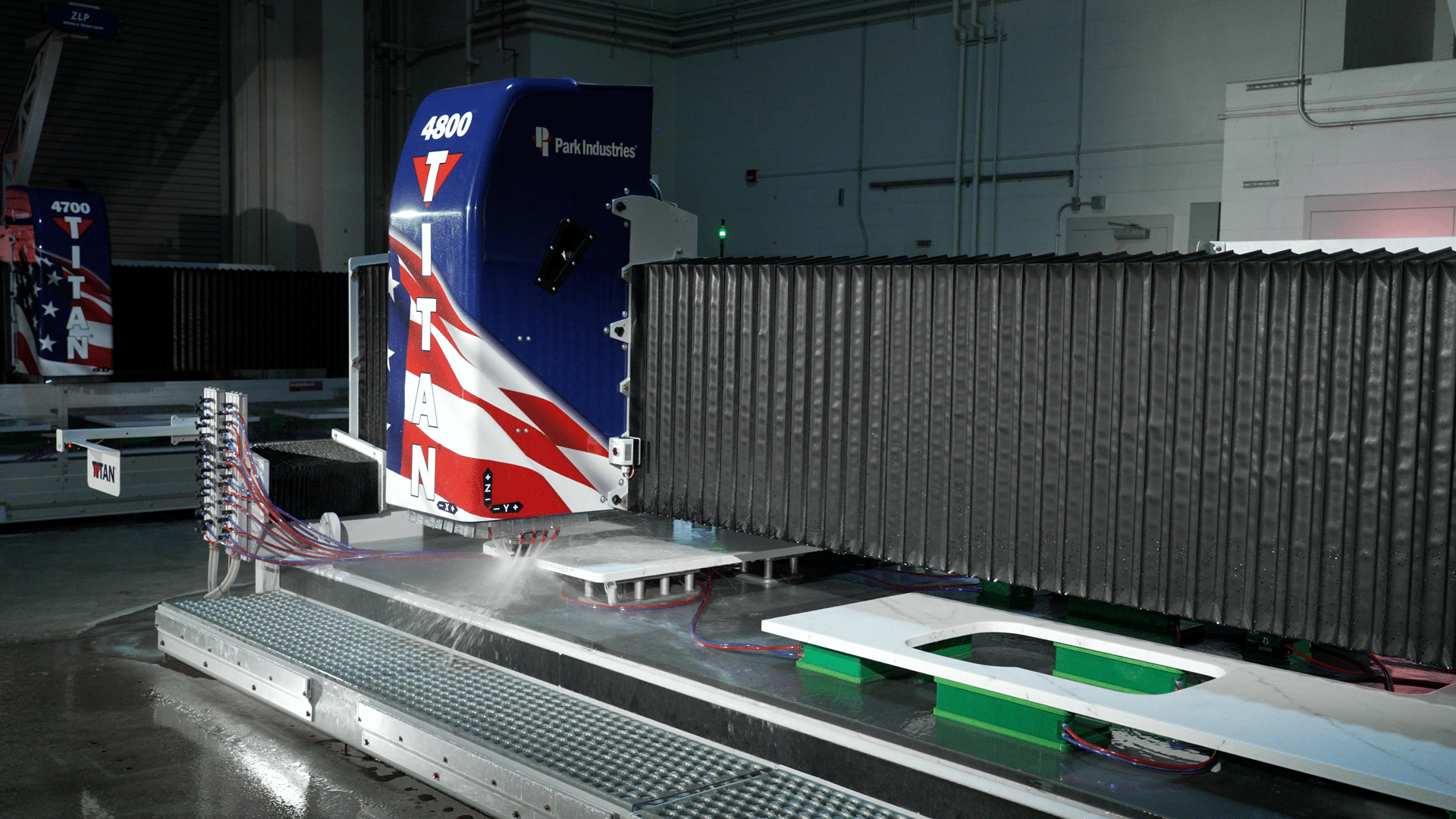

Polishing

A CNC router can be a game-changer for shops polishing by hand. It can drop sinks, shape/polish any edge, and even additional capabilities like leathering, sloping, or fluting. Operating a CNC Router involves setup like placing vacuum pods, loading the parts, and managing tooling. Once parts are loaded, it is a simple as scan the program sheet, hit go, and walk away as the machine works.

The TITAN® CNC Router series offers unmatched efficiency, uptime, and production with a powerful combination of speed, accuracy, and operational ease. Operators quickly gain confidence, producing high-quality results with minimal manual intervention.

Team Mindset

Transitioning to CNC technology requires a shift in mindset. It’s not just about new machines, it’s about adopting a new approach to fabrication. CNC automation is designed to make your team’s work more efficient and less labor-intensive.

Park supports this transition with training for operators, owners, and managers, ensuring your entire team is aligned and confident.

Want to see how others have embraced CNC in their shops? Check out Fabricator Spotlights.

Implementation

The initial month with a CNC machine focuses on learning and building confidence. Park Industries® offers in-shop training, on-site programming guidance, and virtual resources to support your team. We also provide dedicated install coordinators and handle the full machine installation process, so you’re set up correctly from day one with minimal stress on your team.

Our commitment doesn’t end after installation. We’re here to assist every step of the way. For a detailed look at what to expect, explore our First Month with a Stone CNC Machine Guide.

Ready to Take the Next Step?

Adding your first CNC machine is a major investment, but with the right preparation and support, it becomes a smooth and rewarding transition.

Park Industries® offers a full library of Buying Resources to help you choose the right CNC machine, understand your shop’s needs, and feel confident in your investment. Explore the resources or contact us with any questions.