This document outlines key elements that should be followed to maximize spindle life. Failure to follow all of these items listed below will reduce the life cycle of the spindle.

Water Quality

Use only fresh, tap water through the spindle (per machine specifications – contact Park Industries customer service for details. Poor water quality can cause buildup of stone dust and scale on the spindle taper and tool holder cones leading to poor tool-to-spindle contact and accelerated taper wear. Poor water quality can also reduce gripper function allowing the tool to move or vibrate in the taper which causes taper wear.

AIR

Provide clean, dry air to the spindle (per machine specifications – contact customer service for details).

► Maintain the machine’s desiccant filter as per maintenance schedule (*For full procedure details refer to the Operation and Maintenance Manual).

► Air tubing going into the spindle are used to prevent internal contamination. This air flows out of the spindle via non-contact seals at the upper and lower ends keeping contaminants out. If supply air contains moisture, the moisture flows through the inlet lines and into the spindle causing corrosion, grease contamination, and early bearing failure.

Keeping the Spindle collision free

Avoid crashing the spindle into stone, vacuum pods, or other objects. Impacts to the tooling, tool-holders, or spindle will transfer through to the spindle bearings leading to premature failure.

Tool Holders

Clean tool-holder cones as per maintenance schedule (*For full procedure details refer to the Operation and Maintenance Manual).

► The spindle must hold the tool solidly with uniform contact. Buildup on the tool-holders can cause a high spot. The tool-to-spindle contact is then reduced allowing the tool to rock in the spindle as the machine runs. This condition will cause taper damage.

Tool-holders should be replaced if they have any rust on the cone portion.

► The spindle must be able to hold the tool-holder with uniform contact on the mating

surfaces. Rust spots will inhibit uniform contact allowing the tool to rock or move as the

machine is running causing accelerated taper wear.

The spindle must be able to hold the tool-holder with uniform contact on the mating surfaces. Rust spots will inhibit uniform contact allowing the tool to rock or move as the machine is running causing accelerated taper wear.

Use only tool-holders that meet JIS B 6339 standards.

► Poorly manufactured tool-holders can reduce tool-to-spindle contact resulting in loose

tooling and premature spindle taper wear.

Spindle Taper

• Lubricate the spindle taper as per maintenance schedule (*For full procedure details refer to the Operation and Maintenance Manual).

► Lubrication will extend spindle life by reducing direct metal-to-metal contact. Proper taper lubrication will also reduce tool sticking problems.

• The taper of the spindle must be kept clean and free of stone dust buildup, scale, and debris.

► The spindle-to-tool connection must be uniform across the mating surfaces. Buildup on the taper can cause a high spot. The tool-to-spindle contact is then reduced allowing the tool to rock in the spindle as the machine runs leading to taper damage.

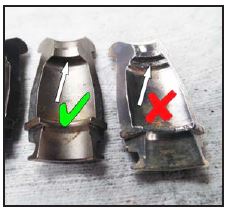

retention knobs

• Use only high-quality retention knobs that meet DIN 69872 Form A standards.

► Poor quality retention knobs can break and cause significant taper damage.

• Inspect retention knobs and replace any that are worn or corroded. Pay particular attention to the underside of the knob where the gripper fingers contact.

► Worn retention knobs will reduce the ability for the spindle to hold the tool securely. The tool can then vibrate in the taper causing taper damage.

Do not change machine settings

Do not manipulate the drawbar parameters to override built-in safety alarms.

• The machine has alarms to protect itself from running with a badly worn gripper or badly out of adjustment gripper depth. Do not change parameters in the Config. Screen to override these alarms.

Air Cylinder adjustment

Maintain the correct air cylinder stroke.

• If air cylinder stroke is not set correctly, the gripper will not be set to the correct depth. This can cause the tool to be held loosely causing taper wear (*Check with the air cylinder gapping tool).

Gripper Health

• Remove and maintain the gripper per maintenance schedule (*For full procedure details refer to the Operation and Maintenance Manual). It is critical the gripper be replaced if wear is detected on the gripper fingers.

► A worn gripper is not able to hold the tool securely. This allows the tool to move or vibrate in the spindle as it is running causing taper damage.

Maintain the correct gripper depth.

► A poorly adjusted gripper can cause the spindle to hold the tool too loosely or clamp on the wrong part of the retention knob causing accelerated taper wear (*Check with the depth caliper, for full procedure details refer to the Operation and Maintenance Manual).

Tooling

Tooling:

• Replace worn tooling. This is especially CRITICAL on the mill bit.

► Worn tooling can generate extreme side load on the spindle. If a mill bit is worn down to the metal stud, it can drag through the stone and eventually be ripped out of the spindle causing severe taper damage.

Ensure tooling is in good condition and cutting segments are not glazed over.

► Glazed tooling will not remove material effectively and can cause extreme side load

pressure on the spindle

Tool Holder clips

Ensure tool pocket locations are accurate and that spindle is correctly oriented to the tool

pocket.

► Inaccurate tool pocket locations can cause the spindle to crash into tool clips or other tools causing bearing or taper damage.

• When doing manual tool changes, ensure tool clip is empty before sending machine to drop off tool.

► Sending machine to put away a tool in an already occupied tool pocket will result in the

spindle crashing into that tool. Bearing and taper damage may occur.

Drive Belt

Do not over-tension the drive belt.

• An overly tensioned belt will lead to excessive side loads on spindle bearings leading to

premature failure.

Run Spindle Warmup

Run the spindle warm up routine (see Operation and Maintenance Manual for proper procedure).

• Spindle grease and bearings need to be brought to operating temperature or bearing damage may result.

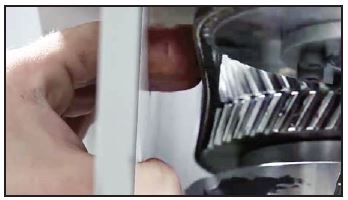

Replace worn or damaged spindle drive keys

Replace worn or damaged spindle drive keys

• Tool-holders can hang up on worn drive keys preventing the tool from fully seating into the spindle’s taper. This may cause damage to the spindle taper.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.