There is plenty to consider when managing tooling for a CNC router: tool library, tool pocket location, the tool itself, and so on.

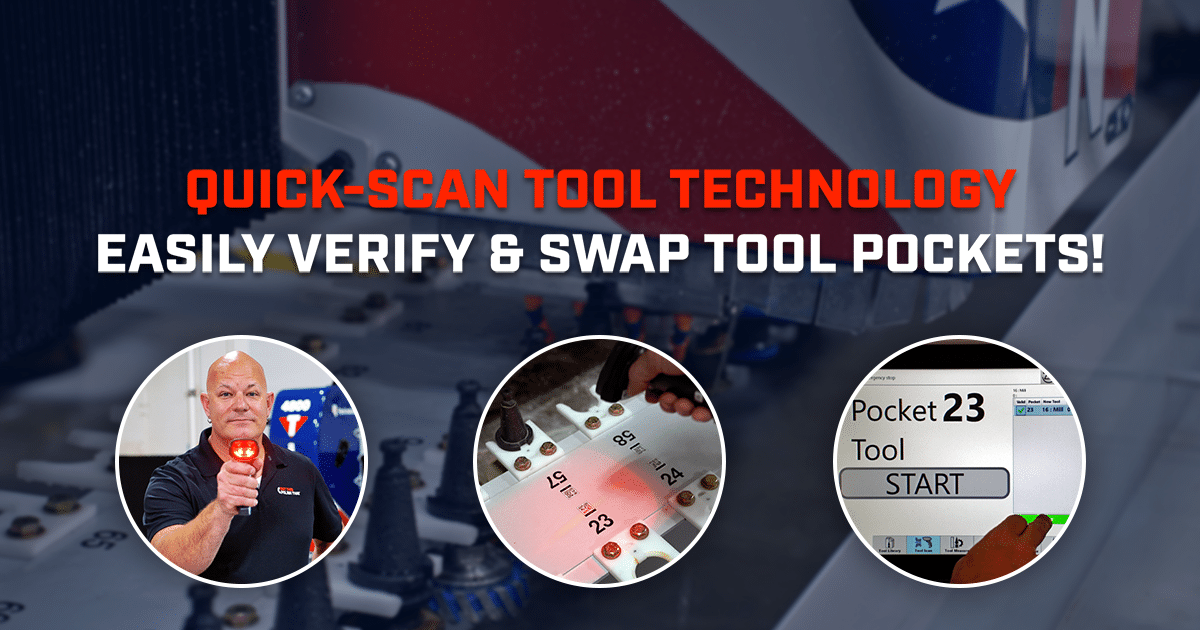

The TITAN 4000 CNC Router’s Quick-Scan Tool Technology is designed to solve the tool pocket location aspect of the equation for your CNC. In our latest video, see how to set up your tools with a scannable QR code sticker. This allows you to use the Quick-Scan feature to easily verify or swap tool pocket locations to save time and reduce errors.

Check Out the Quick-Scan Tool Technology on the TITAN CNC Router

When using this feature, it ensures the machine knows which tool is in which tool pocket. Even if tools are placed out of their normal order or pocket location, the machine will still pick them up correctly, avoiding potential damage to the stone. This feature is useful when swapping tool sets for offline measurement or when running multiple shifts, enabling one shift to verify tool placement from the other shift.

Only a TITAN shapes Greatness

Easy operation, fast production, the industry’s largest work area, and more have made the TITAN® 4000 Series the industry’s leading CNC Router. With its CNC automation, the TITAN delivers beautiful edges with 90% less labor. Plus, its built for maximum uptime with features like its exclusive ArmorDeck work table.

Curious about how the TITAN stands out? See the unmatched precision, reliability, and efficiency of the TITAN CNC Router from Park Industries®. Engineered with cutting-edge technology, the TITAN is designed for superior performance and high-volume production.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.