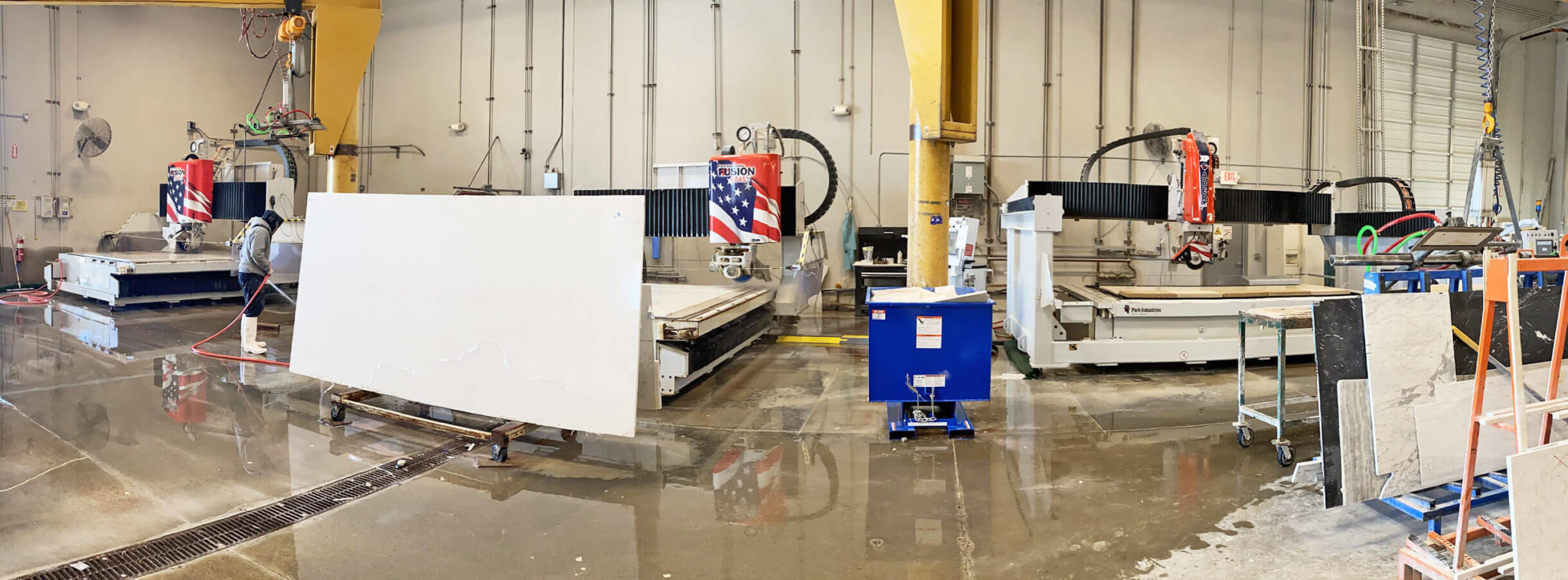

From the building, to the fabrication shop, to the end results of their work – just look and you’ll understand why Stockett Tile & Granite (AZ) has become a leader in the stone industry. A Park Industries® customer of 30+ years, their all-Park shop produces over 10,000 sq. ft. per week with a diverse lineup of machinery.

Stockett Tile & Granite

At 22 years old, Dave Stockett started his journey in the stone industry as a tile installer. Shortly after in 1974, Stockett Tile was created. Over the years the business grew from tile, to granite, to a variety of materials today. After 45 years of healthy growth and calculated risks, Stockett is a leader not just in Arizona, but in the entire stone industry – regarded as an artisan contractor who specializes in difficult, high-end jobs.

Flipping through some of Stockett’s mesmerizing portfolio of stone and tile work immediately proves why.

Read their story! Expand the sections below to learn more about Stockett’s story and their partnership with Park Industries®.

