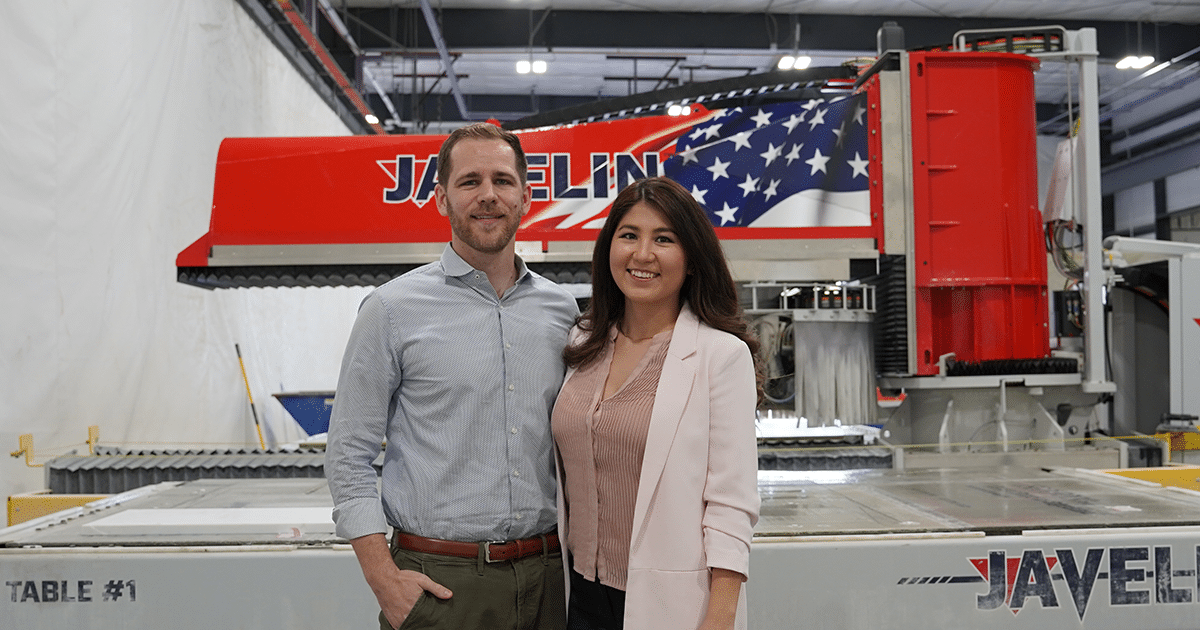

Richstone Surfaces, a family-owned business based in Chantilly, VA, stands as a testament to the enduring values of hard work, determination, and innovation. Sofia Dolan and Steven Bates, owners of Richstone, are a dynamic husband / wife duo making BIG moves including a gorgeous new facility featuring the first production JAVELIN™ CNC Sawjet.

Richstone’s Journey

Richstone Surfaces was founded in 2007 by Ablikem and Patigul Dolan, political refugees from Xinjiang, China. Despite facing financial hardships, they seized the opportunity to open a fabrication shop. Wickham, a former geology professor, was passionate about the stone world and relished the chance to work with his hands.

Sofia, the current CEO/Owner of Richstone Surfaces, joined the family business in 2008 while attending college, diving into customer service and sales alongside her sister.

When their initial foreign bridge saw frequently broke down in 2011, causing delays and frustrations, they realized the need for a reliable, American-made machine. They turned to Park Industries®, impressed by Park’s fully American-made and sourced products. This, paired with Park’s 24-hour customer service, made them the perfect partners to maintain Richstone’s high standards.

As Sofia’s father gradually retired, he worked with Sofia to transition her into the role of CEO and Owner. In 2015, Sofia proudly took the helm of Richstone Surfaces, showcasing her dedication and leadership in driving the company towards ongoing success.

Steven Bates, COO and Sofia’s husband, joined Richstone Surfaces in 2018, after helping the company from behind the scenes on commercial bids beside Sofia. With rapid growth, Sofia and Steven recognized the need to expand from their 5,000 sq ft facility to a larger one. Steven became COO in 2020 and played a pivotal role in the planning, construction, and operations of their new facility.

New State-of-the-Art Facility

Recently, Richstone Surfaces achieved a significant milestone with the finished construction of their new 25,000 sq ft facility. Completed over four years, their new facility includes a state-of-the-art digital stone fabrication shop and a stunning showroom filled with intricate work including a porcelain fireplace, backlight quartz wall, fluted walls, compound mitered reception desk, and plenty of more high-end stonework.

This expansion acts as a new home to Richstone Surfaces and demonstrates the company’s commitment to growth, innovation, and providing a greater experience for their customers.

Park helped them with the layout of the shop and was a true partner beyond just a machine in its creation.

