A-One Solid Surfacing boosted production 4X with Park Industries® machines, cutting kitchen turnaround from three days to less than half a day.

A-ONE SOLID SURFACING

Founded in 1995 by Bill Campbell, A-One Solid Surfacing operated with manual methods for decades. Today, his son Dawson leads the company as it evolves into a highly capable custom fabrication shop, producing four times the volume they achieved with manual processes.

Quick Facts

LOCATION

West Valley, UT, USA

TYPE OF FABRICATION

Custom Residential & Commercial

PARK EQUIPMENT

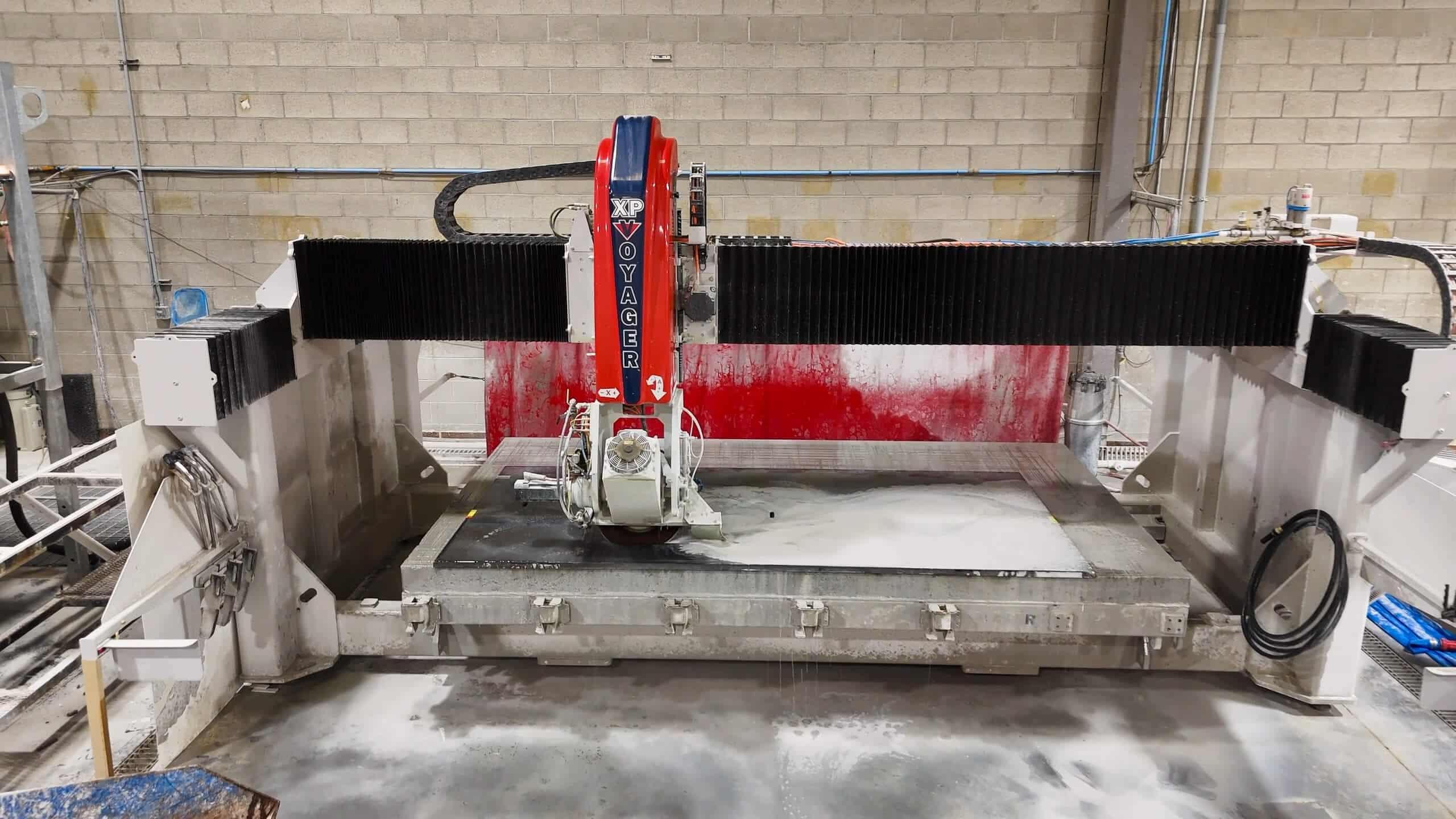

VOYAGER™ XP CNC Saw

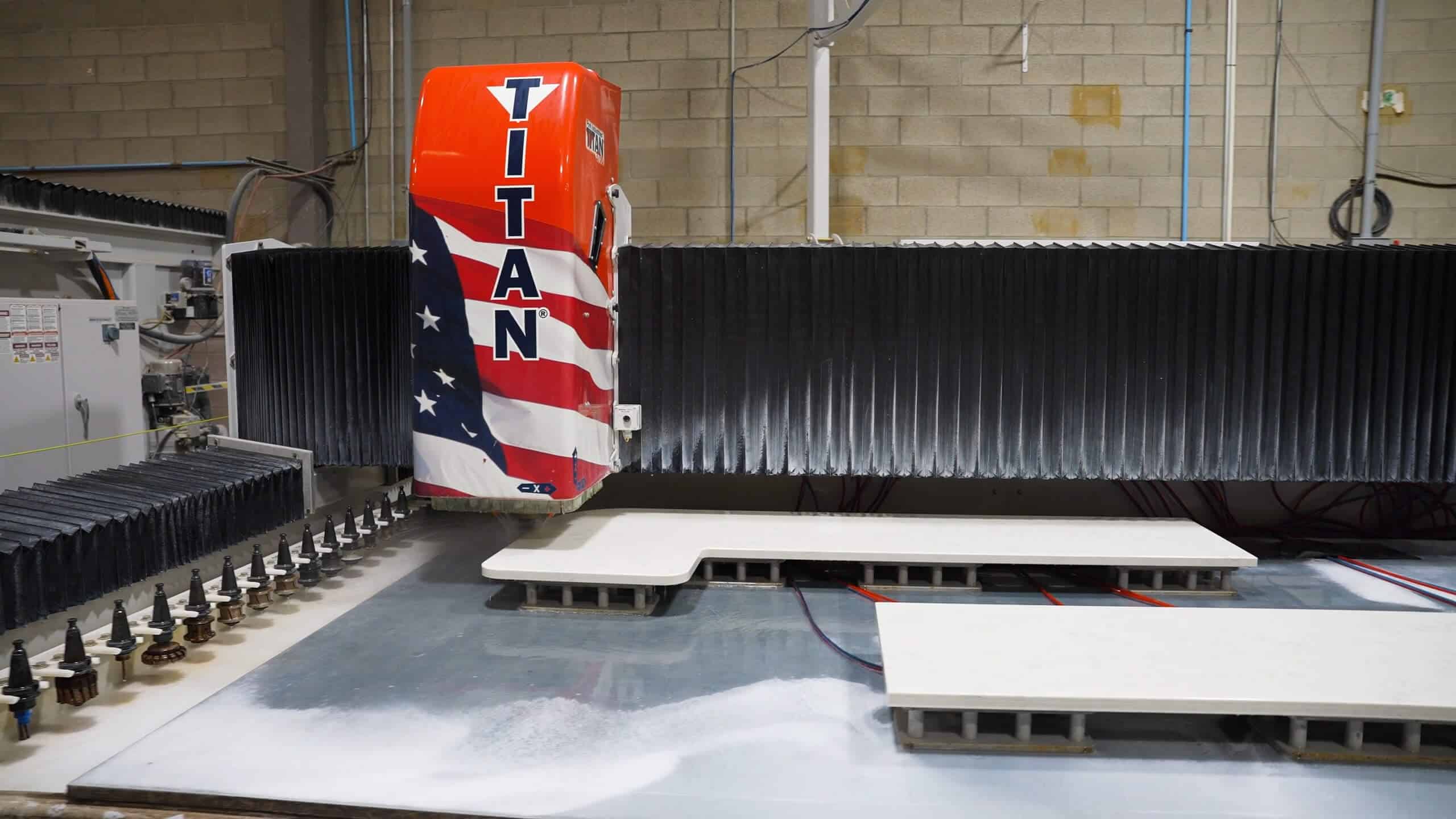

TITAN® CNC Router

FASTBACK® II Edge Polisher

HydroClear™ PRO Water System

Pathfinder® Digital Imaging

PARK PARTNERSHIP

Started with a YUKON® II Bridge Saw

Taking Off with the VOYAGER XP

When A-One Solid Surfacing looked to modernize, the VOYAGER XP CNC Saw quickly became a centerpiece.

“The VOYAGER XP fills all our needs and then some. We had been producing around 50 square feet a day before it, now we’re hitting 200 square feet a day with it. It’s been a gamechanger.”

The VOYAGER XP allows the team to nest pieces tighter, cut more efficiently, and fully leverage their slabs. “Being able to turn that power into usable cutting features is where I see the biggest advantage,” Dawson explains.

Reliable Precision from the TITAN

