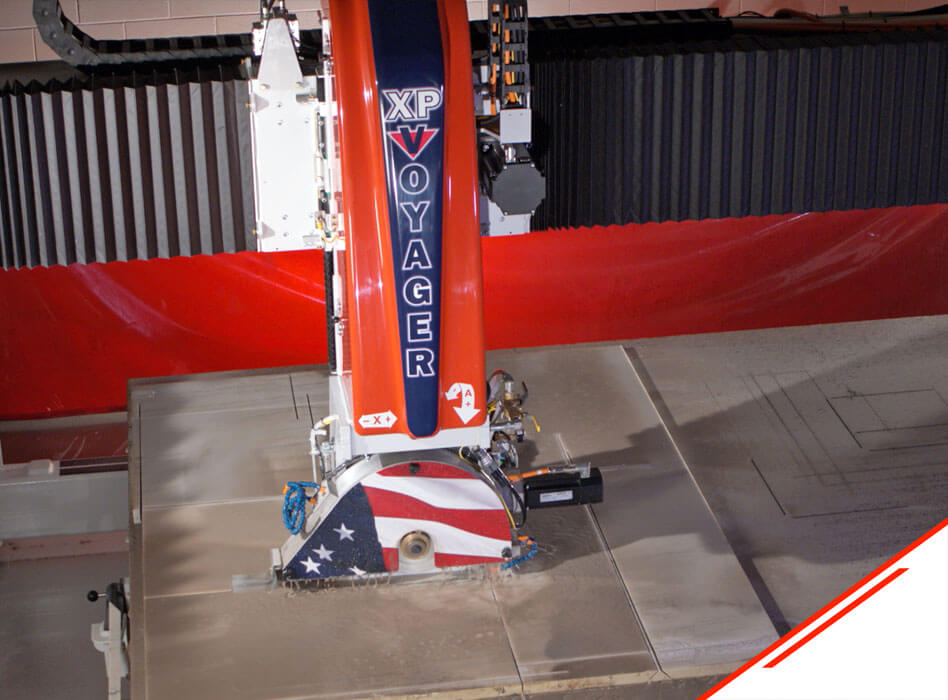

After years of wanting to go digital, Melling Granite (UT) made their maiden voyage into digital stone fabrication with the VOYAGER™ XP 5-Axis CNC Saw. In fact, they became the proud owners of the very first one to be installed in the industry.

From Used to New

Mark Melling didn’t need to buy a machine from Park Industries® to experience their renowned customer service. After years of running a DESTINY CNC Router, two PRO-EDGE® Polishers, and a COUGAR Bridge Saw – all of which he bought used elsewhere – he never once felt like he received lesser care because he didn’t buy them new from Park.

Mark states, “Park stands behind their products. Their machines just keep running and they keep providing excellent service and fast delivery of parts. “

When it was time for Melling Granite to make the digital leap and buy a new CNC sawing solution, the care they had experienced thus far is what it came down to for Mark when making the final decision. Mark explains, “Knowing that they’ll still be supporting our VOYAGER™ XP 20 years from now, made all the difference in the world to me.”

The VOYAGER™ XP Arrives

In October of 2019, Melling Granite’s first CNC machine and Park Industries® first VOYAGER™ XP, were sitting on the truck in the parking lot, ready to be installed. Mark shares about getting the first one, “There was a little bit of that guinea pig feeling at first, but I know Park. I have complete confidence in them and once again they proved why.”

Mark recalls everything including the installation and training going very smoothly, labeling the entire process as a ‘good experience that felt right’.

The Results

The entire fabrication shop at Melling Granite has felt the positive impact of the VOYAGER™ XP. Going from the manual COUGAR Bridge Saw to the new 5-axis CNC saw has made the shop much more efficient.

Mark explains, “There’s no more time wasted tracking down stick templates. The tooling costs for hand fabrication have gone way down, mainly due to the ability to cut all the sinks precisely right on the CNC saw without error or waste. It has also taken all of the guesswork out of the process, which feels great.”

Mark says what he likes most about the machine:

- TightCut™ blade plunging feature – It’s given them much more material yield with the ability to nest parts closer. No more babysitting the machine and worry about it cutting into other parts like his manual saw.

- 27hp motor – He feels the machine just doesn’t slow down and can handle quartzites and more without a problem.

- Table size & mitering envelope – He’s enjoyed the ability to throw a big island on the large table and be able to miter the edges without having to hang some of the stone of the edge and clamp it down like the previous saw.

Looking Back

During his research of CNC Saws, Mark spoke with another shop that purchased a different brand of CNC. They’ve since mentioned some issues and software glitches where the machine has cost them rework and material. Mark states that Melling Granite has encountered no such issues and he is very happy with their investment in the VOYAGER™ XP. He is proud to continue to choose Park Industries®.

He concludes, “From everything I’ve experienced, Park Industries® is the way to go. Everything is just better with Park.”

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.