Revolutionizing Production with the jAVELIN CNC Sawjet

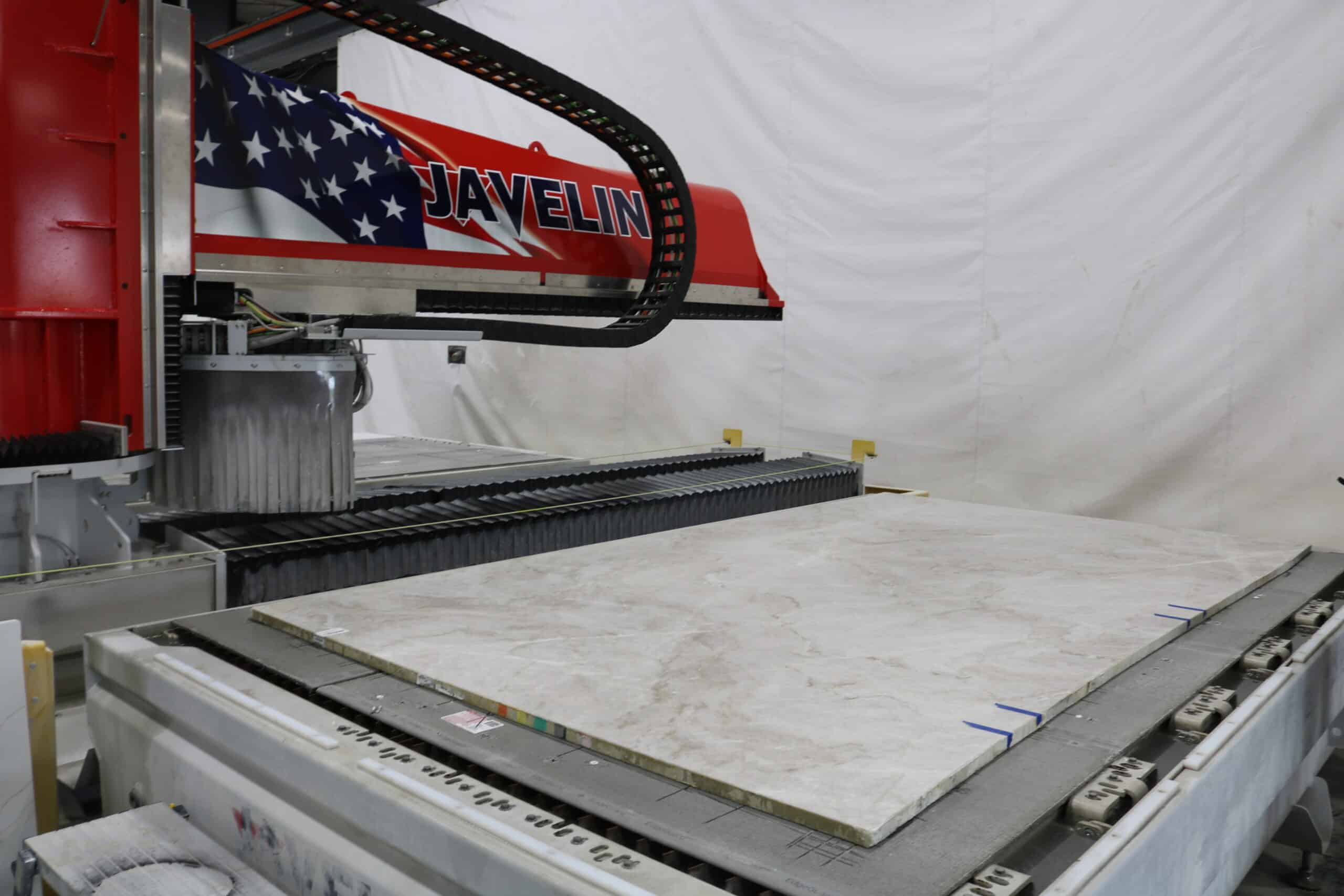

Central to Richstone Surfaces’ success is their investment in cutting-edge technology from Park Industries®. The addition of the JAVELIN CNC Sawjet to their facility has revolutionized their production process. The JAVELIN significantly increased their efficiency, accuracy, and production capacity, allowing them to undertake more complex projects and deliver exceptional results.

Steven emphasizes the company’s focus on exceptional products and customer satisfaction. He notes, “The JAVELIN was a game changer. For example, cutting porcelain took what used to be an all-day job with a bridge saw down to under 30 minutes. It cuts like butter.”

First production JAVELIN CNC Sawjet at Richstone Surfaces

One of the main reasons Richstone Surfaces invested in the JAVELIN CNC Sawjet was to attract larger clients who demand advanced automation for their projects. Steven highlights, “The JAVELIN enabled us to have the confidence and products that we need for our showroom to get designers and people in the door.”

The JAVELIN excels at handling intricate designs, from trending fluted edges to elegant brass inlays, demanding precise and efficient execution. Steven praises, “Having the JAVELIN has allowed us to scale our intricate work. We can now sell it at a more effective price rate for the market, thanks to better cutting efficiency and material usage yield.”

Streamlining Finishing with the FASTBACK® II Edge Polisher

In addition to the JAVELIN, Richstone Surfaces also invested in the FASTBACK II Edge Polisher, further pushing their production capabilities. The FASTBACK II streamlines the finishing process for flat edges, delivering a flawless finish efficiently.

Whether simple backsplash or full-size islands, the FASTBACK II has saved Richstone tons of manual labor and increased their production.

Partnering with Park Industries®

Richstone Surfaces recognizes the vital role of customer service, a value they also see reflected in Park Industries®. As Sofia highlights, “Customer service and reliability are our top priorities. Everyone at Park Industries® has been friendly, helpful, and always there for us.”

Park Industries®’ commitment to customer experience ensures Richstone Surfaces’ machines are always operational, supporting timely production and high-quality standards.

Looking Towards the Future

Richstone Surfaces’ journey is a testament to the power of hard work, innovation, and strategic partnerships. As they continue to grow and evolve, they remain committed to upholding their values and providing exceptional service to their customers.

Their partnership with Park Industries® has been pivotal in their growth, equipping them with state-of-the-art machinery and invaluable industry expertise. With Park Industries®’ support, Richstone Surfaces is prepared for continued success and ready for future opportunities.

Photo Gallery: Richstone Surfaces