Majestic Kitchen and Bath is a large shop where reliability and meeting the schedule is everything. They went “all in” with Park Industries® and installed six TITAN®s in 2022. The CNC routers have delivered them the quality and dependability needed to continue to grow their business amidst a labor shortage.

Majestic Kitchen and Bath

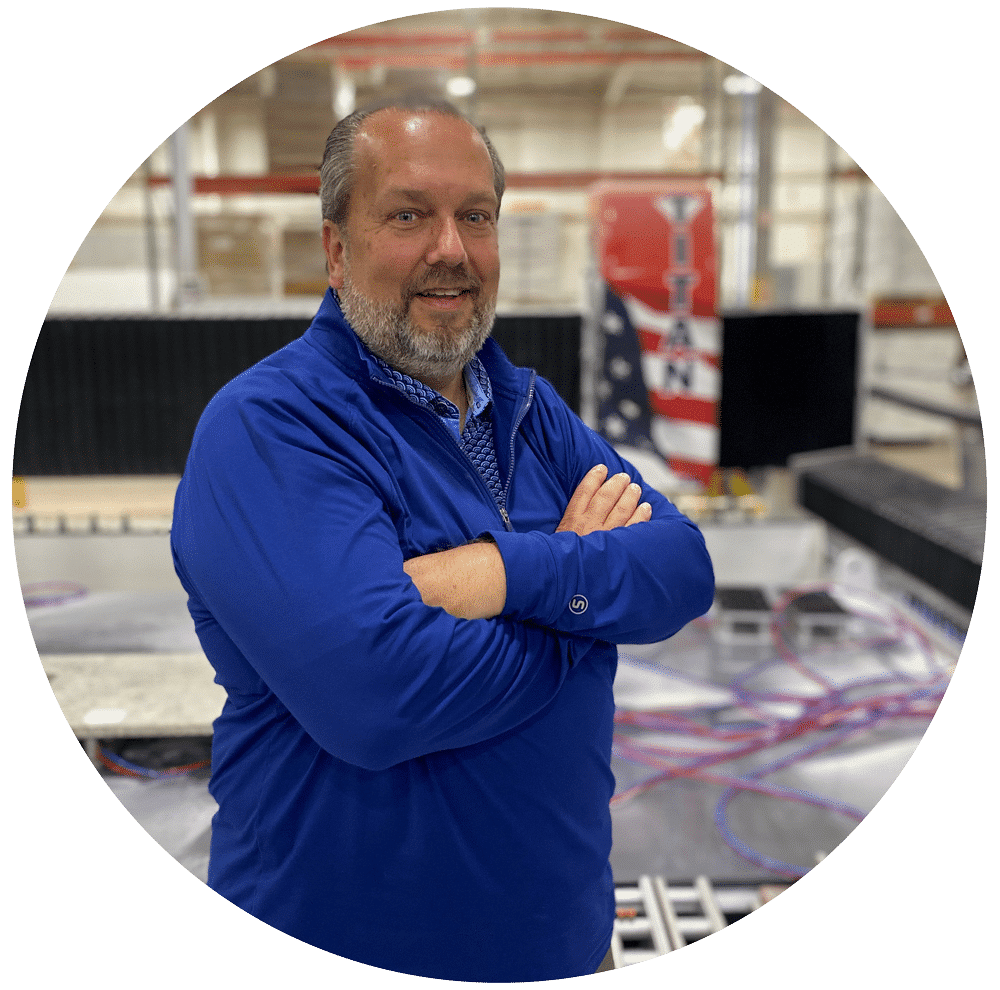

Scott Byers, President & CEO of Majestic Kitchen and Bath, chooses to work in stone fabrication because it is real. It is working with real people, real challenges everyday, and installing tangible final projects into our customers’ homes. Scott expands on this, “Often this is our customers’ biggest investment in their home and a part of their dream for their family. Thinking of it like that, we have the opportunity to make an impact on our customers’ lives.”

Majestic Kitchen & Bath, headquartered in Youngsville, NC, started out as a cultured marble shop in 1991. Scott Byers joined the business in 2017, and became President & CEO a couple years after that. There are 60 employees working in the shop, and it is not a growing number. Scott would like to use automation to grow the shop and to continue to deliver consistent quality to customers.

Read their story! Expand the sections below to learn more about their story and partnership with Park Industries®.

Labor Shortages

The industry is experiencing supply chain issues and labor issues. Majestic Kitchen & Bath is depending on automation for their long-term strategic focus. With a majority of customers in the building industry, the number one focus is to stay on schedule and to deliver that certainty – Majestic Kitchen & Bath’s customers depend on it. It is critical to their success. Scott and his company pride themselves on delivering the right product, right quality, on time the first time.

Time to Make a Change

Majestic Kitchen & Bath was an all hand polish shop. Scott wanted to find a more efficient approach to their fabrication process. Scott shared, “Hand polishing worked effectively for us for a while, but the labor difficulties we face in this industry forced us into looking for a more consistent, dependable solution.” They wanted to continue to deliver certainty to their customers, and so they looked to automation as a way to grow their business.

Why Park Industries®?

Majestic Kitchen and Bath had searched around before choosing their equipment manufacturer, but Park was their clear winner. Park’s long history of great machinery and great service spoke volumes. Majestic Kitchen and Bath cannot afford downtime with their meticulous schedule. They need to be up and running like clockwork. The fact that Park equipment is USA-made and the service team is capable of troubleshooting and sending parts within 24 hours made their decision easy.

