Troubleshooting garnet flow restricted alarms. Step by step process to locate and correct garnet blockages

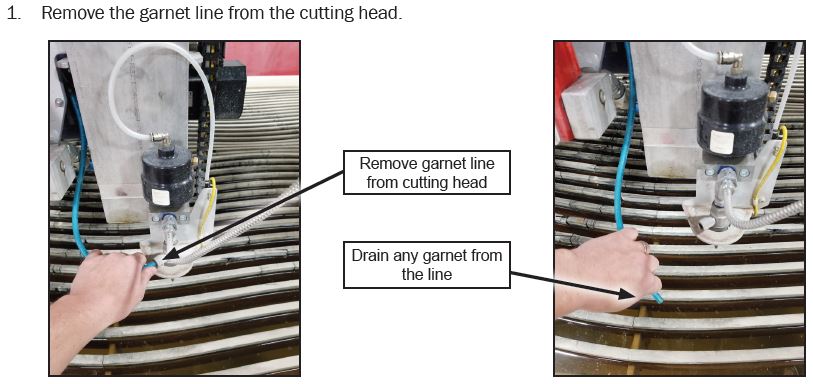

Position Cutting head to work on

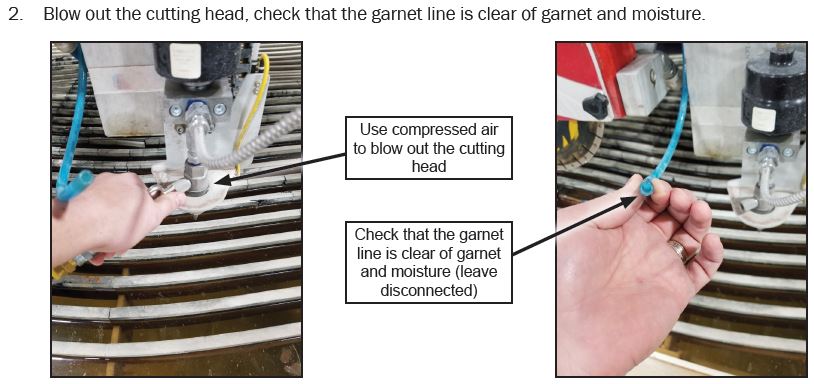

Using Compressed Air

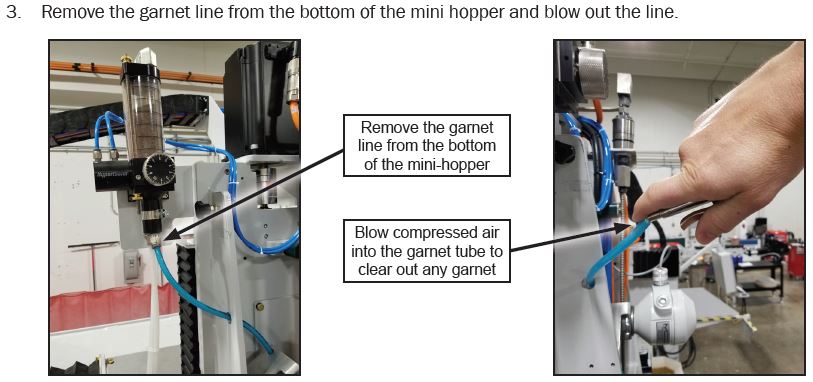

Clean Out Tubing

Reattach Blue Tubing

Connect the blue line to the bottom of the mini-hopper once the tubing cleared

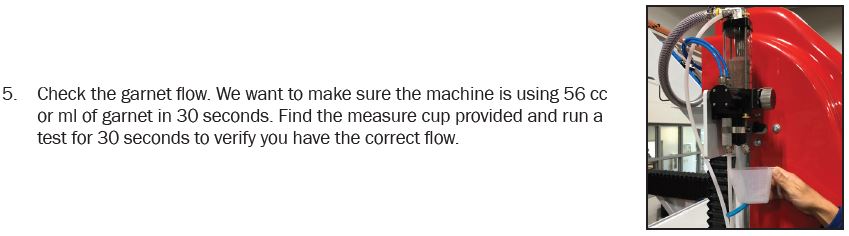

Check Garnet Flow

Correcting the Garnet flow amount

- If you don’t have the correct flow, either turn the round dial up if you need more garnet or down if you have too much. If you are unable to achieve the correct flow, do the mini-hopper maintenance found in the maintenance section of the operator manual or in the “Maintenance Help Screens”

