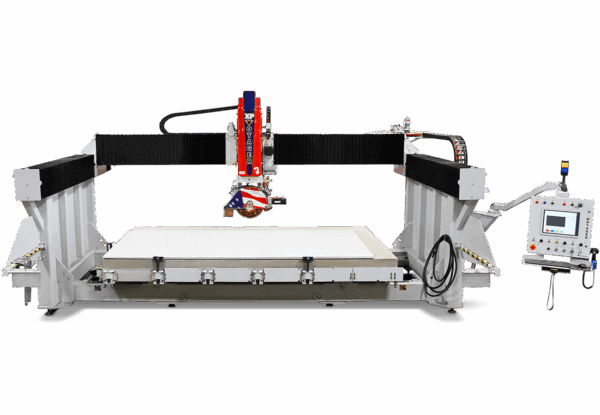

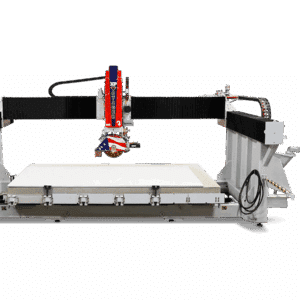

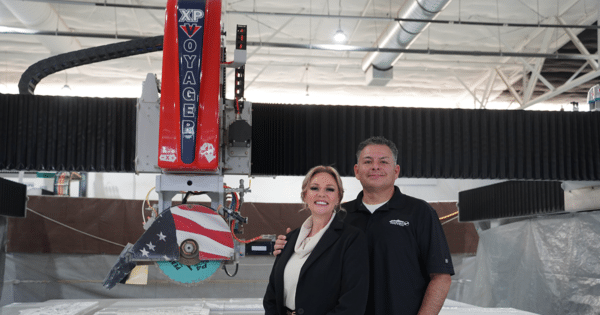

VOYAGER™ XP

5-Axis CNC Saw

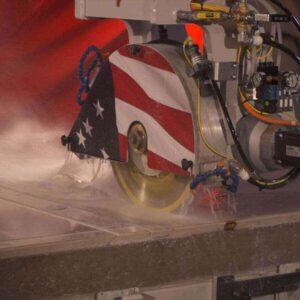

Retire your bridge saw and voyage into digital fabrication with the VOYAGER™ XP 5-Axis CNC Saw. Powered up with XP and a 27 hp motor, it cuts the hardest slabs such as porcelain, ultra-compact materials, and quartzite with ease. Its new TightCut™ feature nests parts closer together, increasing material yield by nearly 10% while reducing incremental routing time.

27 HP

MOTORTightCut™

Technology5-Axis

Sawing

Choose your Region

Please choose your region and fabrication type below.