A Winning Culture

Building the Team

Like many businesses, Stockett Tile & Granite had modest beginnings, starting with just three employees. Today, they employ close to two hundred. Dave Stockett proudly shares, “The biggest strength Stockett has is the team.” Admitting that it may sound cliché, but they honestly credit their success to their team. He continues by adding, “We have the best team we’ve ever had in forty-five years right now.” This is accomplished through careful hiring and cultivating the team over time with training and learning opportunities.

“No Lose” Proposition

In business, there’s winning and losing. But what if you could remove the negative downside of that equation? That’s exactly what they do everyday at Stockett Tile & Granite. They have a saying, “We never lose, we either win or we learn.” This culture of learning has fostered a different mindset at Stockett and allowed them to grow by failing forward.

Growth through Opportunities

Expanding into Granite

In 1989, Stockett just did tile and they did it well, earning a respected reputation for themselves. Suppliers in the area began begging them to expand into granite. After some research, they partnered with a local fabricator, and within nine months were the majority of the fabricator’s business; an indication to Stockett that it was time to invest in their own equipment. In 1990 they traveled to a stone show to learn about machinery. This is where the partnership with Park Industries® began, starting with the purchase of their first Park machine, a saw called the PRODIGY (retired).

Boldly Forward

In 2008, during the recession, many business owners were forced to re-evaluate elements of their business to stay competitive. Many companies struggled to maintain market share, and Stockett was no exception. On the surface, it would seem like purchasing capital equipment in an economy rife with uncertainty may not seem like good timing, let alone a wise decision. But Dave saw it for what it was – the perfect opportunity to control costs and increase margins, and exactly what was needed during unpredictable times that demanded lower product prices. Dave knew they needed to become more efficient in the fabrication and lower processing costs. Thus, Stockett added their first CNC Sawjet, the FUSION®.

Initially, their bank and controller were upset with the purchase, but quickly realized they were wrong to be. Dave shares when they recognized the benefits, “We tracked the work that came off of it and realized, quickly, we had dropped our fabrication costs by half [just with the addition of the FUSION®].”

An Impressive Lineup

Over the years, Stockett continued to add Park equipment, and today they boast an impressive lineup – two FUSION®’s, a brand new SABERjet™ XP CNC Sawjet, three TITAN® CNC Routers, two VELOCITY® Edge Polishers, a PRO-EDGE® IV Edge Polisher, and a brand new FASTBACK® II Edge Polisher. Dave explains that certain machines are production machines, others are specifically to for custom work, demonstrating the versatility of their shop’s production with their diverse lineup of machinery.

Results & Partnership

Performance Wins

With a great team, a large facility, and their bountiful machinery, this all Park shop has a goal of about 1750 square feet per day specifically for their production work. The square feet of their custom work depends on the type of job and how complex it is. They are currently exceeding their goals and producing well over 2,000 square feet per day.

Partnering with Park

The value of a solid business partner cannot be overstated, which is why we’re so pleased by the many, highly complimentary comments that Dave had to share about Park Industries®. “If there’s a problem, they’re there to help; we have parts quickly; they communicate well; they train well; [Park] installers are second to none; the equipment lasts… these things are built well.” Dave concludes by saying, “We could’ve picked any other supplier of machinery, but we had to find somebody that we could work with, that would stand behind our product, that would service our product in a quick and efficient way. We couldn’t have done it without Park. It’s been a successful journey – very appreciative of Park Industries®.”

QUICK FACTS

LOCATION

Phoenix, Arizona, USA

TYPE OF FABRICATION

Stone Countertop & Exterior

WEEKLY PRODUCTION

10,000+ sq. ft. per week

NUMBER OF EMPLOYEES

200 total

PARK EQUIPMENT

SABERjet™ XP CNC SawJet, FUSION® CNC Sawjet (x2), TITAN® CNC Router (x3), VELOCITY® Edge Polisher (x2), FASTBACK® II Edge Polisher, PRO-EDGE® IV Edge Polisher, Pathfinder® Digital Photo Station, HydroClear™ Water System

PARK PARTNERSHIP

Began in 1990 with a PRODIGY Bridge Saw (retired).