Making adjustments and repairs to restore component accuracy to the Micro Adjustment

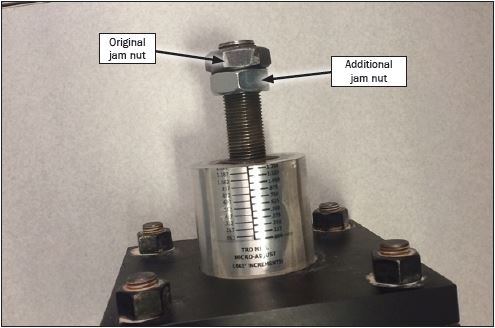

The jam nut requires a 1-1/8″ wrench. Remove the micro adjust knob and the threaded rod using either the knob with jam nut or using two jam nuts locked together DO NOT clamp anything on the threads (Jam nut is ¾” – 16 – Park PN# 2521200 or may be available locally).

Clean the threads on the threaded rod, the micro adjust knob and the jam nut then apply red threadlocker to the lower portion of the threaded rod.

Using a 1-1/8″ wrench on the top jam nut reinstall the threaded rod back into the top of the cylinder and tighten until it bottoms out.

Remove the jam nuts and reinstall the micro adjust knob and jam nut.

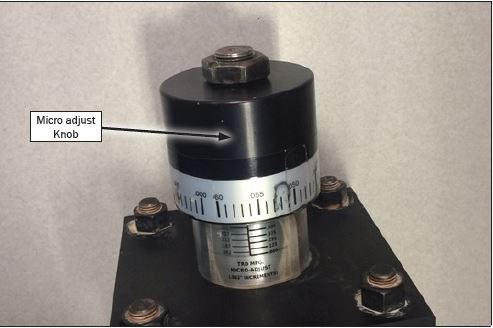

Once the Micro adjust knob is installed the air cylinder gap must be set,

A. Extend the drawbar

B. Place the air cylinder gapping tool under the drawbar the tool should fit snug but not too tight, adjust the micro adjust knob accordingly

C. Retract the drawbar then tighten the jam nut on top and the Allen head set screw on the side of the micro adjust knob

D. Confirm the air cylinder gap is correct after everything is tight

Check and adjust the gripper depth to 3.573” +- 0.004

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.