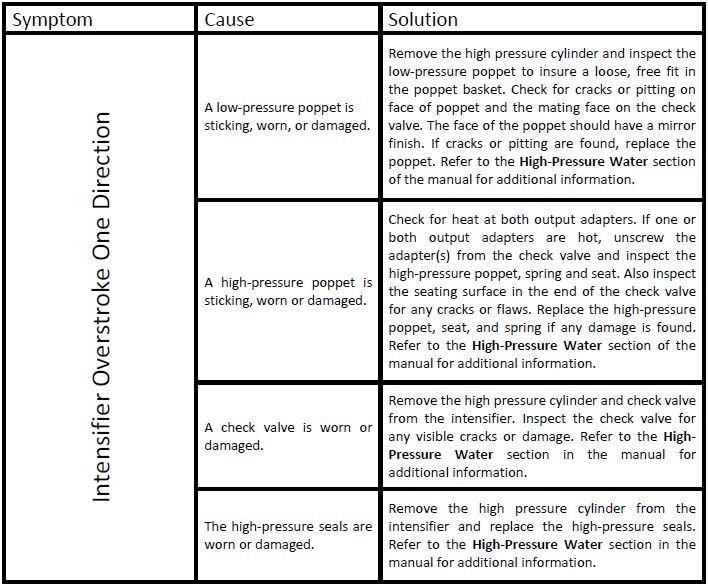

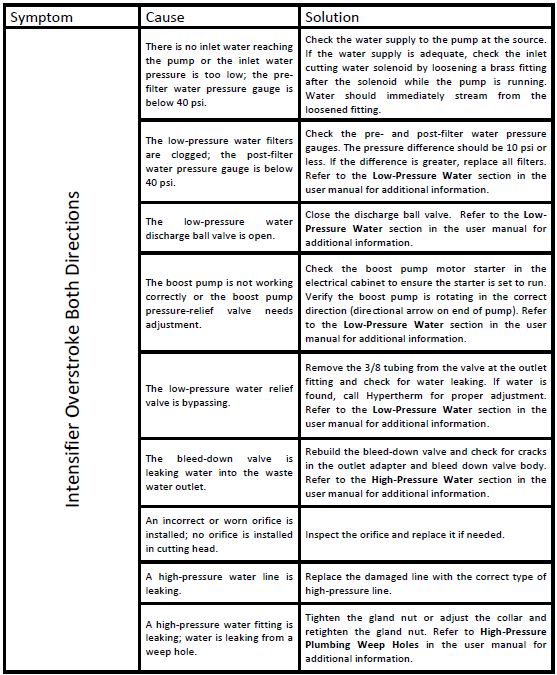

Intensifier overstroke happens when the piston in the intensifier strokes faster to one or both sides than the output flow of the waterjet pump can support. The maximum intensifier stroke rate is predetermined by the size of the hydraulic pump.

Instructions: Begin by shutting the cutting head off and bringing the waterjet pump to full pressure. Monitor the intensifier with the pump at full pressure and the cutting head closed.

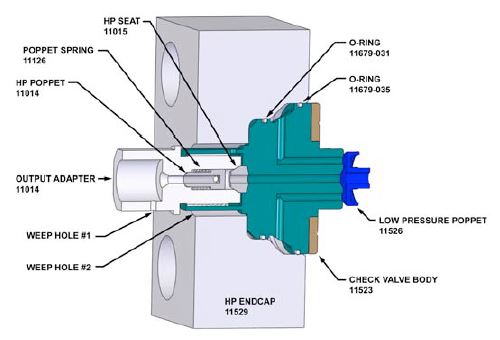

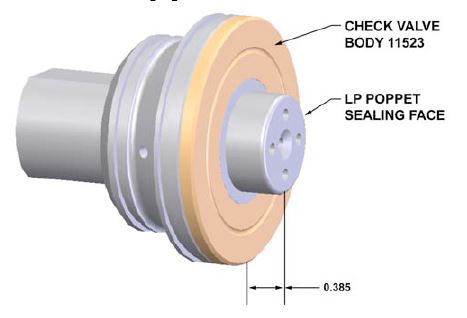

The intensifier should not stroke during this time. If the intensifier strokes, it is likely that there is an issue with a high-pressure poppet, a leak in the high-pressure plumbing (line or fitting), the bleed-down valve is leaking water from the waste water outlet, or the needle and seat in the cutting head are leaking. If the intensifier does not stroke with the cutting head closed, the most likely issue is a low-pressure poppet that is sticking, worn, or damaged. If the problem is not found, continue through the troubleshooting chart until the issue is found and corrected. For additional information or assistance with troubleshooting, please contact a Park Industries service technician.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.