Watch Videos

Key Features

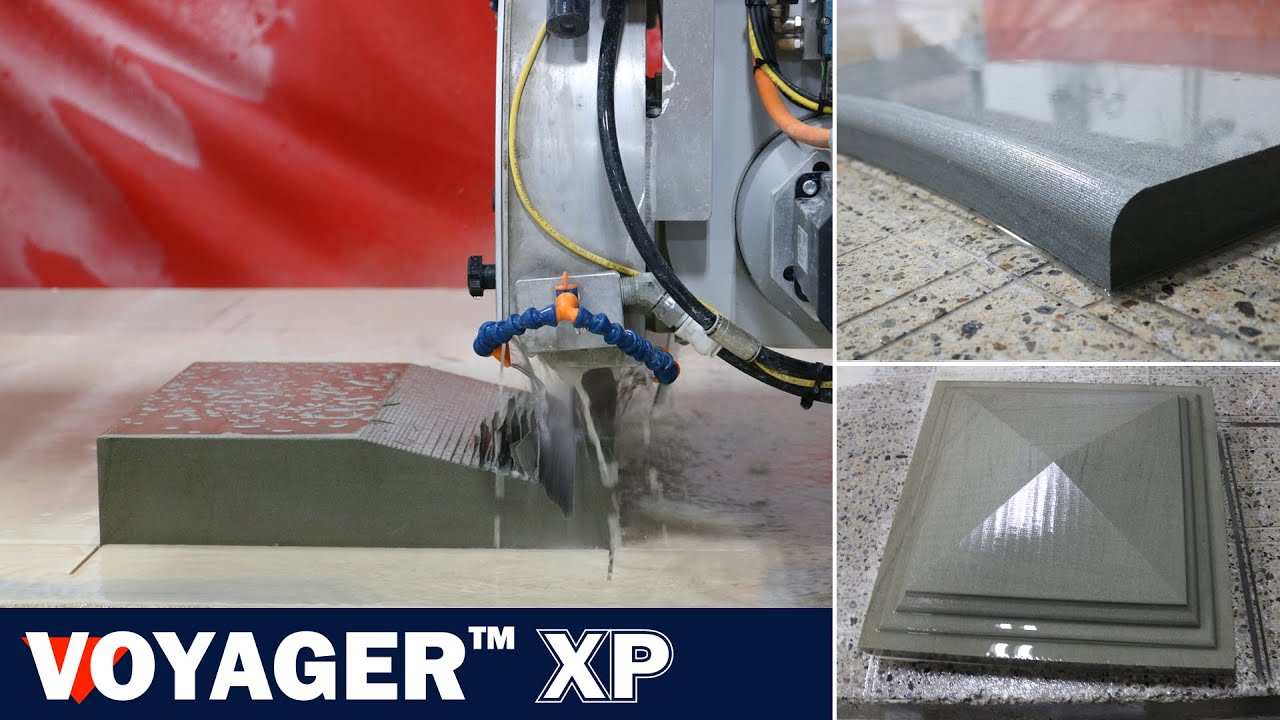

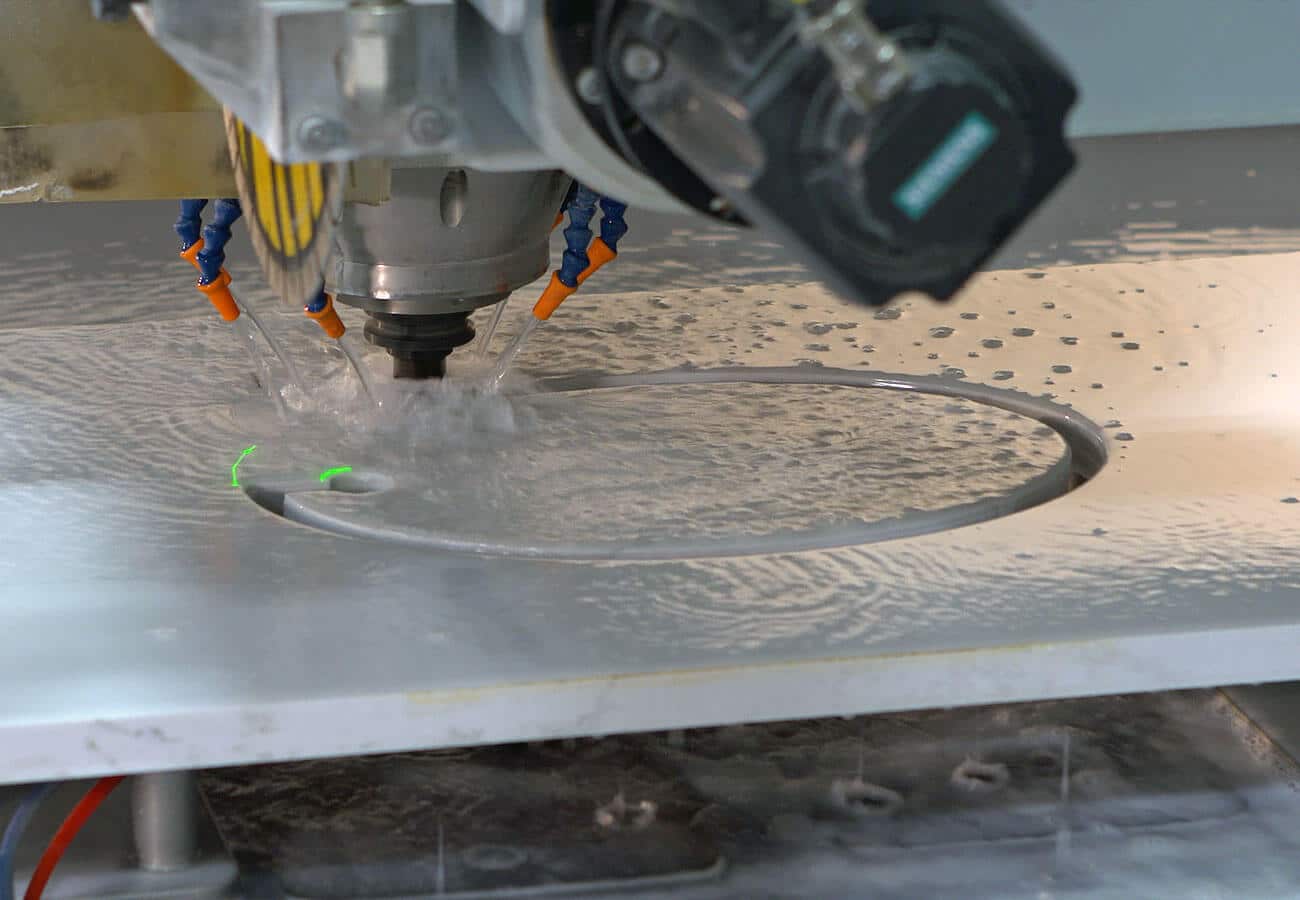

- 5-Axis Movements

The VOYAGER™ XP is a 5-axis CNC Saw, with the ability to move the X, Y, and Z linear axis and rotate the A and C axis; reducing overall program cycle times.

This design also allows for: continuous arc blade cutting, incremental routing, straight line profiling, faucet coring, 0-47° mitering and more, making it an extremely versatile machine.

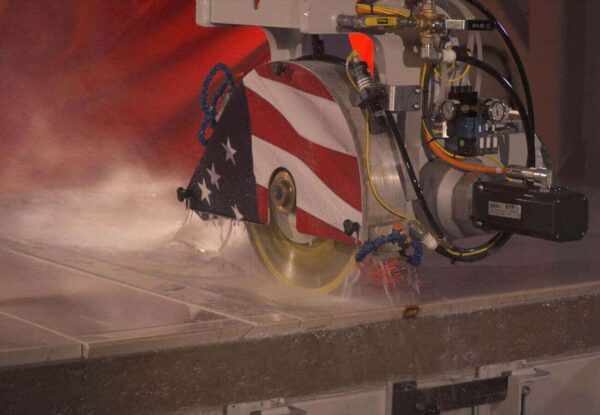

- Powered Up with XP

The spindle motor on the VOYAGER™ XP provides 27 hp to cut even the hardest of materials like quartzite at faster speeds. Built to run at a higher amperage for longer periods of time, the VOYAGER™ XP can push tools harder and increase the throughput of the saw.

With a standard VFD, the spindle can run from 1000 to 6000 rpm. The spindle arbor motor on the VOYAGER™ XP easily adapts to high-speed tooling evolvements or new materials, giving fabricators the flexibility to grow their business with the changes in the industry.

The VOYAGER™ XP runs with the world’s most popular operating system, Windows 10.

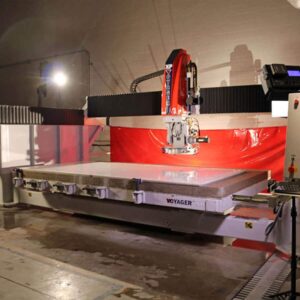

- Compact Design

The small footprint, single-pick, monoblock design of the VOYAGER™ XP is ideal. True unitized design with no bolt-on extensions resulting in extreme rigidity. The compact design requires minimal floor space and works well with low ceiling heights – only 10 feet tall.

