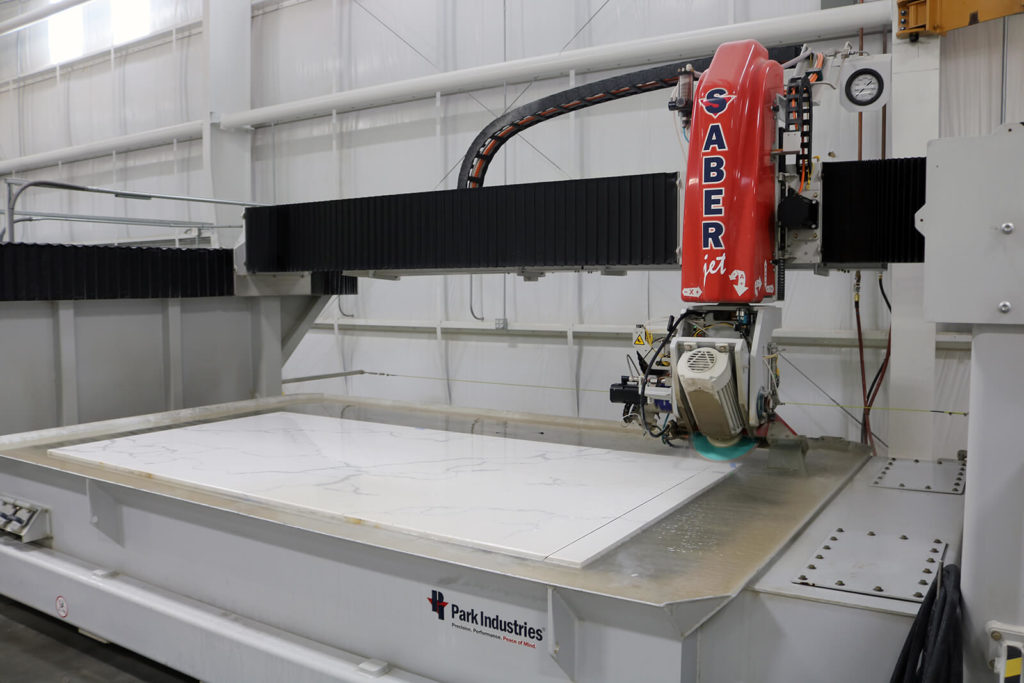

Billy Waters has seen exceptional growth since starting Texas Custom Granite, crediting this to unrelenting standards of quality products, customer service, and the latest technology. They only run Park Industries® machinery, producing about 3750 sq. ft. per week of high end, custom work in one of the cleanest operations you will see in the stone industry.

Texas Custom Granite Co.

Missed deadlines and a lesser product are simply not an option for Billy Waters. After experiencing this from subbing out stonework for his remodeling business, Billy took control into his own hands. With some room on his personal property, he divided up the area and built his own fabrication shop, naming it Texas Custom Granite Co. Fast-forward a decade and Billy is opening up a beautiful, brand new 60,000 sq. ft. facility. It’s filled with a luxurious showroom, an indoor slab yard, and the latest stone fabrication machinery.

Billy specializes simply in fabrication. While Texas Custom Granite focuses on custom stonework and high end countertops, Billy also founded Buffalo Barn Doors (decorative wood doors) and fabricates for other wood and metal applications.

QUICK FACTS

LOCATION

Houston, Texas, USA

TYPE OF FABRICATION

Stone Countertop (Focus on high-end custom work)

WEEKLY PRODUCTION

3750 sq. ft. per week

PARK EQUIPMENT

TITAN® CNC Router (x2), SABERjet™ CNC SawJet (x2), FASTBACK® II Edge Polisher, VELOCITY® Edge Polisher (x2), HydroClear™ Water System, Pathfinder® Digital Photo Station

PARK PARTNERSHIP

Began in 2008 with a PRO-EDGE Polisher.

Q & A with Billy of Texas Custom Granite

1. How did you get your start in stone?

Billy: I started a remodeling company about 15 years ago. I was using another stone fabrication company in Houston for our stonework and was not happy with the service I was getting. The jobs were often behind the promised time frame or the quality was not to my expectation. I had the space to build a shop on some property we were living on so I decided to jump in the stone countertop business so that I could control the timing and quality.

2. Who is Texas Custom Granite Co?

TCG is a Houston based stone fabrication company that produces countertops for residential builders, commercial builders, and remodelers. We pride ourselves on doing it right. That has meant investing in what we believe is the best fabrication equipment available to deliver quality countertops second to none in our areas of business.

