With labor shortages remaining high as ever, stone fabricators are needing to push their limits of how much production they can get out of the door daily with as few of people as possible.

Fabricators are seeking ways to produce their backsplash and countertops more efficiently. There are two common bottlenecks amongst countertop fabricators. One common issue is that manually polishing backsplashes adds many extra hours of labor to a project. The other issue is that the CNC router has become the bottleneck in many fabrication shops and needs to be used more effectively. There are a couple ways to address the concerns of your shop, depending on the bottleneck occurring.

An automated solution, like a flat-edge polisher, will increase the overall efficiency of your shop whether the current bottleneck is labor, backsplash, or an overloaded CNC router. A flat-edge polisher can be used for backsplash, as well as vanities. And with a slab support system, its capable of running parts up to 96″ tall so you can run countertops and islands.

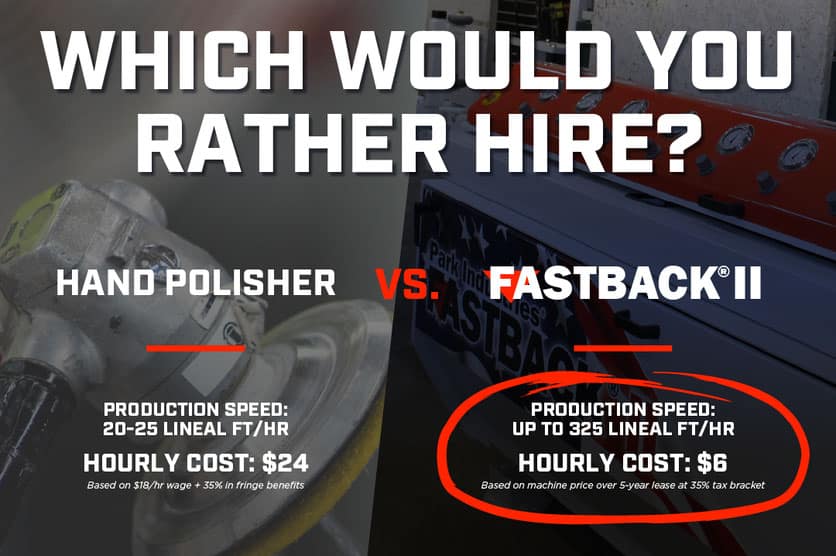

And the FASTBACK® II, for example, can polish these parts at speeds simply unmatched by other machines or hand polishers. Implementing a flat-edge polisher has a strong impact on a fabrication shop. The value of a machine like this pays for itself.

Joe Duszka, of Carolina Custom Surfaces, recently shared, “The labor savings with the FASTBACK® II is huge. The FASTBACK® II running for 1-2 hours will complete what it takes two qualified polishers to complete in a full day.”

A flat-edge polisher is capable of polishing up to 325 lineal feet per hour, while the average feet per hour that a hand polisher can finish is about 20-25 lineal feet. The automation of a flat-edge polishing machine is about 16 times more efficient than the manual labor of a hand polisher.

WATCH: How fast the FASTBACK® II can polish a pallet of backsplash?

The addition of a machine that will polish flat-eased edges is validated not only because of its efficiencies, but also because it helps with labor reduction and has the capability of bringing a fabricator’s costs down a substantially. Replacing a hand polishing position, or two, with a flat-edge polisher will not only cut down on hours per project, but also bring consistent predictability from project to project. An employee works at various speeds each day depending on a variety of factors.

A machine will consistently run projects through at a steady pace, which makes scheduling out projects hassle-free. In addition, a machine will not call in sick or take vacation days. A flat-edge polisher will bring dependability into your shop.

The load-and-go automation is fast and simple. Take the piece of stone off of your CNC saw and place it on the flat-edge polisher. In order to run linear tops through a flat-edge machine, there is no programming involved which will streamline the process even more. By utilizing an edge polisher, fabricators have the extra time on their CNC router to get more projects through it each day. It can all be done for pennies per lineal foot in tooling costs.

As fabricators are finding ways to become more profitable in the current economy, they need to be prepared to invest in efficiency. The flat-edge polisher solution will ease the stress of time constraints, labor pains, and a CNC router at its maximum capacity. An edge polisher can assist fabricators in freeing up time on their CNC router, and the labor hours that hand polishers put into each project. Utilizing the automation of a flat-edge polisher, like the FASTBACK® II, fabricators will thrive.

Roger Atherton from Counter Effects states, “I am extremely happy with my flat edge polisher and the quality it produces. We have replaced two labor positions with two hours of machine operation. This saves us 14 labor hours per day. A helluva payback. We are very happy with our investment.”