Priding themselves on customer service, high quality work, and a great company culture – Old World Tile & Granite has become a top fabricator in Arizona. A Park Industries® customer of nearly 20 years, their all-Park shop can produce 4,000+ sq. ft. in a week with a diverse lineup of machinery.

Old World Tile & Granite

Old World Tile & Granite opened its doors in 1979, started by Mike Kern, and has been family-owned ever since. In 2016, Philip joined his father in the family business, helping lead the charge to revolutionize their fabrication process.

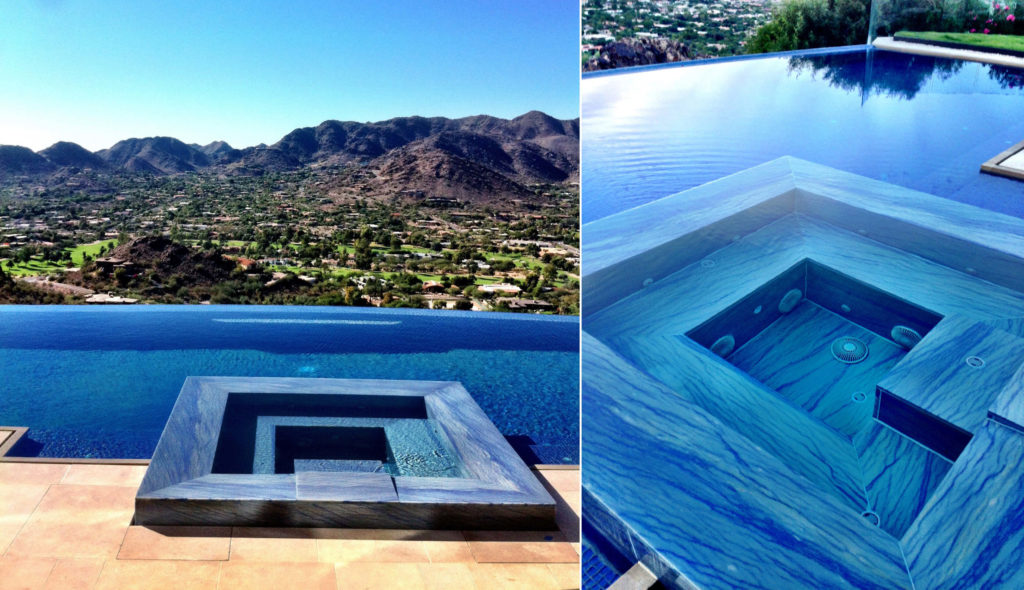

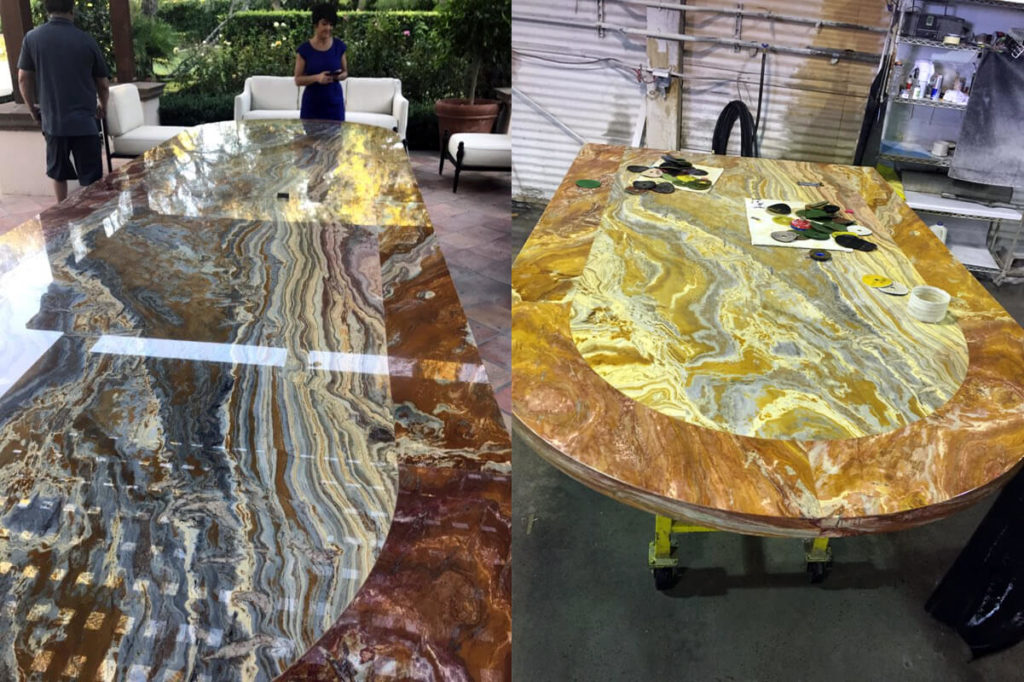

Excelling in custom projects, Old World does much more stone work than just countertops. They also offer flooring and walls.

