Natural Stone Design began in 1988 specializing in creating high-end, custom work.Since Mike & Teri Medina took over the company in 2013, Natural Stone Design has tripled in volume. Mike largely attributes this to the additions of the SABER™ CNC Saw and the TITAN® CNC Router.

Natural Stone Design Fabrication

Mike Medina, Owner of Natural Stone Design Fabrication, has transformed his stone fabrication shop from completely manual to a partially digital-operating facility. Natural Stone Design began in 1988 specializing in creating high-end, custom work.

They began fabricating with a bridge saw and a forklift, and all of their edge work was done by hand. A few years later an edge machine was added to the shop. Natural Stone Design had issues with the edging machine and bridge saw, so they began searching for better stone working equipment solutions.

Read their story! Expand the sections below to learn more about NDSF’s story and their partnership with Park Industries®.

A Partnership of Over 25 Years Forms

Natural Stone Design Meets Park Industries®

As they grew, Natural Stone Design moved into a few different buildings to handle the expansion. In 1992 Natural Stone Design bought their first piece of equipment from Park Industries®, a PRO-EDGE®.

Mike Medina reflects on this purchase, “Our experience with Park Industries® machinery has been a night and day difference above the other equipment companies. I have a mechanical background, so I understand machinery and Park manufactures quality machines.” Mike also understands the value of automation in the shop, which has contributed to Natural Stone Design’s growth over the years.

Investing in the Future

Investing in automation wasn’t a choice for Natural Stone Design. It was their way to continue growing and evolving. As time passes, manual labor has been harder to find. “Our shop is making the digital transition for a few reasons. One of the largest reasons is the future labor force is much more digitally knowledgeable,” Mike adds, “The digital experience has already helped us become more profitable.”

Natural Stone Design began with 3-4 employees fabricating countertops and has grown to about 40 employees today. Amongst their seven installation crews, about 5-6 kitchens are installed per day. Natural Stone Design ensures the care of their customers from beginning to end. Each customer is given one point of contact by assigning a Project Manager to specific projects.

Digital Machinery Produces

The Digital Experience

In 2013, Mike had the opportunity to purchase the company. Mike invested and diversified the projects the company worked on to include more commercial and tract work. As Mike transitioned into his owner role, he assessed production to figure out where their bottlenecks existed and focus on making improvements.

