How to maintenance and replace the Y-Strainer on Titan 3000 and 4000 series machines.

Scan to View on Mobile Device

There is a Printer Friendly PDF below for download.

Tools and supplies:

● Wrench set

● Adjustable wrench

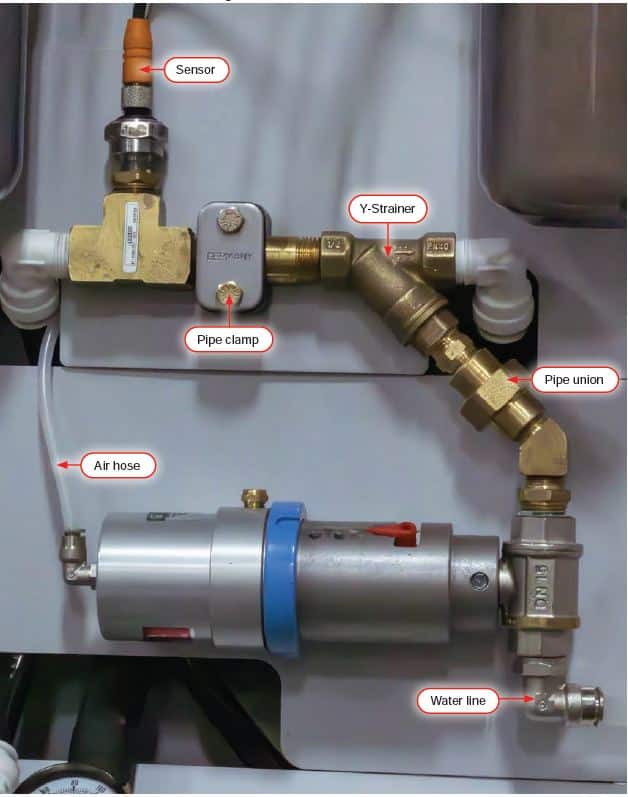

Reference IMage for both Procedures:

Maintenance:

Turn off air and water at the source and machine.

Remove the air hose and water line for the drain assembly.

Unscrew the drain assembly at the pipe union with an adjustable wrench.

Pull out and inspect the Y-Screen for buildup (replace or clean if necessary).

Note: check your shop’s water quality; monitoring buildup may be unnecessary.

Repeat steps 1-4 in reverse.

Turn the air and water on; check for leaks.

Replace:

Turn off water at the source and machine.

Disconnect the cord to the pressure sensor and the automatic valve’s air hose and water line.

Unscrew the 2 bolts from the pipe clamp, then remove the clamp.

Disconnect the Y-Strainer assembly at the brass nipple; the PVC elbows to the water in and out hoses; and the brass union to the blowout.

Note: secure the hoses to the panel before disconnecting them (use binder clips).

Remove the Y-Strainer from the assembly.

Apply pipe sealant or Teflon tape to all fittings and connect the new Y-Strainer to the assembly.

Repeat steps 1-5 in reverse.

Turn the air and water on; check for leaks.