Read their story! Expand the sections below to learn more about Old World’s story and their partnership with Park Industries®.

Intersection of Art & Science

The New Guy

After earning a Mathematics degree, Philip Kern needed one year of career experience before being able to start his MBA. His dad’s business, Old World Tile & Granite, seemed like a logical, convenient place for this interim year. And it was during this first year that Philip discovered his passion for the craft of stone fabrication.

Starting out wasn’t always smooth sailing. Because his dad owned the business, people often assumed that Philip was familiar with the stone industry – he wasn’t. Moreover, the differences between work life and family life stood out in stark contrast to one another as Philip worked to navigate these new waters.

The Family Business

Mike Kern, Philip’s father, started Old World Tile and Granite as a tile setter over forty years ago. As the company grew, people started asking for granite countertops, which seemed to be a natural fit with tile work.

Over the years, Old World Tile and Granite expanded their business. As the market changed, they found a niche with natural stone fabrication and grew into areas beyond just countertops. Today, Old World Tile and Granite works with a variety of materials, including some of the most challenging ones. There is not a stone, porcelain, or even metal on occasion that Old World does not fabricate with their machines.

A lot of their fabrication is miter work, architectural pieces, and high-end custom fabrication. The majority of their work is laminated and stacked lam edges, with only 5% of their work being non-laminated or mitered.

Two Sides of Caring for the Customer

The Wrong Way

In 1990, Old World purchased their first stone saw from an Italian company. When the saw needed service, to say it was a frustrating process would be a gross understatement. Philip recalls, “Just getting in contact with someone was like pulling teeth. Let alone, when we finally did, it took a month to get a part. We were down, that one bridge saw (100% of their production at the time) for a solid month.”

The Right Way

After experiencing that service nightmare, they knew they needed an American company they could depend on for their machinery needs. A company that could back up their quality machinery with dedicated service was paramount to them. Enter Park Industries®.

In 2001, Old World Tile & Granite purchased their first of many machines from Park Industries®, starting a 19 year and counting relationship.

When asked how their experience with Park has been different, Philip replies, “We really rely on the customer service that we receive. [With Park,] we can get ahold of someone immediately. Parts are overnighted. We’ve got someone who’s got our back.” He adds, “They treat their success the same way we treat ours, which is we’re not successful and we have not accomplished what we need to unless the end user is fully satisfied. And we cherish that.”

The Leap to Digital

After working at Old World Tile and Granite for about a year, and despite enjoying the work, Philip wanted to be able to apply his degree. At the time, Old World had not gone digital, but it was something that had been considered for years. When Philip agreed to lead Old World’s digital transition, they purchased their first CNC machine at Coverings just weeks later…a dual-table FUSION® CNC Sawjet.

To accelerate his digital learnings, Philip later attended Park’s Digital Stoneworking Expo™. He describes the event this way, “The first Digital Stone Expo™ that I went to was… I’ve got to say the best event I’ve been to in the industry. Period.”

An educational event for fabricators making the same digital journey as Philip, there was a lot of information to help him get started, and many other fabricators for him to network with.

Regarding the content, he adds, “It was purely educational. It felt like Park Industries® was only there to help your business change for the better, not to sell you a machine. I came out of [the DSE] with a whole new world to think about. We could never imagine going back to just bridge saws and hand fab.”