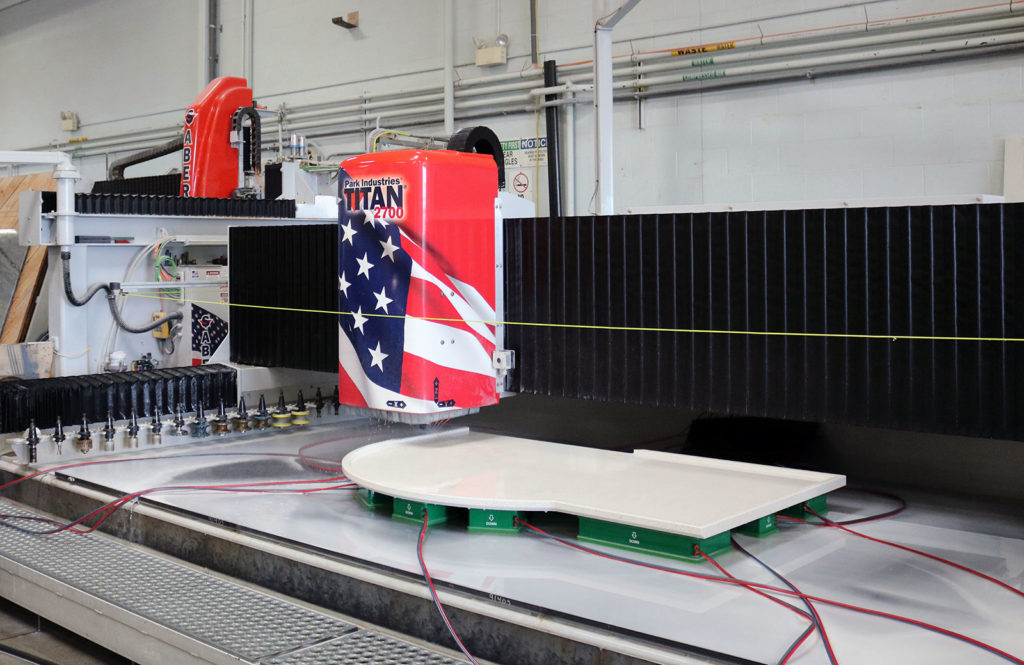

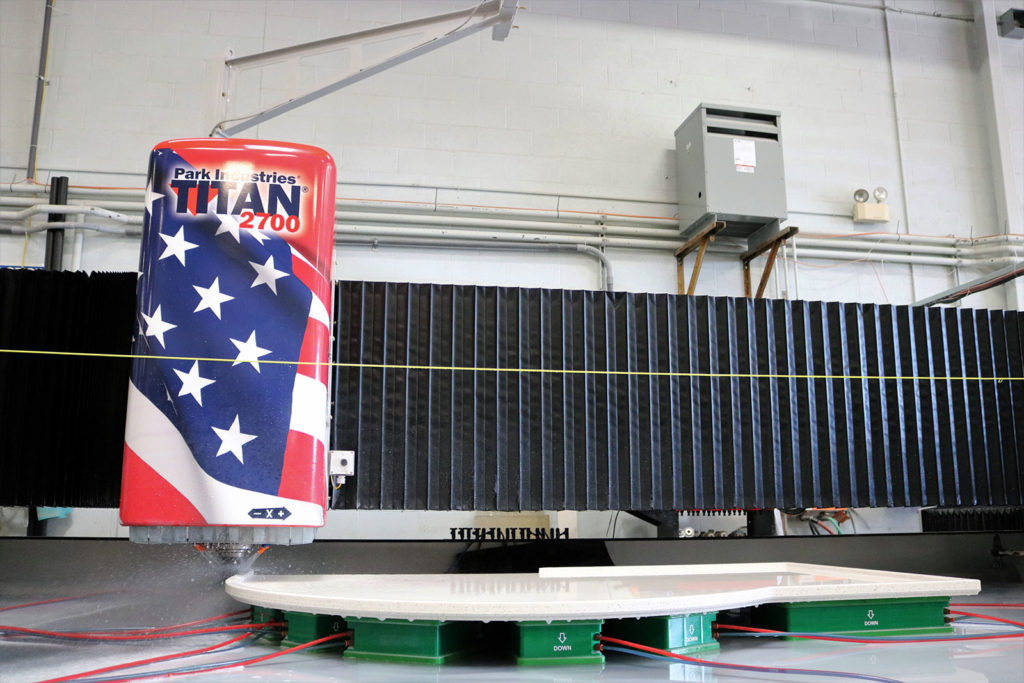

Since Mike took over the company in 2013, Natural Stone Design has tripled in volume. Mike largely attributes this to the addition of the SABER™ CNC Saw and the TITAN® CNC Router. The transition from manual to digital was difficult for quite a few employees. After trusting stick templates for 20 years, they found it challenging to transition to the digital equipment initially. Going digital has increased the efficiency of their shop since the same program works across all of the machines. It is seamless. Natural Stone Design’s customers appreciate the new options they have available to customize their project. Extra time is spent during the countertop selling process, but the value customers feel is immeasurable.

Machine Review

1. SABER™ Radius Work: The SABER™ 5-Axis CNC Saw has been a huge help for Natural Stone Design’s radius work, especially when fabricating projects with multiple radius edge work. Mike shares, “The SABER™ has allowed us to increase the yield out of my product by taking pieces and marrying them. When we are fabricating 100 vanities at a time, we can push a button and keep producing more.” Adding this machine to their shop has heavily impacted the amount of product they have saved.

