How to guide to replace the Titan 2X00 spindle servo motor.

Prep the machine for removal of motor

- Remove tool from spindle

- Park machine in the middle of the table

- Place Plywood or other protective barrier on the table

- Lower the spindle to lowest safe position

- Remove the safety pull cord

- Power down the machine and turn off air and water

- Complete a lockout / tagout for the machine

- Mark and remove the air lines for water deflector.

- Remove the hood off of cross travel covering spindle.

Removing Motor and Wiring

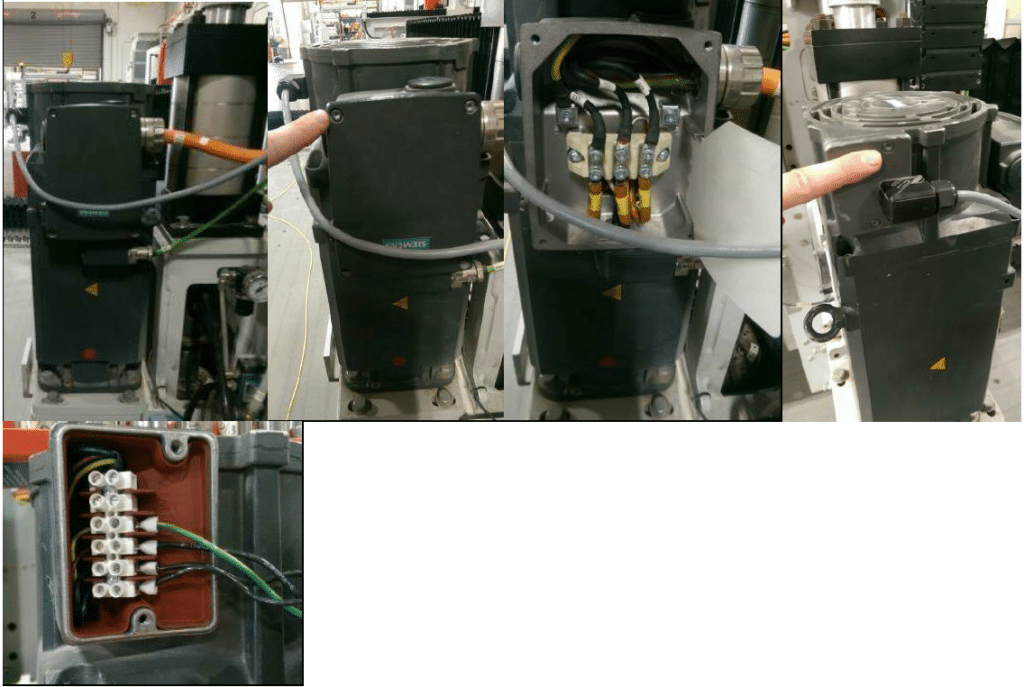

- Remove the cables from the motor. Requires a T20 for fan cord cover and 1/8” flat blade screwdriver for wire removal from terminals.

- Requires a T25 to remove screws for orange power cable cover and wire terminals. Then loosen cord restraint with adjustable pliers.

- Loosen the 4 screws in sloted holes with a ¾” box end wrench or socket and rachet and slide motor toward back of machine to loosen the belt tension.

- With a lifting aid hold light tension on the motor.

- Remove the four screws in the slots.

- Remove motor from rise and fall assembly.

- Remove the adapter plate from motor base using the ¾” box end wrench.

- Compare new motor setup to old motor setup.

- May need to move the fan on top to match old motor setup.

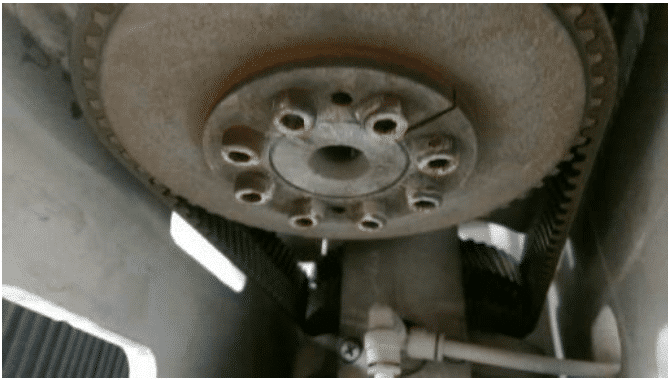

- On old motor remove the translock eight screws using a 5 MM allen wrench.

- Thread a couple screws into the threaded holes till tight.

- Now tap on the pulley toward the motor to pop the translock loose.

- Remove pulley and translock from motor shaft.

- Clean the shaft on the new motor.

- Place the pulley and translock onto shaft of motor making certain that the teeth are pointing on pulley in the correct orientation for the belt to engage in it.

- Torque screws to 12.5 ft lbs on translock making sure bottom is staying flush with end of motor shaft.

- Place motor assembly back onto the rise and fall in the correct orientation.

- Place into the adapter plate the 4 screws to secure motor assembly to the rise and fall loosely.

- Put belt on to the pulley.

- Place tensionset device into base plate and tension to proper setting the belt following proper procedure.

- Torque screws through slotted holes to 75 ft-lbs.

- Install the cables.

Machine Setup and Testing

- Install the hood.

- Install the air lines for water curtain.

- Install safety cord.

- Remove lockout/tagout.

- Power up machine.

- Test spindle in manual screen.

- Set spindle orientation following proper procedure.

- Test a couple tool changes.

- Return to production.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.