This document illustrates the steps necessary to properly remove and cleanup a spindle on a Park Industries Fastback machine.

Shut off the air, water, and power to the machine. Follow your shop lockout, tagout procedures

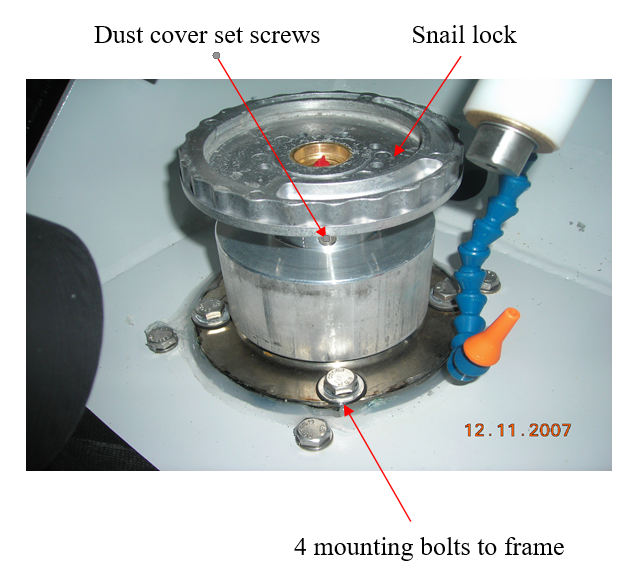

Remove snail lock adapter from spindle, and then the dust cover. Note, there are 2 set screws that hold the dust cover on

Remove the 4 mounting bolts as in the picture above and cut the silicone out also

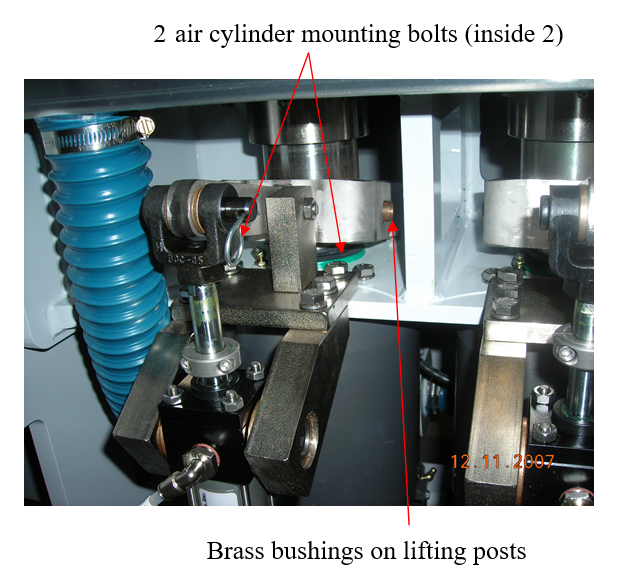

In the access door on the front of the machine, locate the air cylinder mounting bracket. Remove the 2 bolts that mount the bracket to the frame. Pull the air cylinder and lifting fork away from the spindle assembly. There are two brass bushings were the lifting fork attaches to the spindle, these are loose on the lifting posts and may fall off.

From the top of the machine, pull the whole spindle assembly up and out of the machine. (You will need to lift it up them rotate it 90 degrees so the lift posts will fit through the cutout.)

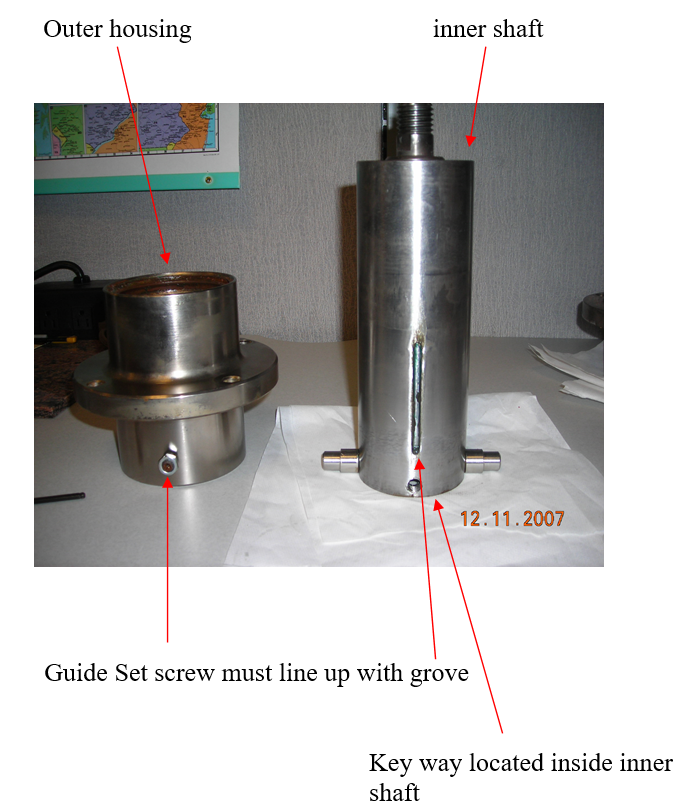

Separate the inner shaft from the outer housing

Loosen the guide set screw until the inner shaft slides out of the outer housing. Clean the inner shaft with emery cloth or fine sandpaper. Be careful to just remove the surface rust and/or build up. Clean until the inner shaft will slide freely in the outer housing. When re-tightening the guide set screw, be careful to line up with guide groove and do not over tighten or inner shaft will not slide freely

Re-assemble inner shaft into outer housing, and verify the inner shaft slides up & down freely Note: -Before putting spindle back into machine, make sure all the old silicone is is cleaned out

Re-assembly spindle assembly into the machine.

Note:

-When re-installing the spindle assembly, you must line up the key way on the bottom of the inner shaft with the key on the connecting collar located on top of the electric motor.

-When bolting the spindle down finger tighten all the bolts. Pull the spindle up and let it free fall down. Tight each bolt with a wrench 1/4 turn and check to see if the spindle free falls again. Repeat until the bolts are tight.

-Silicone around spindle when done and allow silicone to dry.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.