HYDRASPLIT®

Stone Splitter

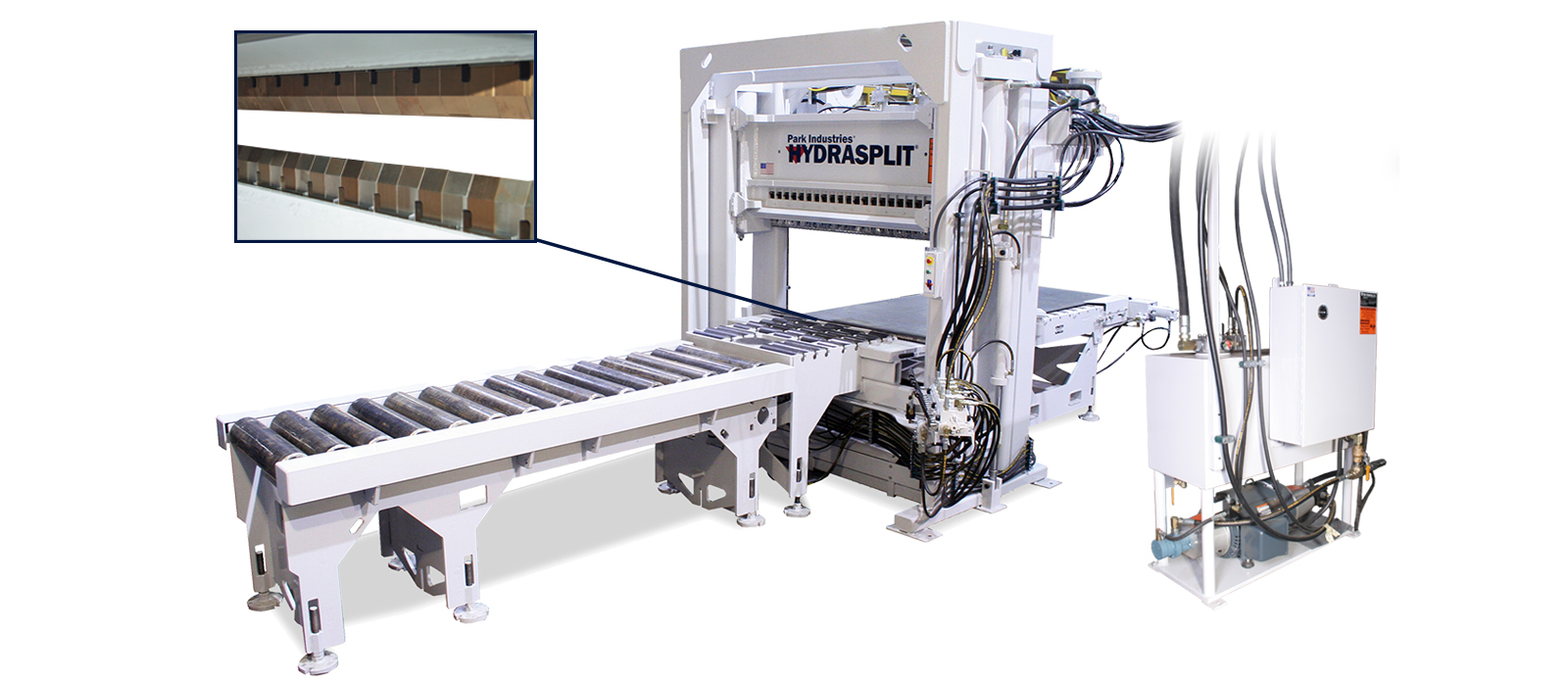

In “split” seconds, you’ll understand the meaning of power and precision. The HYDRASPLIT® Stone Splitter is a productivity powerhouse. Built and designed to maximize your stone yield performance, HYDRASPLIT® stationary stone splitting machines feature a wedged chisel equalization system to provide maximum contact with the stone surface for a cleaner arris line.