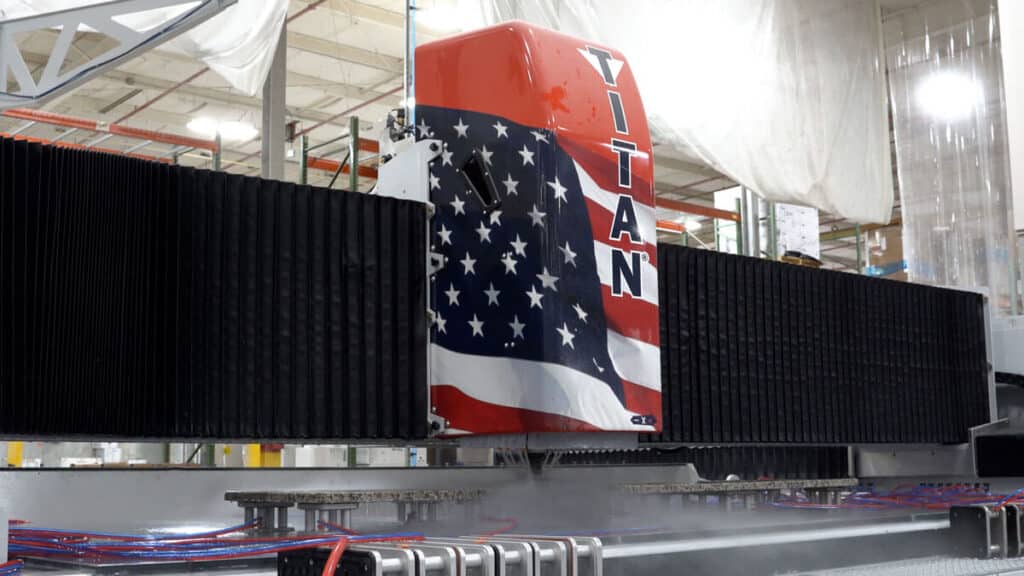

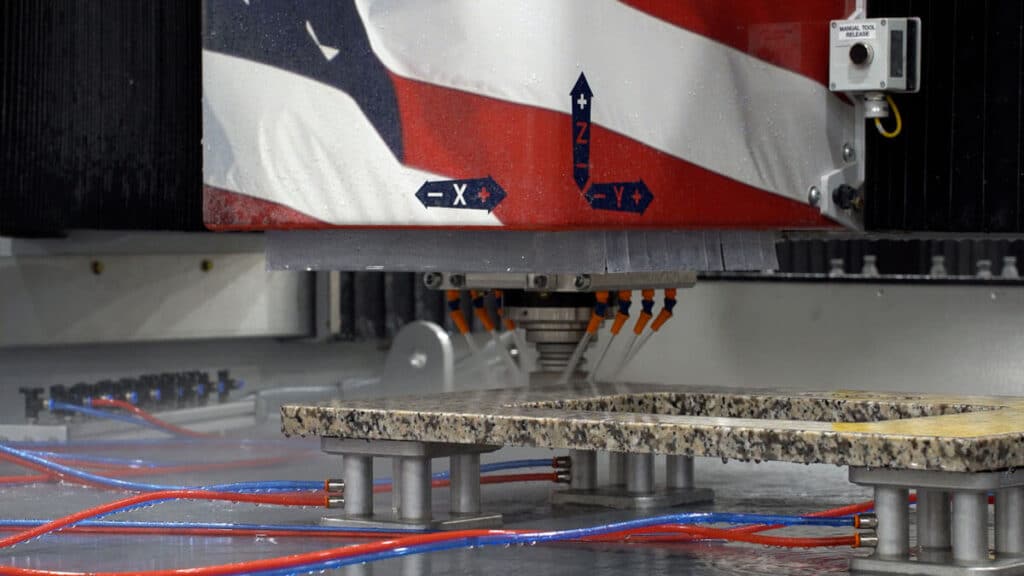

TITAN® Strong

Majestic Kitchen and Bath had initially invested in two TITAN®s, then ordered six more in 2022. Starting out with hand polishers and transitioning to an eight-TITAN® shop has been a culture change for Majestic Kitchen and Bath. Scott shares, “We are positioning ourselves for the future. We put all our chips on the table. Park is our partner in this.” They have been training polishers into CNC Operators and the TITAN®s will allow Majestic Kitchen and Bath to grow with less.

Scott is excited to have eight TITAN®s in full operation. He explains why they went all in on this machine, “We needed workhorse machines. The TITAN®s clearly fit that bill.” The install process was smooth sailing. Their sales representative, Matt Zink, took a look at their shop layout and assisted in configuring where the machines would capitalize on space and efficiency.

The Payoff

The TITAN®s are easy machines to run in a high turnover industry. It is a well-thought through machine. Scott is impressed with his TITAN®s and his experience with Park Industries®. He shares, “The TITAN®s pay for themselves, it is a consistent and high quality machine, and I’ll put the service that Park has up against any other manufacturers in the industry.”

“We can’t afford to be down, so we needed an excellent service team behind the machine to ensure minimum downtime. Park checked every box. It was an easy decision.” Park has the ability to help their team day or night, and has the option to service the machines remotely for convenience.

Results & Conclusion

Scott recommends others to review the history of Park as a company and talk to their customers if considering partnering with Park. Scott commends Park, “Park is a USA-based company with the parts, the talent, and the team to back quality machinery. After talking to a few customers, you’ll get a clear idea of the peace of mind that Park delivers.”

QUICK FACTS

LOCATION

Youngsville, NC, USA

TYPE OF FABRICATION

Countertop

NUMBER OF EMPLOYEES

60 in Fabrication Shop

PARK EQUIPMENT

TITAN® CNC Router x 8

PARK PARTNERSHIP

Began in 2004 with two Wizards