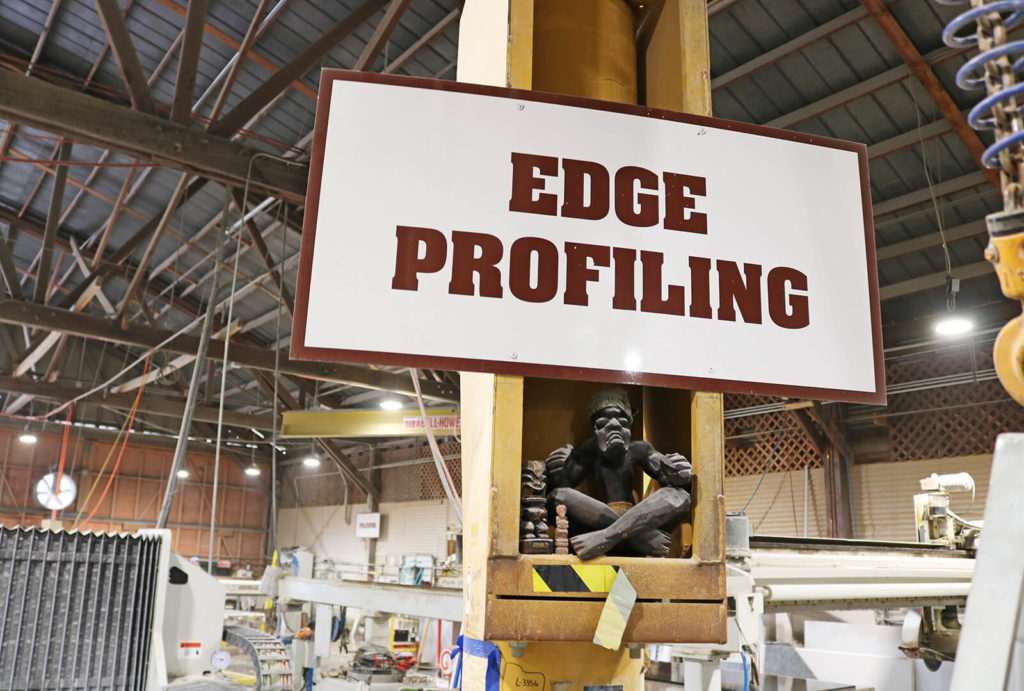

In spring of 2020, they added a FASTBACK® II Edge Polisher to handle their flat-edge polishing production.

Built to Last

All Brawn

Old World boasts an impressive machine line-up: a two-table FUSION®, a VELOCITY®, a FASTBACK® II, two PRO-EDGE® IV’s, two DESTINY XE’s, a Pathfinder®, and two YUKON® II’s.

Beyond the customer focus and service mindset, Philip keeps choosing Park for the durability of their equipment. He says it this way, “I think our machines speak for themselves. You do the preventative maintenance, which is very straightforward and easy, and these things last forever.” Which isn’t much of an overstatement. Old World’s first piece of Park equipment, a Jaguar saw, lasted for 18 years. What’s more, their DESTINY’s are each 14 yrs old and still running strong.

When planning machine purchases, this durability plays a critical role – both in terms of longevity and machine stamina. When they purchased their FUSION®, for example, they knew it could last fifteen years – they paid it off in about two. That other thirteen years? Pure profit.

Philip shares, “The dual bed FUSION®? Best decision we could’ve ever made. There’s zero lag time. When we’re in full swing, if there’s more than two minutes on that idle time, I go to our operators and I ask why.” Philip goes on to share that their Fusion will cut up to 25 slabs in an 8-hour shift. And that’s with the extra cuts for the laminate.

The Results

Because of their digital integration, process optimization, and efforts to maximize their fabrication capabilities, Old World is able to process 500 square feet per day with ease. And at least double that when they’re really busy.

Philip explains, “In a laminated market nonetheless, doing very high-end customer stuff alongside of the more high-end production stuff, our material yield has gone through the roof.” He attributes much of their capacity gains to the efficiency of their Park equipment. “20% less need of material. So, that’s just from being able to nest and waterjet. We’re not dealing with saw blade over-travels. We’re using every nook and cranny of that slab. And then tooling costs, that’s gone down 25%.”

There are other benefits as well. Old World has gone from needing 22 people to be at full capacity to needing 12. And they’ve used those gains to reinvest in their people – better wages, paying for more of their insurance, and higher percentage of profit sharing to name some examples.

Philip concludes by saying of Park Industries, “It’s that dedication to keeping us effective and efficient, that has built us up the way that we have, and that’s why we won’t look anywhere else.”

QUICK FACTS

LOCATION

Phoenix, Arizona, USA

TYPE OF FABRICATION

Stone Countertop & Exterior

WEEKLY PRODUCTION

2,000+ sq. ft. per week

NUMBER OF EMPLOYEES

12 in Fabrication Shop

PARK EQUIPMENT

FUSION® CNC Sawjet, DESTINY® XE CNC Router (x2), FASTBACK® II Edge Polisher, PRO-EDGE® IV Edge Polisher (x2), YUKON® II Bridge Saw, Pathfinder® Digital Photo Station

PARK PARTNERSHIP

Began in 2001 with a JAGUAR Bridge Saw (retired).