This procedure is an entire over view of the pump hydraulics. It includes several

procedures for setting and troubleshooting the hydraulic system.

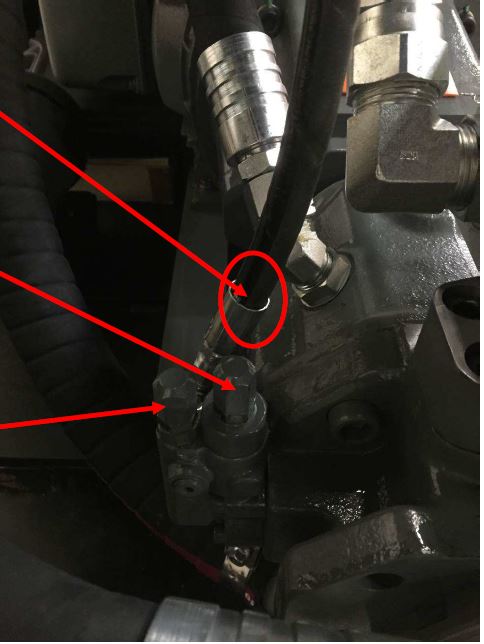

Component locations on the pump

This goes to the Hydraulic control valve. This allows a remote control of pressure between the low and high

pressure settings.

Compensator setting – this is the high pressure setting of the pump. This is the max pressure the Hydraulics will operate at. Factory set at 3150psi

Differential setting – this is the low pressure setting the pump run when in cooling mode. Factory set at 300psi.

Hydraulic Pump Relief Valve factor set @ 3700 PSI

How to measure hydraulic pressure.

1) You can use the analog gauge on the front of the Water Jet system.

2) A better choice would be a digital pressure gauge directly connected to the pump port. NoSHOK 0 to 5000psi gauge shown.

Setting only the differential pressure

1) Place the pump in “Cooling Mode”. Hydraulic pump ‘On’, Intensifier ‘OFF’

2) Loosen the jam nut.

3) Adjust the differential screw until the hydraulic pressure reads 300 psi.

4) Tighten the jam nut. Verify the pressure remains at 300 psi.

Setting only the compensator pressure

1) Place the water jet in high pressure mode. Make sure any user adjustments are all set to max pressure. Manual valves are screwed all the way in. If equipped with proportional control make sure it is set to 60k

2) Loosen jam nut

3) Adjust the compensator screw until the pressure reads 3150 psi

4) Tighten the jam nut and verify the pressure remains at 3150psi.

Setting the relief valve

1) Loosen the jam nuts on both

the relief valve and the compensator adjustment screws.

2) Screw the relief valve adjustment all the way in clockwise.

3) Place the water jet in high pressure mode. Use the setting compensator procedure on the previous page. Set the pressure to 3800psi.

4) Turn the relief valve counter clockwise until the pressure falls to 3700psi. Lock the Jam nut on the relief valve.

5) Reduce the compensator screw setting back down to 3150psi.

6) Tighten the jam nut and verify the pressure remains at 3150psi.

Trouble Shooting inability to build hydraulic pressure

The following procedure provides the best steps for setting the Hydraulic pump pressures manually. This procedure can also be used when you want to troubleshoot a Hydraulic pump problem. If the Hydraulic pump is unable to build pressure this procedure will allow you to manually spool up the pressure on the pump locally. This will eliminate the hose going to the manual pressure valve or proportional pressure control valve. If this procedure works to build pressure when normal operation does not, you will want to follow the hose and look at the control valve (manual pressure) or proportional control valve.

1) Remove the caps from the adjustment

ports.

2) Loosen the Jam nuts.

3) You will have a small amount of leaking Hydraulic oil when the caps are off.

4) Dial the Differential all the way clockwise. This will max out the setting and close off the port feeding the remote hose.

5) Now Dial the Compensator all the way out counter clockwise. This will set the high pressure to 0 psi.

6) Now place the pump in Cooling Mode to start the Hydraulic pump.

7) With the pump running, adjust the

Compensator screw until the pressure

reaches 3150psi. Hold the adjustment

screw while tightening the jam nut to

make sure it doesn’t change. This will

be your high pressure setting.

8) Back out the Differential screw.

The pressure will start to drop. Set

this to 300psi. This will be your low

pressure setting in cooling mode.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.