The Wizard water shot allows the operator to selectively add water to the Honing or Polishing process.

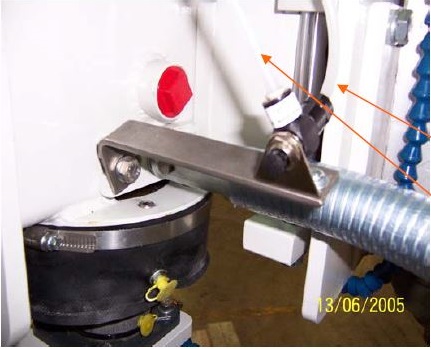

Remove the Front Handle mounting bolt using a 9/16 wrench. Place the L-shaped bracket on machine and reinstall the bolt.

Mount silver bracket ‘H’ to the L-shaped bracket. The bracket is to be mounted using the 10-32 slotted Head screws, washers, and lock washers included in the KIT.

Remove the 2 nuts and lock washer from the black push button included in the kit. Place the button into bracket ‘H’ facing as it looks in the picture. Attach it to the bracket with the first nut, then the lock washer and then the 2nd nut.

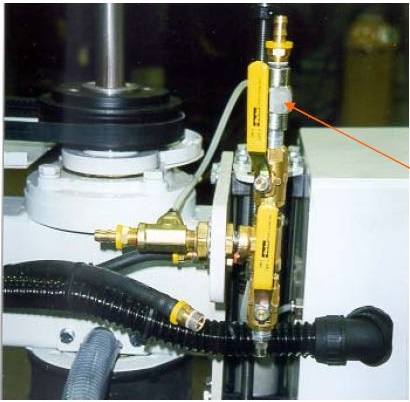

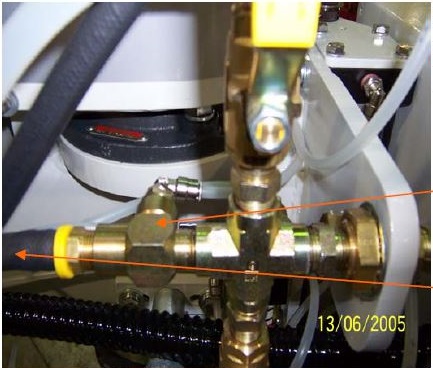

Add pipe tee fitting ‘J’ between spindle water feed line and upper ball valve. be sure to use pipe thread sealing compound on the threaded joints to prevent water leaks.

Add pipe tee fitting ‘K’ between white plate and the incoming water line. Be sure to use pipe thread sealing compound on the thread joint to prevent water leaks. Re-connect the water line.

Cut the hoses to the length needed and connect them to the push button. The hose from fitting ‘K’ goes to the back of the push button and the hose from fitting ‘J’ goes to the top fitting.

Attach 2 zip tie mounts to the white plate and run 2 water lines. One from fitting ‘K’ and one from fitting ‘J’. Attache the lines to the mounts with zip ties.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.