Machine & Software Training

Flexible Training Options to Meet Your Stone fabrication Needs

Master Your Countertop or Architectural Machine.

Training Offerings

Two of your company’s greatest assets are your equipment and personnel. Park Industries Training Institute is comprised of the most talented and dedicated team of trainers who are focused on providing innovative, interactive training when and where you need it!

Thousands of fabricators have built their machine expertise with the assistance of Park Industries. Whether you attend training at Park Industries, at your location, or online, we have the training solution to meet your needs.

Class Types:

- CNC Machine Operations

- CNC Machine Programming

- Machine Maintenance

- Slabsmith Software

Class Formats:

- Online

- Onsite

- At Park Industries®

Request Machine Training

Explore Training Classes

Training At Park Industries®

Before your new stone countertop CNC machine arrives, you will attend training at our state-of-the-art training facility at our corporate headquarters in St. Cloud, MN.

Park-certified trainers provide hands-on experience tailored to address your needs and questions. You’ll leave training with the skills and knowledge to efficiently run your new machine from day one. Class sizes are kept small to give you more hands-on and face-to-face instructor time.

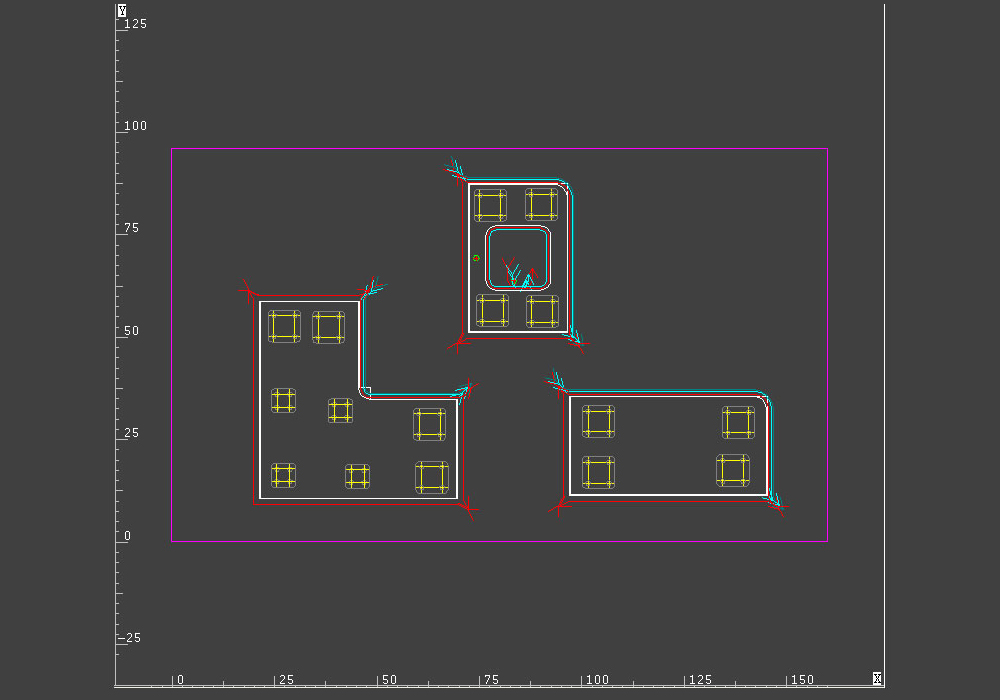

The hands-on philosophy of “learn by doing” is the most effective training available. Fabricators will learn CAD software, CNC programming, machine operations and preventive maintenance to properly maintain the equipment for increased longevity and optimal uptime.

Resources for Training at Park:

Online Training for stone countertop fabrication

Get the training you need without the travel expenses. Advance your skills from the convenience of your office. Online training is customizable and designed specifically to meet the needs of your personnel, equipment, and company.

We can help you with a quick programming refresher, full programming training, or an audit of your current programming process. Below are a few available courses:

Basic/Refresh Classes:

- SlabSmith Software

- TITAN Programming (basic tooling, styles, tool library, etc.)

- CNC Saw Programming (SABER, VOYAGER XP)

- CNC SawJet Programming (FUSION, SABERjet XP, JAVELIN)

Advanced Classes:

- Shower Plans

- Fluted Drain Boards

- Engraving

- Leather/Face Polishing

OnSite Training At Your Shop

A highly skilled trainer will train at your countertop fabrication shop and help your employees fully utilize the capability of your Park equipment. Onsite training is fully customizable. Similar to Online Training, we offer refresher programming training, full programming, an audit of your programming process, or full machine operation and maintenance training.

Onsite training allows us to focus on the one-on-one training that is most important to you. Onsite trainers can help you identify potential areas of opportunities for process improvements within your fabrication facility.

Invest in onsite training and save on travel expenses. Call Park today for the onsite training fee schedule.

Meet The Team

In order to maximize your return on your equipment, it is important that you have knowledgeable operators. No matter what material you’re processing, a Park Industries certified trainer will ensure that you are obtaining the full benefits your machine can offer. By partnering with Park’s well-trained staff, your organization will benefit from increased performance and maintain a competitive edge in your market. We are ready to help you.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.