3. What equipment is that?

Park Industries® machinery, of course. I first discovered Park at a trade show in Chicago about a year or so I after I started TCG. Until then, we were cutting with a bridge saw and using hand routers to create the edges. Although the edges were pretty good, the time to create these edges was killing our production and I was desperate to find a way to speed up the process.

I happened to walk by the Park Industries booth and found the solution for us at the time. We purchased a PRO-EDGE® [Edge Polisher], which was the beginning of our relationship with Park Industries®.

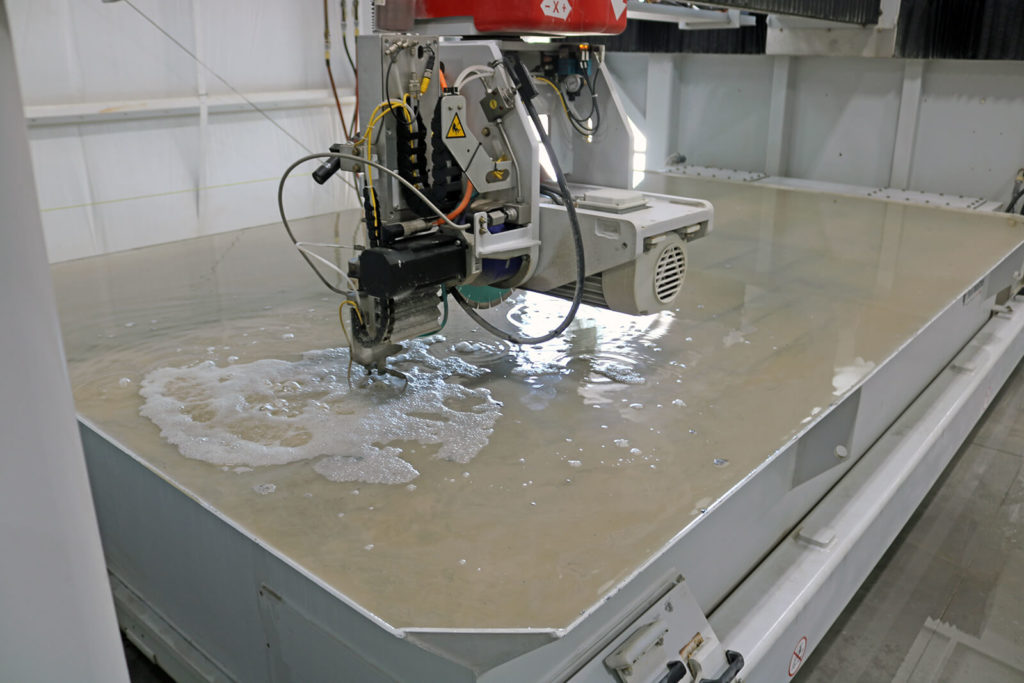

4. Somewhat hard to find in the stone industry, your shop is nearly spotless! How?

The shop stays clean because we clean it daily. Everyone has a section of the shop to maintain. This is overseen by our shop manager everyday and then myself.

You can have a clean shop if it’s important to your culture. If it’s not important, and you think no matter what you do it will get dirty “like every other shop,” then you are 100 percent correct, “it will look like everyone else’s shop.” A clean shop was only a dream in my last building. Now it’s a reality because it is expected and inspected daily.

