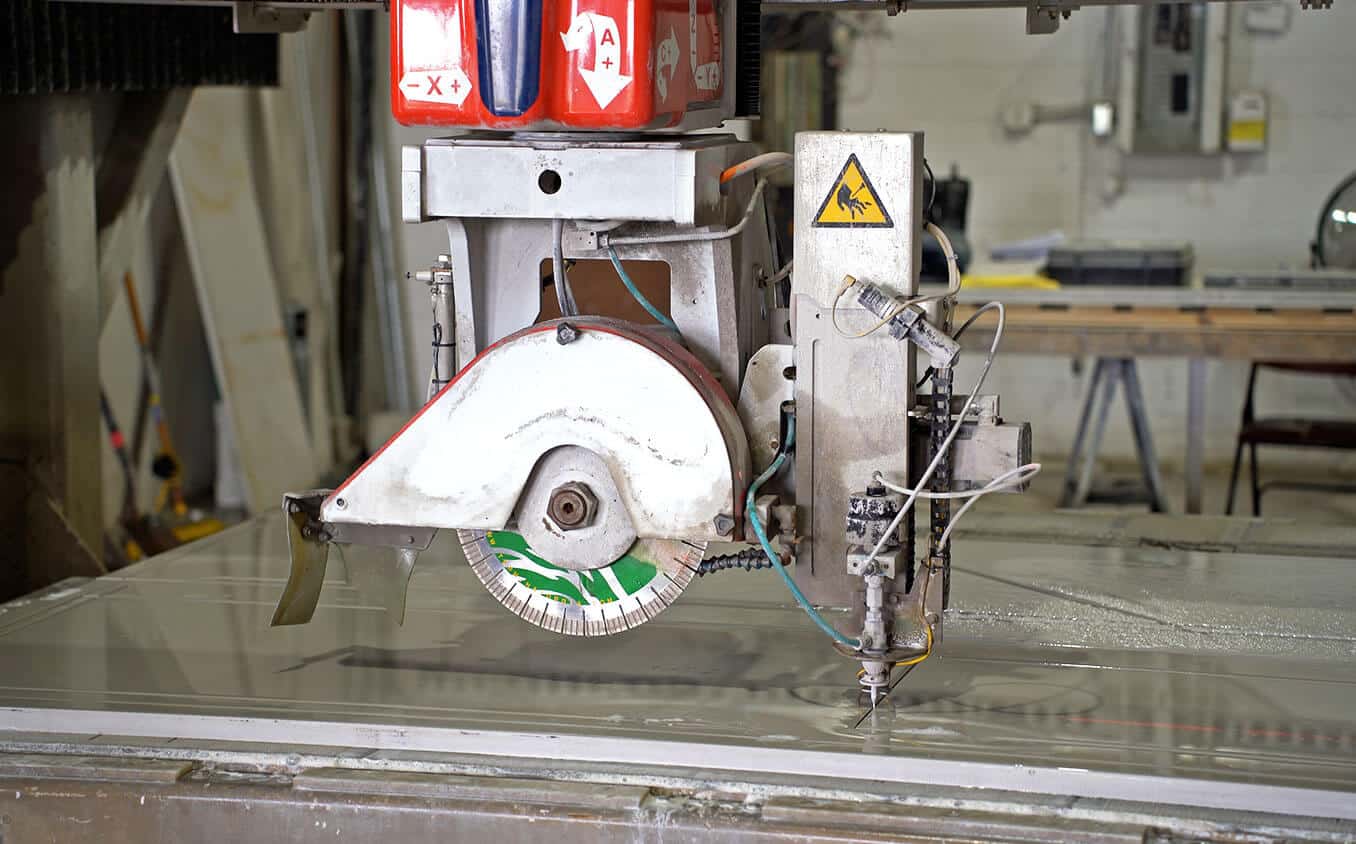

Founded in 2014, Duncan Stone is a family business ran by a father and two sons in Minnesota. In 2021, they purchased a SABERjet™ XP CNC Sawjet to help speed up their production and waste less of the slabs they were cutting.

The outcome since adding the sawjet? Expanding growth and thousands of of slabs cut.

Maximum Material Yield

Making their material go further is one of the best results Steven Duncan Jr. (shop manager) has seen since adding the SABERjet™ XP. “Every granite shop knows any stone going into the dumpster is wasted money,” he says. “With the SABERjet™ XP cuts there are no overcuts like with a manual saw and we can now actually use the remnants we create in a job.” By adding the industry’s leading sawjet, Duncan Stone reduced their slab waste from about 20% down to 2% per slab.

Time saved and utilized elsewhere was the next best outcome of the SABERjet™ XP. Two key areas of improvement for Duncan Stone: Miter cutting and milling sinks and faucet holes.

On their bridge saw, they would have to babysit cutting – especially miters. Now it’s as simple as one-two-three. Enter an angle, press ‘go’, walk away, and come back to a clean edge.

The waterjet’s efficiency with sinks has also eliminated the need for milling out holes on their CNC, saving 60% of the time previously spent on this step.

Know Exactly What You Get with Park

Steve Jr. entered the fabrication world right out of school in 2003, training at a shop that exclusively ran Park Industries® machines. After getting a feel for the high-quality machines, service, and people at Park, he knew undoubtedly this was the partnership Duncan Stone needed. “It’s invaluable knowing I can call Park literally 24/7 and someone will be there to guide me, and in the worst-case scenario I can get new parts within one day if something does come up.”

Not only are Park Industries® machines American made, but they’re Minnesota manufactured. This is a huge bonus to Duncan Stone who is also located in Minnesota, a quick 40-miles up the highway.

Be Happy. Get the SABERjet XP.

When asked what he’d tell someone interested in improving their cutting production, Steve shared: “The SABERjet™ XP is a beast. We’ve cut over 2,500 slabs since we got it, averaging 10 a day and that’s not even its full capacity.” His summary is even simpler: “You will only be happy with it.“

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.