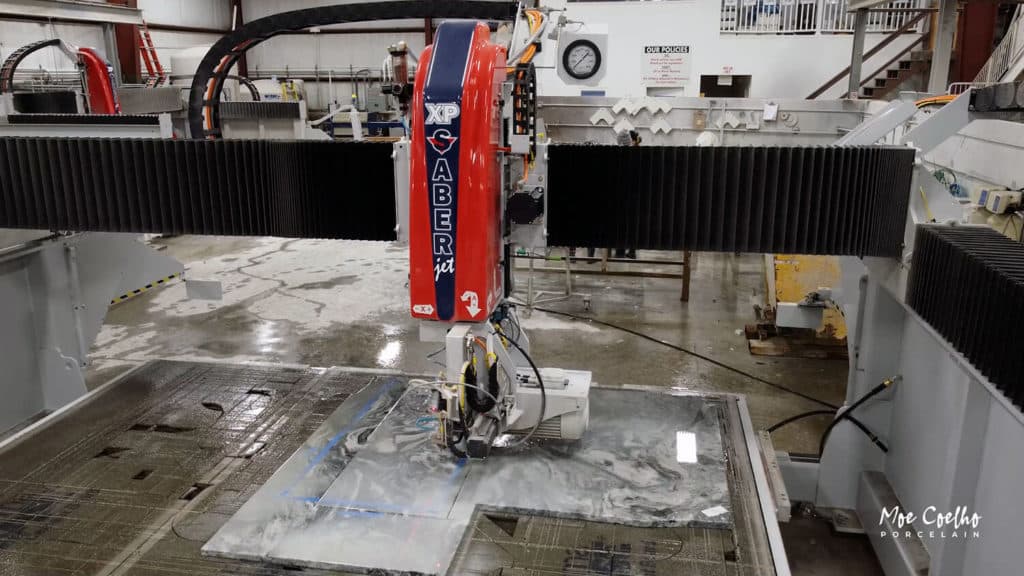

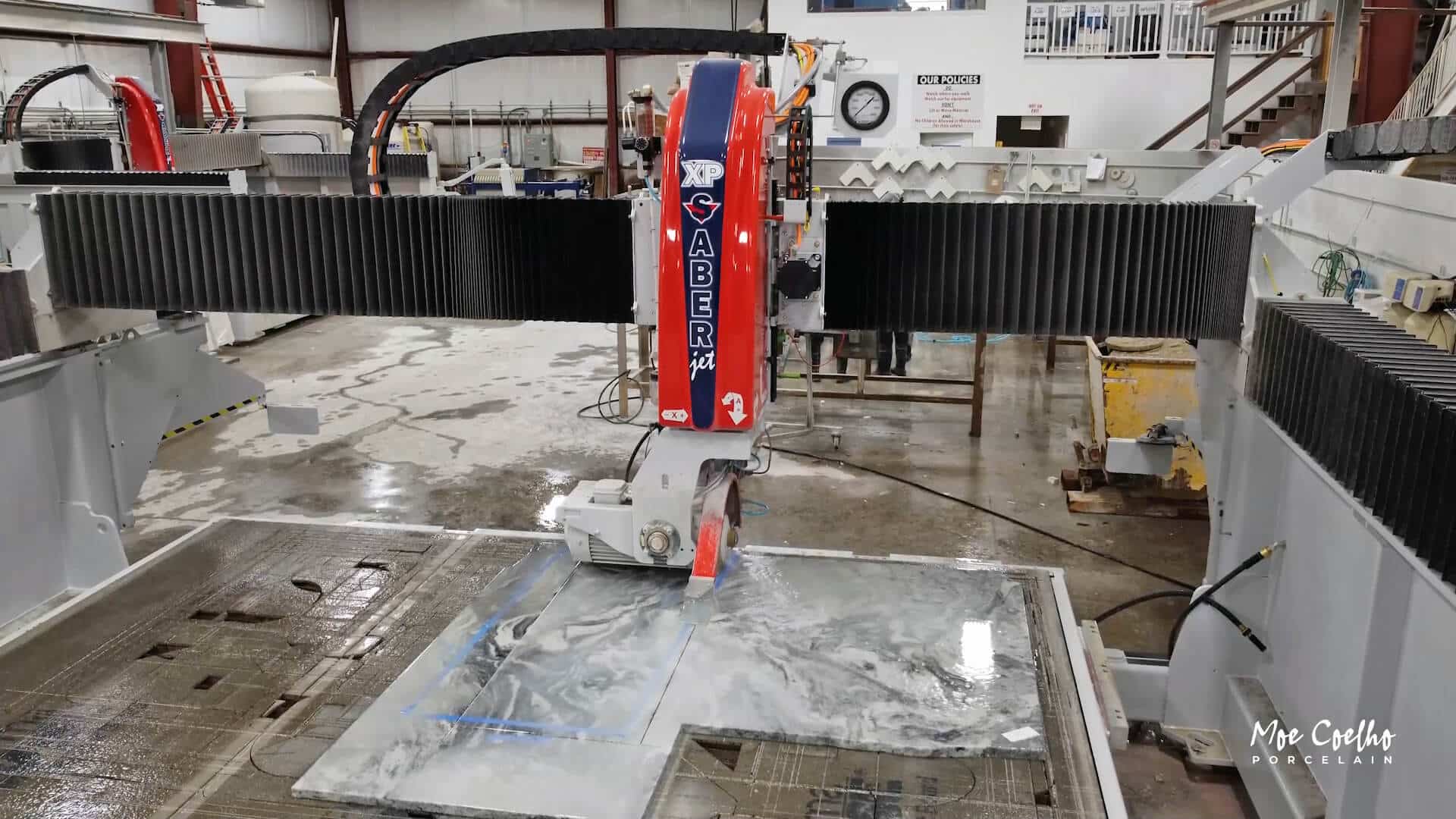

With a need to separate themselves from the ever-growing competition in their market, Moe Coelho leapt into porcelain with the help of Park Industries® sawjets. With two SABERjet™ XP’s powering both divisions of his business, Sudbury Granite and Moe Coelho Porcelain are producing about 2,000 sq ft / wk with only four employees in the shop.