Connect all hoses & replace any covers removed

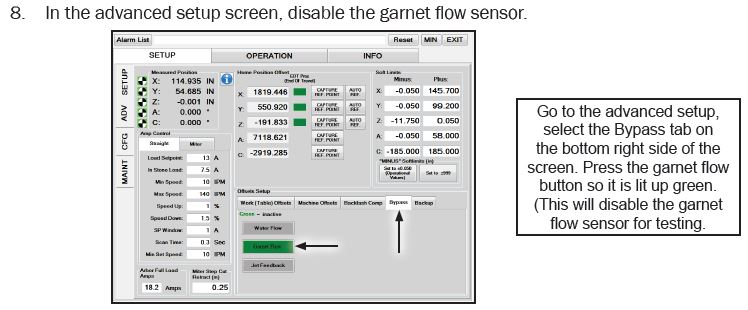

Disable Garnet

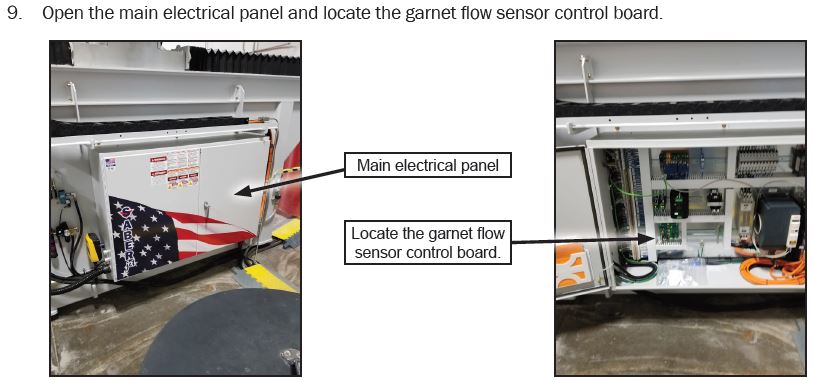

Locate the Garnet Control Board

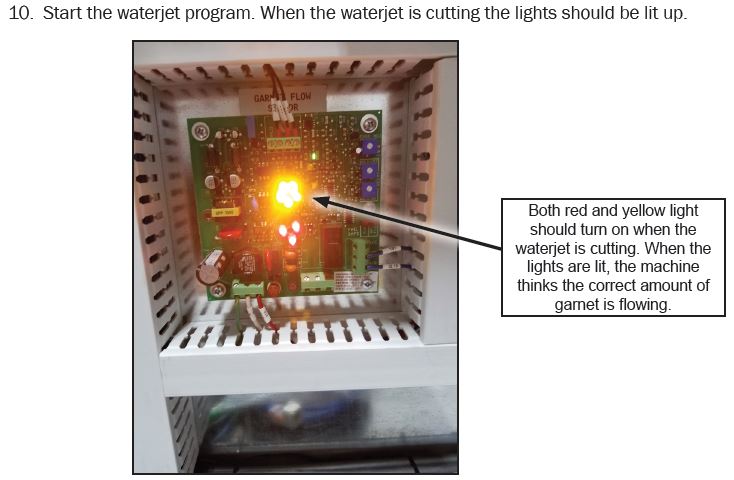

Enable the WaterJet

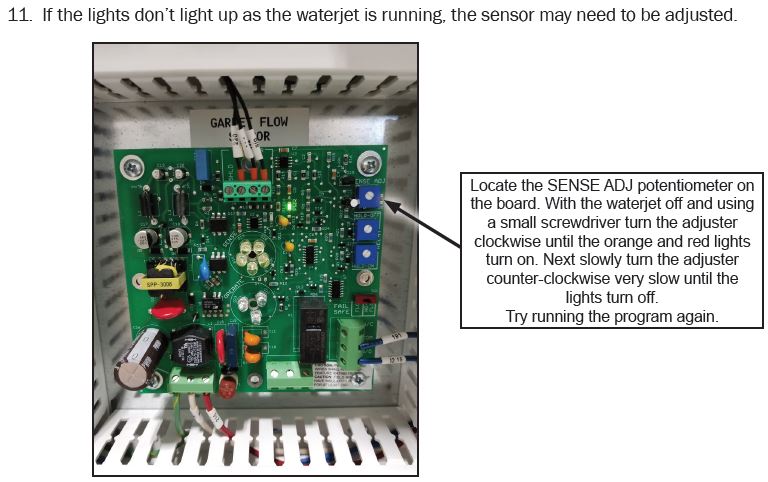

Making adjustments

Monitor the Control Board

Monitor the lights on the board while the machine runs a program. When the waterjet begins a cut,

the lights should turn on, when it finishes, they should shut off. (They should shut off between the cuts while the machine moves.) Run a complete job and monitor this, when finished, turn the garnet flow sensor back on by going into the advanced setup screen and pressing on the garnet flow button. When the button turns gray, the garnet flow sensor is active again.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.