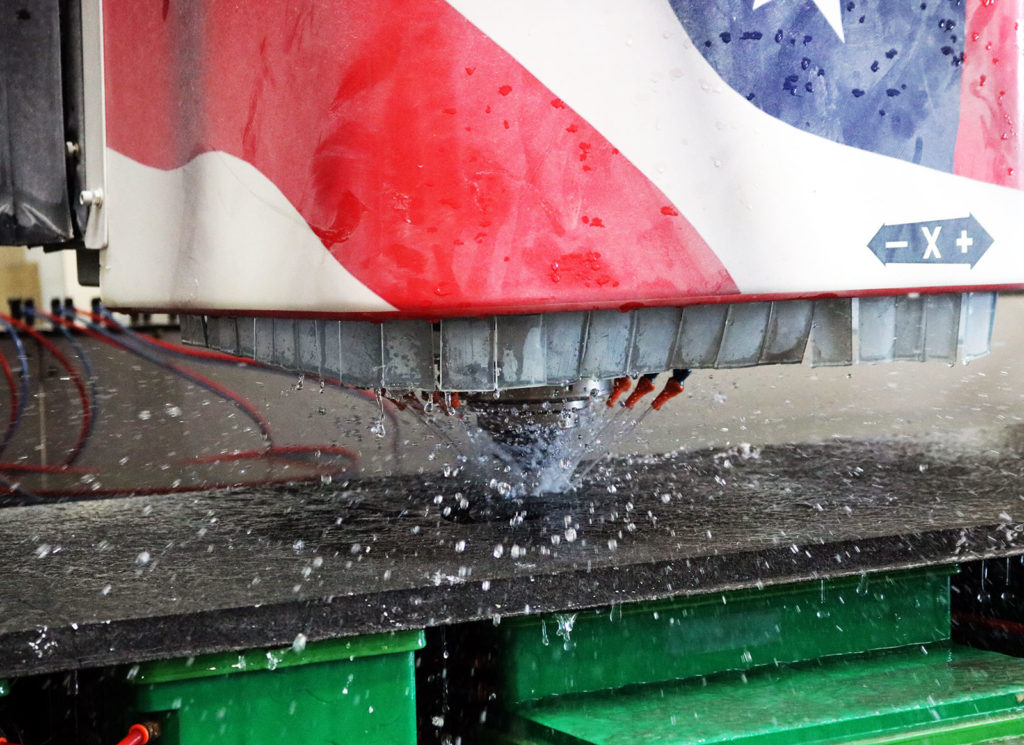

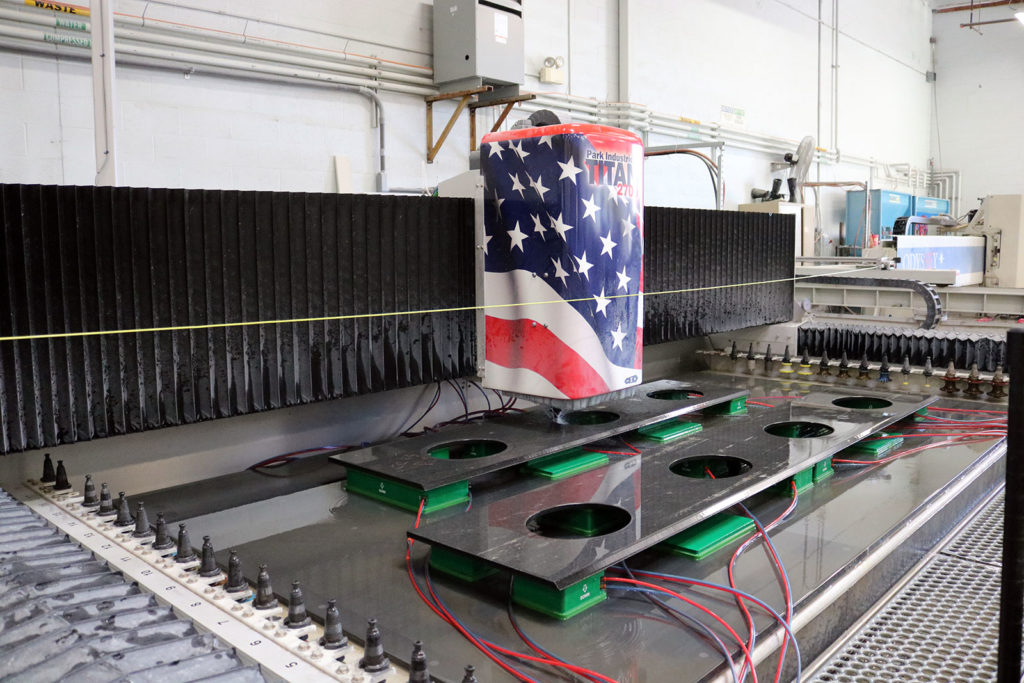

2. TITAN® Seamless Programming: Mike shares, “We can send the same program from the SABER™ to the TITAN® 2700 CNC Router. With extreme ease, our slabs are cut, mitered, and routed.” The effortlessness of how well the SABER™ and TITAN® work together has helped Natural Stone Design’s production immensely. The TITAN® has become a production powerhouse paired with the SABER®.

Quality & Synergy

Quality is Key

Natural Stone Design values their customers, which is why they ensure that every piece of stone fabricated will pass strict standards. With their emphasis on quality, Natural Stone Design chooses to use Park machinery as well as a hand inspection on each project. They make certain that no matter the size or type of project, the craftsmanship is excellent. Flat stone pieces are run on the PRO-EDGE® and the TITAN® CNC Router handles a variety of shapes and sizes.

Natural Stone Design depends upon the long-lasting durability of Park equipment, for example they have had their ODYSSEY CNC for 12 years, and it is still running strong producing for Natural Stone Design today.

Synergy with Park

Mike shares that Park’s support team works especially well over the phone. Park Industries® and Natural Stone Design speak the same language of stone fabrication. For example, unique projects and shortcuts on the machine are made possible by the two companies working together and giving strong advice. Natural Stone Design values Park’s strong customer service, the speed in which they receive ordered parts, and the care that is taken when resolving any issue.

Natural Stone Design formed a trusted partnership with Park Industries® from the very beginning. “Park Industries® is one of those places where we felt very comfortable working with them. We have always loved Park. We have had a great relationship from the start. Park has genuinely friendly people, and absolutely great products,” Mike shares.

QUICK FACTS

LOCATION

Sacramento, California, USA

TYPE OF FABRICATION

Stone Countertop

WEEKLY PRODUCTION

20-25 Kitchens

NUMBER OF EMPLOYEES

40

PARK EQUIPMENT

TITAN® 2700 CNC Router, SABER™ CNC Saw, PRO-EDGE® Edge Polisher (x3), YUKON® Bridge Saw, HydroClear™ Water System, Pathfinder® Digital Photo Station

PARK PARTNERSHIP

Began in 1992 with a PRO-EDGE®.

Featured Machines

PHOTO GALLERY

Contact Us

Ready for an upgrade?

Request information and we’ll respond promptly to discuss adding Park Industries® machinery to your shop! Or find your sales representative.

6301 Saukview Dr

St. Cloud, MN 56303