Are you on the verge of transitioning from hand polishing to an automated edge polishing solution? There are a variety of machines to choose from that are capable of creating anything from clean and smooth edges to 5-ogees.

Each machine will help your shop’s production in different ways. An edging machine may increase your productivity, decrease your labor costs, and assist in producing a smoother finish. Learn more about the edging machinery that Park has to offer below.

1) FASTBACK® II

The FASTBACK® II will edge, polish and chamfer backsplash as well as countertops in one single pass. This machine produces exceptional, quality edges at a rate up to 150 lineal feet per hour. The ability to track your machine’s metrics and success with the OPS Productivity feature is new for the FASTBACK® II. This proven workhorse of the stone countertop fabrication industry has been revamped to give you an even higher level of productivity.

2) VELOCITY®

The VELOCITY® Edge Polisher gives a single operator complete control for finishing high-quality edges on pieces up to 12 feet long. Park’s smartspindle technology and tool-stagger programming polishes top and bottom edges in one pass to save you material handling, manual labor, and valuable time.

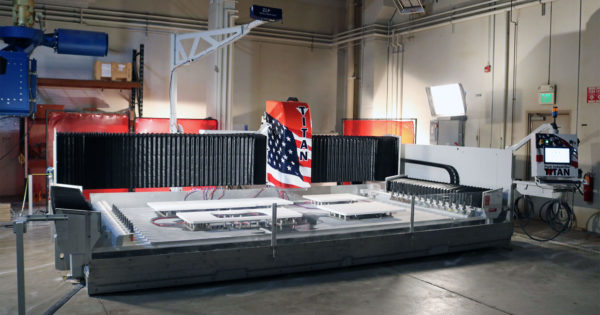

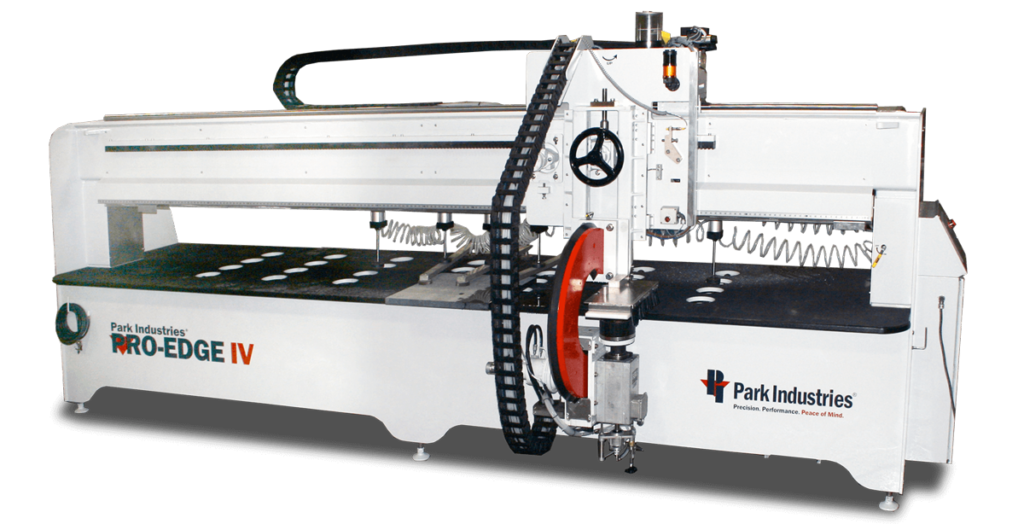

3) PRO-EDGE® IV

The PRO-EDGE® IV shapes and polishes a variety of convex edges. In addition, concave and ogee edges can be shaped and polished. The advanced control panel guides the operator through automatic steps and up to 70 programmable, repeatable edge profiles.

Analyze your shop and decide which machine solution will complete your shop’s production. Just as there are a variety of edge types, there are also a variety of edging machines. The addition of edging equipment will assist in decreasing manual labor hours and increase productivity. Understand the type of edging your shop fabricates and select the proper machine to fit your fabrication process.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.