Sudbury Granite / Moe Coelho Porcelain

Moe Coelho founded Sudbury Granite & Marble in April of 2001. In 2019, Moe Coelho Porcelain was formed to focus specifically on the fast growing porcelain market.

With an efficiency goal and a need to cut all types of materials, including porcelains and ultra-compact materials, Moe turned to the SABERjet™ XP CNC Sawjet to be the backbone of his shop’s production.

Read their story! Expand the sections below to learn more about their story and partnership with Park Industries®.

Park Partnership Begins

Foreign Findings

After some research, Moe chose to purchase Park Industries® machinery to help start his business, specifically because he felt they had quality machines and were a very safe choice. They started with a YUKON® Bridge Saw and WIZARD Deluxe Polishing Station.

Years later, they were growing rapidly and Moe was looking to purchase more machinery. He made some trips to Italy and elected to purchase foreign equipment this time. Moe explains what they learned in a short time, “The machines were good. The service was bad. The bad outweighed the good.” He felt that both the Italian machines and Park Industries® made quality machines, but his previous experience with Park’s service left his expectations high. Great service was now a necessity for Moe and the other company was unable to fill Park’s shoes.

Soon after “learning too many things the hard way”, he was back to buying machinery from Park Industries® and Moe’s worry of unnecessary downtime was in the rearview.

Porcelain & New Sawjet

A Porcelain Trip

Moe, who’s always had a keen vision for future opportunities, travels frequently to see what is happening in the stone world, so he can make good decisions with his business. In the fall of 2019, during a trip exploring the porcelain trend, he ordered some material to arrive the following March. He felt his team of skilled fabricators could be quick to respond to the wave of porcelain materials by applying the right technology.

He was looking for the best machine to cut it, and he wanted it installed right before the material arrived. Moe was in the market for a new sawjet.

SABERjet™ XP Time

He called his sales advisor at Park Industries®, and in March of 2020, a new SABERjet™ XP 5-Axis CNC Sawjet was installed at Sudbury Granite & Marble. Moe comments on his new machine, “I am extremely happy with the SABERjet™ XP. It’s working very well for cutting porcelain and any other material that comes through the shop. I am already hoping I can buy another one soon.”

Moe did his research on other sawjets, and he felt the machine was simply ahead of the competition with its versatility and precision. He points out the 5-axis design and mitering capabilities (including the MiterJet feature for inside corners) as two key reasons why the SABERjet™ XP stood out as the top choice. That, and knowing he would have great service from a company who would stand behind their machine.

Moe comments on how the machine has helped them grow, “Prior the SABERjet™ XP, we never cut Porcelain or other materials like Dekton. We’ve been able to jump right into that market and not miss a beat. The machine’s mitering capabilities have been huge for us to do this, as those materials are almost always finished with a mitered edge. Time spent cleaning up inside mitered corners has been eliminated thanks to the mitering waterjet.”

Moe jokes that he will not recommend the SABERjet™ XP…to any shops close to him. To shops out of his state, Moe highly recommends the SABERjet™ XP.

SABERjet™ XP Two Table

Sudbury Doubles Down

With the success they were having with their first SABERjet™ XP, and the need for more cutting production due to the slower cutting process of porcelain, Moe was extremely pleased to see the release of the two table SABERjet™ XP CNC Sawjet. He pounced on the opportunity and installed one of the first ones in January of 2021.

Moe shares, “Now we can use our single table SABERjet™ XP specifically for cutting our porcelain work, and let the two table handles everything else. I do foresee a point where we reverse that, and have the two table cutting our porcelain work and our single table cutting granite, marble, quartz, etc.”

With the addition of the two table sawjet and overhead crane system, Sudbury now produces approx. 2,000 sq ft / wk with only 4 guys in the shop.

Moe proudly reflects, “It is not about how much you get out the door…it is about how efficiently you do it. To produce that much with only 4 people is a thing of beauty. The two table sawjet is the best investment I’ve ever made.”

Final Recommendation

The Company

What stands out about Park Industries® for Moe is uptime performance from the machinery and getting knowledgeable help on the other end of the phone every single time he needs it. When asked if he’d recommend Park Industries® to others in the industry, Moe gives a similar answer, “If they are far away from me – I’d definitely recommend Park Industries®. If not, I’m okay with competitors finding out the hard way.”

QUICK FACTS

LOCATION

Hopedale, Massachusetts, USA

TYPE OF FABRICATION

Countertop & Exterior

WEEKLY PRODUCTION

1,700 – 2,000 sq. ft. per week

NUMBER OF EMPLOYEES

4 in Fabrication Shop

PARK EQUIPMENT

SABERjet™ XP CNC Sawjet (Single Table), SABERjet™ XP CNC Sawjet (Two Table)

PARK PARTNERSHIP

Began in 2003 with a YUKON® Bridge Saw.

PHOTO GALLERY

Featured Machine

Contact Us

Ready for an upgrade?

Request information and we’ll respond promptly to discuss adding Park Industries® machinery to your shop! Or find your sales representative.

6301 Saukview Dr

St. Cloud, MN 56303