70+ YEARS

OF SPLITTERSUp to 300 Tons

of ForceSUPERIOR

SPLITS

Choose your Region

Please choose your region and fabrication type below.

Watch Videos

Key Features

- Power & Precision

Power and precision work together in every one of our HYDRASPLIT® stone splitting machines. We’ve engineered and built each machine to maximize your stone yield performance and profits, while minimizing labor costs and increasing uptime performance.

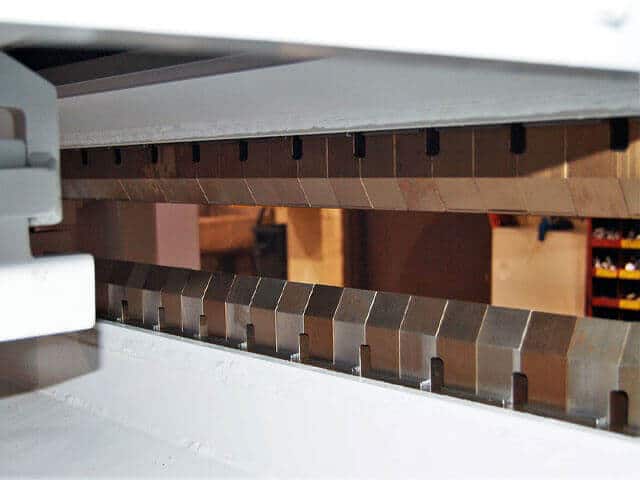

Our heat-treated and hardened high-carbon steel chisels produce superior splits every time. Our “dry wedge” chisel equalization system provides optimal chisel positioning for higher quality splits and less risk of chisels bending on hard stone. The narrow square chisels provide maximum contact with the stone surface for a cleaner arris line and minimum stone waste.

- Clean & Consistent

The secret to clean and consistent cuts is in Park’s advanced underhead splitting action. Unlike other machines, the HYDRASPLIT® makes the split from the bottom. This focuses all the cutting pressure on the stone, not the conveyor. The result is a crisp cut with clean arris lines—all without needing to raise the upper head.

- Efficient Material Handling

With a variety of material handling options, the HYDRASPLIT® Stone Splitter is customizable to fit with your specific shop needs. The material handling models vary in size and the styles range from a stone catch table to a heavy duty staggered feed gravity conveyor, and everything in between.

- Quick Splits

The automatic split cycle allows you to produce clean, quality splits 50% faster than other conventional overhead models. The automatic lower-and-lift system reduces the need to lift and reset the top head chisel with every split. Valuable operator time is saved.

- Smart Design

The HYDRASPLIT® Stone Splitter is built tough and engineered with a smart design. The solid steel box frame construction and open chisel-wedge rack assembly allows for easy maintenance and durability that will last for years. The bottom line is it is built to perform with maximum uptime and minimum downtime.

- Three Models of HYDRASPLIT®

- 36-16-150 Model (36″ chisel width, 16″ height, 150-tons of cutting force with 48″ throat width)

- 36-26-300 Model (36″ chisel width, 26″ height, 300-tons of cutting force with 48″ throat width)

- 60-26-300 Model (60″ chisel width, 26″ height, 300-tons of cutting force with 72″ throat width)

Specifications

| Select up to 3 models to compare key specs | HYDRASPLIT 60-26-300View Layout Drawing | |

|---|---|---|

| Cutting Force | 300 Tons | |

| Number of Chisels | 80 | |

| Cut Height Opening | 26" | |

| Chisel Width Area | 60" | |

| Throat Width Opening | 72" | |

| Infeed/Outfeed Conveyors | Yes (Optional) | |

| Power Unit | 30 HP Electric | |

| Footprint including clearance (L x W x H) | 29’7.75” x 15’.75” x 9’10.75” | |

| Weight | 20,000 lbs. (Doesn't Include Conveyors) |

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.

Out of all equipment I own, Park Splitters give me the most production with the least amount of issues.

Yes, I recommend this product.