Young, digital, and growing fast…Evolution Marble and Granite is carving its mark in the New Jersey area’s countertop market. With the help of some serious Park Industries® machinery (including the first SABERjet™ XP in the industry), they’ve quickly evolved into a lean, efficient shop that means business.

From Co-Workers to Co-Owners

The founders, Joe DeMelo and Chris Duarte, worked together as fabricators/installers for a different shop in the mid 2000s where they became good friends. Eventually, both left the company and went their separate ways. Over a decade later they realized how much each had grown with their stone skills, and thought they’d work well together. Joe had become skilled on the office side with programming, project management, quoting, and more. Chris had grown into a shop manager role, ready to oversee fabrication and machinery.

They decided to partner together and on January 4th, 2017, Evolution Marble and Granite was formed.

Finding The Right First Machine

When it came time to find the right manufacturer of stone equipment for the new shop, their positive experience with Park Industries® machinery and service previously made the choice an easy one. They were looking at a SABERjet™ originally, but being a start-up business, finances were tight. Then when a used (but well taken care of) FUSION® CNC Sawjet became available, they purchased it as their first major piece of equipment. The FUSION® was also the first machine Joe learned how to program on, so he liked the familiarity of it and knew it was a production beast.

With competitive pricing and a large amount of work coming in from multi-family projects, Evolution was quickly growing with the efficiency of the FUSION®. Joe recalls, “As soon as we got that FUSION®, our business sky-rocketed.”

“An Absolute No Brainer”

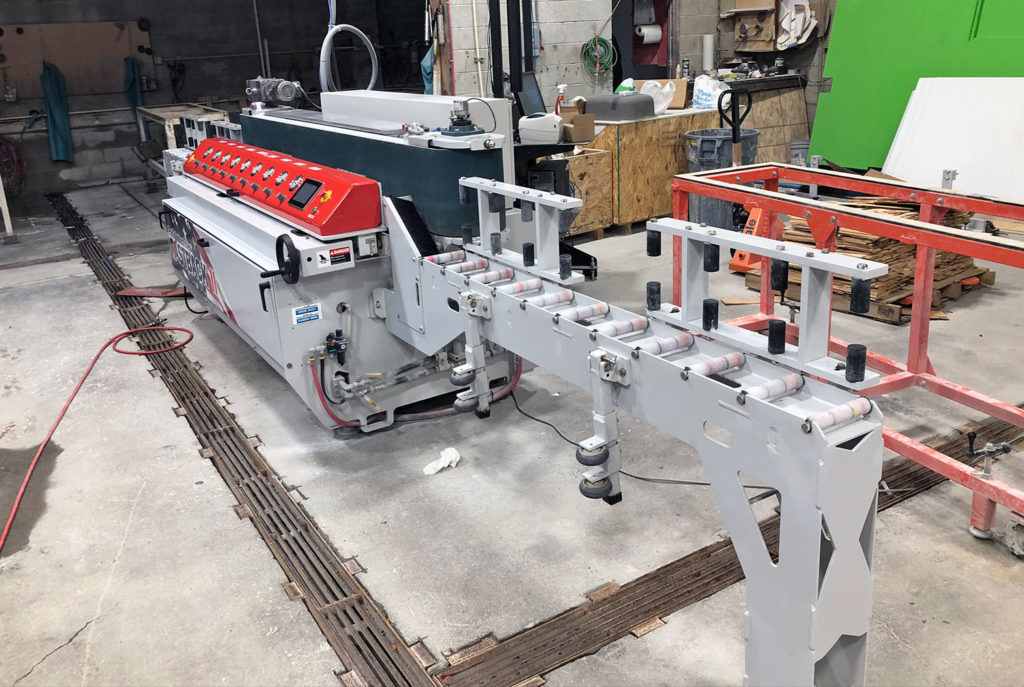

Soon after, they purchased the FASTBACK® II Edge Polisher to handle their flat-edge polishing. The FASTBACK® II provided a big boost to the shop’s production capacity with its fast, precise polishing. When asked what he likes about it, Joe responded, “Like everyone else says about it…it just prints money. That’s all it does. That is the most underrated machine in the shop.”

Joe, very passionate that every shop needs a FASTBACK® II, broke down just how efficient it is. He looked at it this way, “If you pay a guy $600-$700 (with insurance, etc) per week to polish backsplash, you are paying them at least $2800 a month. If you don’t put any money down on the machine, your monthly payment will still be much less than that. The machine will then do the work at least 4 times as fast…It can do in under 1 hour, what might take a guy to do in a full day. It also won’t complain, won’t take days off, and will eventually be paid off completely.”

He concludes, “If you do at least 2 kitchens a day, this is the machine you can feel good to buy without any hesitation. It’s an absolute no brainer.”

The FASTBACK® II was so efficient, eventually Joe started realizing the need for another saw. That’s also when he started hearing rumblings of an upgraded, more powerful sawjet coming out from Park…

SABERjet™ XP #1

With the excellent reputation of the existing SABERjet™ model and a great discussion with his sales rep on what’s improved in regards to the XP model, Joe signed a contract to save his spot for when the SABERjet™ XP 5-Axis CNC Sawjet was ready to launch.

Power and flexibility are the two key reasons why the SABERjet™ XP stood out as the right solution for Joe and Chris. With its 27 hp motor, it has the ability to cut quartzites with ease. Yet with the machine’s VFD and ultra-compact features, it also provided precise cutting of porcelains and ultra-compact materials… something Evolution was looking to fabricate more of and gain market share.

The compact design, small footprint, and high rail structure of the machine were all big pluses for Evolution. Finally, the Miterjet feature and the time they would save on insider miter corners was a major item they wanted in their next sawjet – something they saw the SABERjet™ XP does expertly well.

In September of 2019, Evolution Marble & Granite became the proud owners of the very first SABERjet™ XP installed in the industry. Since installing it, they have been able to take on more high-end custom work as desired. They are cutting porcelain, Dekton, and quartzites faster, with the quality of cuts improved. Joe recaps, “The SABERjet™ XP is a great machine. It gave us the ability to get into a new market. It’s 100% a game-changer for our shop.”

The Results: Lean Fabrication & Serious Reputation

Joe credits the SABERjet™ XP and FASTBACK® II for providing about a 60% increase to their shop’s production, without adding any additional employees or labor hours. With a four-man crew (including Joe and Chris), they currently produce anywhere between 900-1200 sq ft / wk. They are running a lean, efficient operation that continues to grow.

The benefits of the machinery are being felt beyond just improving their numbers. As a young shop, without a long history like others in the area, the ability to show off their industry-leading machines to potential customers has really helped them be taken seriously. Joe explains, “We feel our company is still just learning how to walk, but we are building our reputation fast and the reliable, high-tech equipment we use is a big part of that. We wouldn’t be where we are without Park Industries® machinery.”

Service & Partnership

There are two key reasons why they continue to choose Park Industries®:

- They feel having a partner to their business that they can tap into as a trusted advisor is invaluable.

- The service they’ve received for their machinery is unmatched. Joe explains, “There’s nobody like Park when it comes to customer service. They go over and beyond to keep us running and happy. I will pay more for a machine, just for the level of service I’ve experienced thus far.”

Joe has also strongly recommended Park Industries® to others in the industry. In fact, when a friend of his said he was looking at buying a CNC saw from a different manufacturer, Joe called him up and told him “Hell no man. You’ve got to buy Park.” The friend heeded his advice.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.