Company Integrates New Machine Into Processes

Increases Efficiencies Two-Fold

Since 2007 Park Industries® has been evolving the FUSION CNC Saw/Waterjet product line within the countertop market. “We saw an opportunity to transform how architectural stone was being processed by introducing the FUSION line to architectural customers,” comments Park Industries Product Manager.

In March of 2016 Park Industries installed their first FUSION CNC Saw/Waterjet intended for architectural stone at Sonny and Sons, located in the heart of New York. Sean Odell, Sonny and Sons’ FUSION operator comments on the value of this new machine to their operations, “This machine has made my life so much easier. I don’t need to reposition or relocate pieces to be cut which has allowed me to do multiple jobs at once.”

Once the FUSION is programmed, the stone is positioned on the table utilizing a zero/zero reference. The operator simply positions the material, scans a bar code to call up the program, and the machine begins its work. It’s that simple.

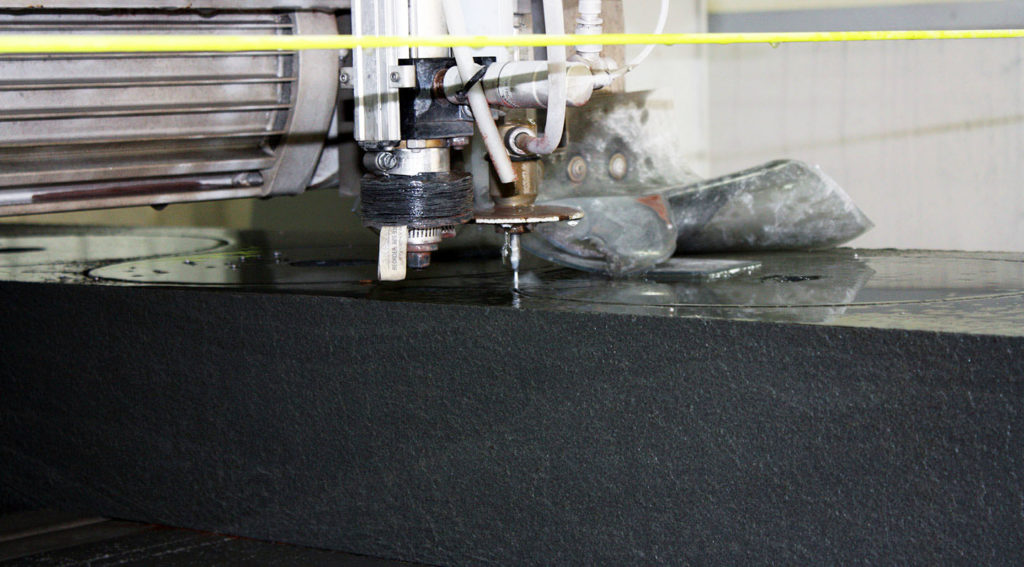

The FUSION’s dynamic CNC duo of saw and waterjet results in faster cuts, higher production and lower labor costs, and greater uptime. One sawing head does double duty. The saw makes fast, straight cuts and the waterjet cuts complex curves with precision. The 18 inch blade has a cut depth of up to 4 inches and the waterjet can pierce and cut up to 8 inches of stone. The FUSION Arch also utilizes the common line cutting strategy and greatly reduces fabrication time and increases stone yield by over 10%.

“The combination of having one machine that utilizes both a CNC saw and waterjet has transformed our company,” comments Harry Triebe, Sonny and Sons owner. “We are now capable of bidding opportunities that we once turned away because we didn’t have the capability or it was too labor extensive. What use to take us days to process now takes us just a few hours – unattended – to process. And it has reduced our lead time dramatically.”

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.