5. Going digital… why did you do it and what were the results?

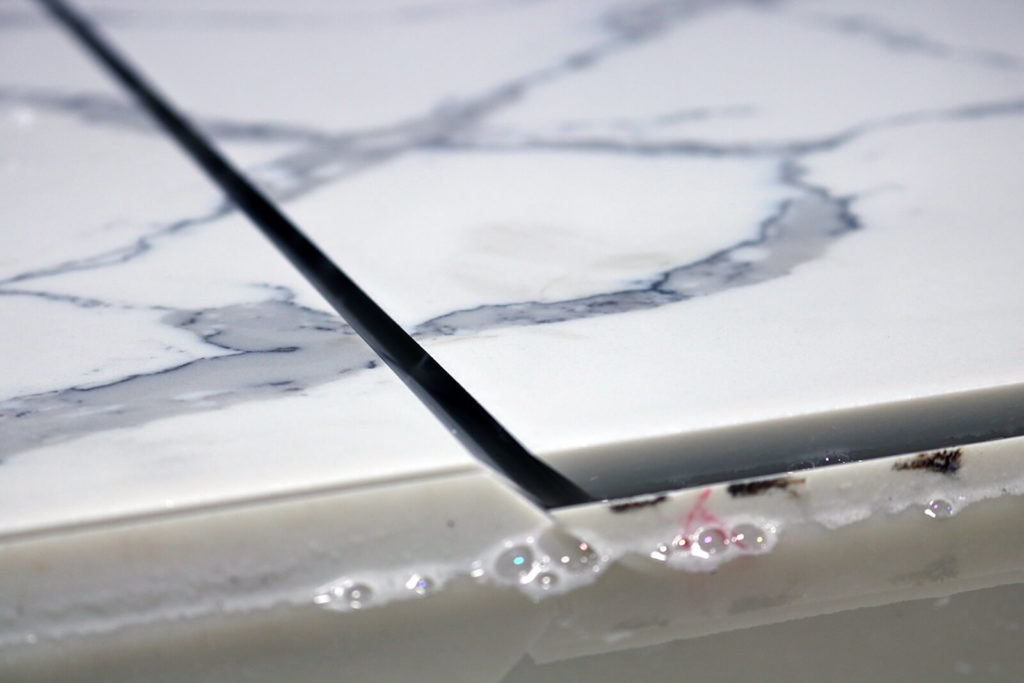

We decided to go digital when we bought our first FUSION® [CNC Sawjet]. This purchase forced us to go fully digital and it was a natural evolution as we continued to grow. The changes put us in the major league. I still love to hear how customers are blown away when they see exactly what goes into making their countertops. From the digital template to the slabsmith layout, customers get more of a hands-on approach to their investment. That has become a game changer. The peace of mind a customer feels when they see our process is priceless.

6. You have doubles of nearly every machine. What is your philosophy around getting two of each machine for your process?

We have always felt that redundancy was the best way to ensure maximum uptime and production. We run a very tight turnaround time and our commitment to deliver countertops on time to the customers was worth the investment of purchasing two of everything.

This philosophy has served us well, versus getting perhaps a two tank sawjet. If that machine needs downtime, you won’t be able to use either table. With two separate machines, if one needs downtime, I can still run parts on the other. I don’t know of a better way to prepare for it than with machine redundancy.

7. SABERjet™ over other sawjet solutions?

The SABERjet™ [CNC Sawjet] was really our only choice. We did look at a robot, but the SABERjet’s mitering capabilities and compact design fit our shop better. The system in place with Park Industries® has also worked so well for us for the past 10 years that I was not interested in gambling on a solution from a different company. If it’s not broke, don’t fix it.

Surrounding yourself with a reliable partner is key to any business success. We have found that partner in Park.

Billy Waters| Texas Custom Granite

8. How has Park Industries® helped you reach your goals?

The investment we have made in Park’s machinery has allowed us to take on larger projects and multiple home builder accounts that require quality countertops with a very short lead time. I now have the luxury of more quality time with friends and family, the ability to give back wherever we can, and more freedom in my personal life. I have always wanted TCG, the company, and all its employees to demonstrate character and integrity. I think that by setting the expectations of the product we deliver by the technology we employ is a great place to start.

9. “Why should I do business with Park Industries®?“

You are investing into your own company with a partner that understands your needs. They have a solution for every aspect of fabrication in a shop. We started small and grew because we were able to produce a quality countertop. As our needs for machines grew, Park always had a solution. Surrounding yourself with a reliable partner is key to any business success. We have found that partner in Park.

I have been working with Park for 10 years and we now have a shop full of their machines. The reason we have stuck by their side is because they have stuck by ours. Loyalty both ways. They make quality equipment and have the service to back it up. I don’t know that we could ask for more than that.

10. Any “extra mile” stories from Park’s service?

We recently moved into our new fabrication facility and Park sent a technician to help relocate our two TITAN® [CNC Routers] that we had in our old shop. Moving into a new facility without affecting our current workload was a monumental task. Park stepped up for us to make the transition as seamless as possible.

11. What have been the greatest benefits in working with Park Industries®?

One of the most important goals for me was to find a US based company that built quality equipment and backed it with exceptional service. I had issues getting answers and parts for my original Italian made bridge saw and needed to find a solution that would alleviate downtime should a machine repair be needed. The fact that I could call Park and get a technician on the phone and parts shipped out the next day was huge. Secondly, Park is always thinking towards the future. It is nice knowing that they are looking for ways to improve their technology, which helps increase productivity and the quality of the finished product.

PHOTO GALLERY

Featured Machines

Contact Us

Ready for an upgrade?

Request information and we’ll respond promptly to discuss adding Park Industries® machinery to your shop! Or find your sales representative.

6301 Saukview Dr

St. Cloud, MN 56303