For finishing, the TITAN CNC Router brought a new level of consistency and capacity.

“The TITAN, it’s been amazing,” Dawson says. “You’re able to do 10X what you used to be able to do in terms of capability and not relying on a guy that might be there or not be there. You’re able to do it with peace of mind. The ease of use is amazing. The quality is amazing.”

High profitability with the FASTBACK II

Flat edge work is dominated by the FASTBACK II Edge Polisher, which Dawson calls a must-have for any shop.

“Every shop needs a FASTBACK II,” he says. “It’s the fastest ROI you’re going to get in your shop, whether you’re running digital or a bridge saw. The FASTBACK II speeds all of your fabrication up because you can send it through, you’re going to be at the other side, you’re going to pull it off, and you’re going to say, wow, this is the best polish I’ve ever seen.”

Smarter Water Use with the HYDROCLEAR PRO

A-One Solid Surfacing relies on their HydroClear PRO Water System to provide a clean, recycled water supply for their fabrication process. This helps them save money and fabricate responsibly.

Even when the unexpected happens, the HydroClear PRO keeps production moving. “A year ago, our water was down for the whole building,” Dawson recalls. “We were able to use the HydroClear, still run our hand polishers off of recycled water, and run the saw. That one or two days that we had our water turned off, we were still producing.”

Production Growth and Excitement for the Future

With their full lineup of Park machines, A-One Solid Surfacing has seen incredible growth.

“We are now at 4X production of what we were three years ago, doing everything manually,” Dawson says. “A standard 60 square foot kitchen, we used to produce in three days. Now it’s a day, less than half a day. Having the machines in the shop definitely gets you excited for the future. It gets you excited for the scale and the growth you can see in your company.”

For Dawson’s father, who started the business nearly 30 years ago, the transformation is remarkable. “My dad, he walks in and he’s like, wow, I would have never envisioned I had a shop like this.”

A True Partnership with Park Industries®

The partnership with Park goes beyond equipment. Service and support have been a defining factor in A-One Solid Surfacing’s success.

“Park’s commitment to service was a big selling feature for us,” Dawson says. “I always had somebody that could pick up and answer my question, jump on my computer, walk me through the process. We were always stuck on Park Industries®. There really was no other choice for our shop here.”

He adds, “The customer service, the Made in America, that’s a big thing for me. They take pride in their quality. When you bring your first client into the shop, somebody that you’re really looking to land, a big partner, they’re going to be wowed by your whole process.”