LOWER THE NOZZLE ON TABLE AND OPEN THE JET TO BLEED ANY PRESSURE FROM THE SYSTEM BEFORE WORKING ON THE JET ASSEMBLY

FOLLOW LOCK OUT TAG OUT PROCEDURES

- This is a procedure to help diagnose a hp leak at the jet head assy

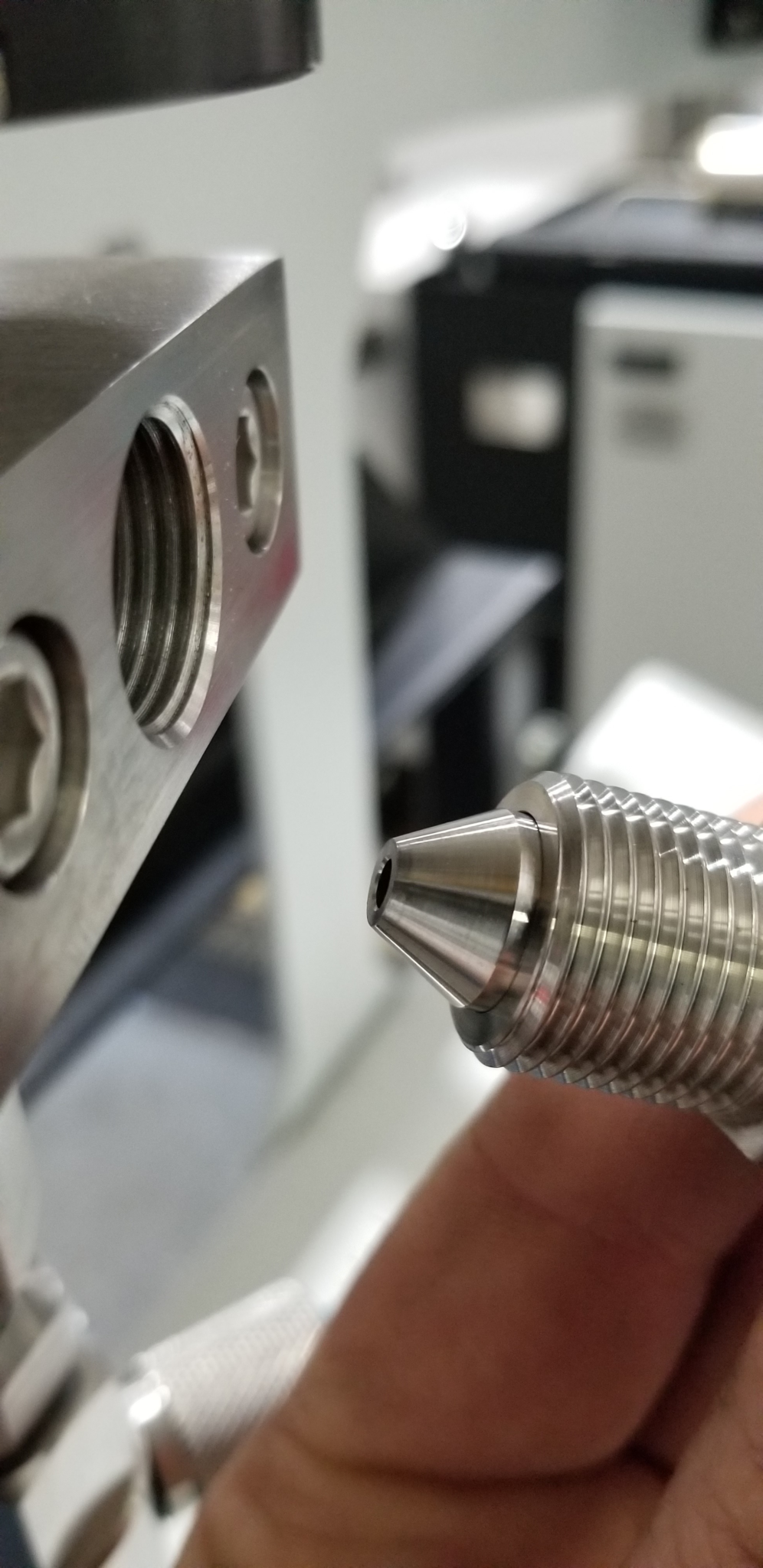

- This applies to jet edge and accutream jet heads(pictured is a accustream head)

If you have leaking or spraying under the block you may have a bullet that is loose or a component that is worn out

(notice the ring on the face of the bullet)

Your adapter may also be bad (where the bullet seats)

When installing the new Bullet/adapter slightly twist the nozzle assy as you tighten the adapter so the male part of the cone seats with the female cone in the off/on adapter and then tighten snugly using 2 wrenches to tighten run the jet .

If you encounter leaking ,shut down the jet (intensifier ) then tighten again . (The idea is to tighten very slowly until the leak stops) You may have to to this several times .DO NOT TIGHTEN TO TIGHT OR A RING WILL FORM AND YOU WILL HAVE TO REPEAT THIS PROCEDURE.

You may also encounter a leak in the weep hole behind the orifice this is due to a loose connection or a galled orifice or stem.

Verify that the stem is sealing to the orifice this will also cause the weep hole to leak when jetting

Look at the bottom of the stem and verify that there are no scratches ,also inspect the orifice. You may be able to lap out the scratches in a pinch .

Call Park industries if you need additional help

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.