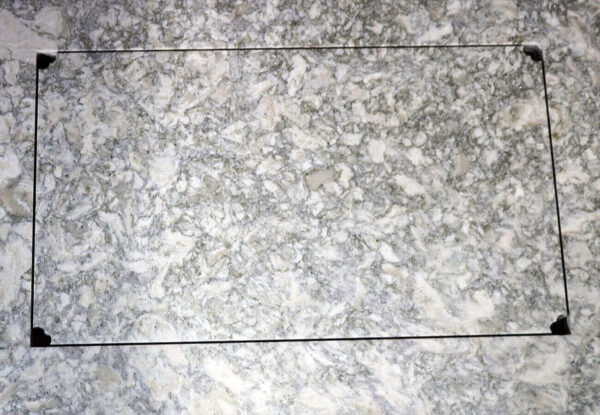

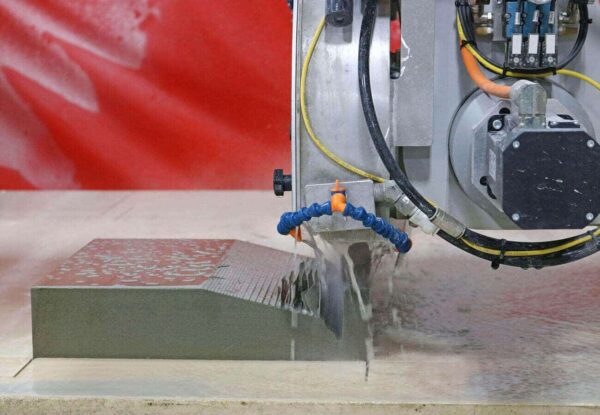

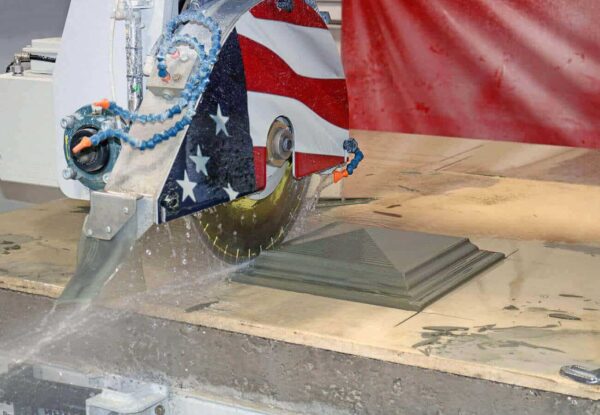

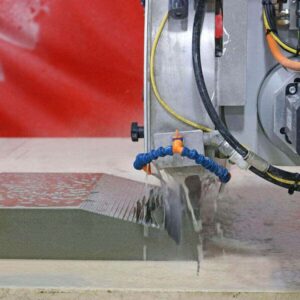

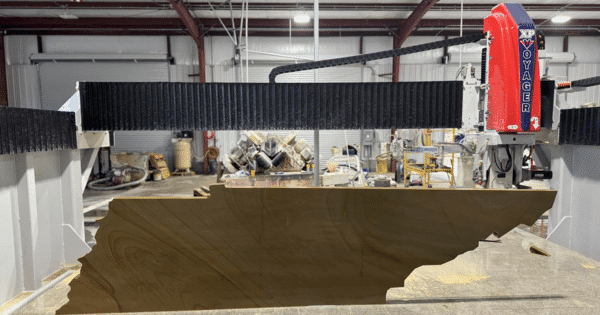

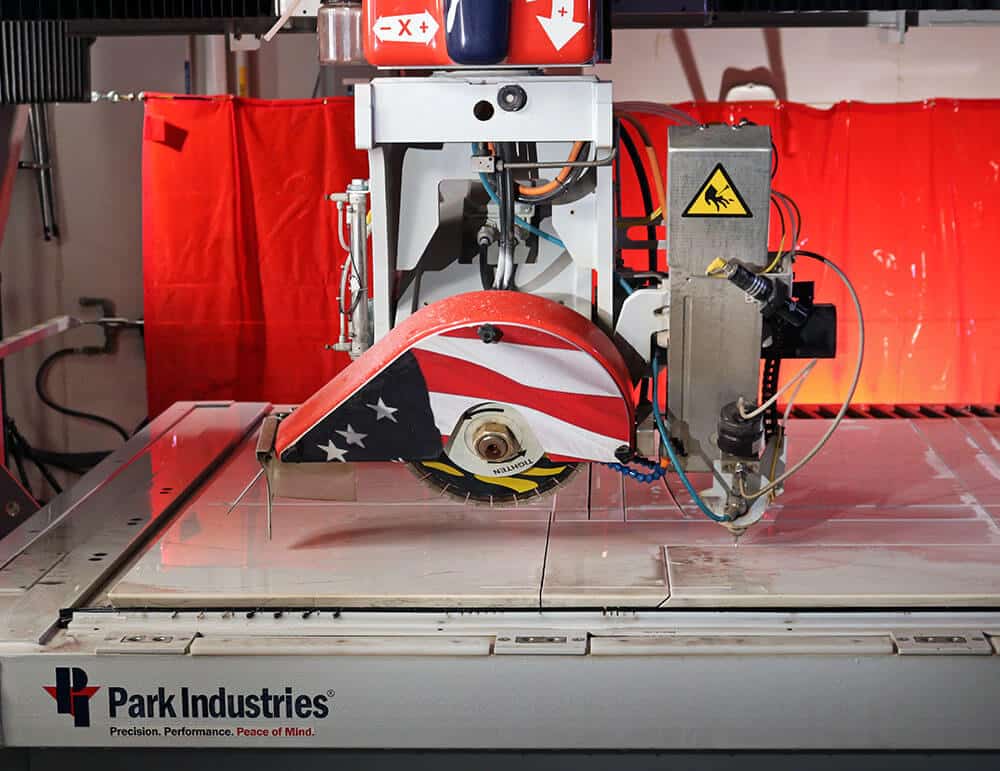

- TightCut™ Blade Plunge

Improving shop productivity and increasing slab utilization was the focus when Park Industries® integrated the TightCut™ blade plunging feature. Utilizing its powerful spindle motor, the VOYAGER™ XP plunge cuts into the table’s lightweight concrete surface.

Tight Nesting & Material Yield – With TightCut™, less than 1” of clearance between adjacent nested parts is needed versus the typical 4” on CNC saws without this capability; giving you the ability to improve slab utilization. Fit that extra piece of backsplash and gain up to 10% more yield of your materials.

Tight Inside Corners & Less Routing – Cut sharp 90 degree corners quicker with TightCut™ as its blade plunging feature minimizes the amount of routing time required to finish the material removal in the corner.

- Alphacam programming with exclusive Park EZ™ Buttons

Programming made FAST and SIMPLE! Park EZ™ Buttons, exclusive on Park Industries® CNC machinery, make common programming tasks EZ. Paired with Alphacam’s world-class CAD software, use over 40 built-in Park EZ™ buttons to eliminate tedious programming steps and increase your productivity.

With buttons like Auto Tool Path, Ultracompact Automation, and Parametric Shapes – you can save 60% or more of your programming time and clicks!

- Flexible, Operator Friendly Stone-Cutting

The VOYAGER’s orthogonal cutting mode allows operators to cut manually in any direction at any desired angle, with a laser line to guide these simple manual cuts without generating a program. Positioning of the machine is controlled by manual joysticks on the HMI or a wireless pendant.

Specifications

| Select up to 3 models to compare key specs | VOYAGER™ XPView Layout Drawing | |

|---|---|---|

| Arbor Motor | 27 hp | |

| Mitering | 0-47° | |

| Blade Size | 14" - 18" | |

| RPM's | 1,000-6,000 | |

| VFD | Yes | |

| 5-Axis Waterjet | NA | |

| TightCut Blade Plunging | Yes | |

| Tool Bit Attachment | Yes | |

| Cutting Modes | Full Auto (CNC), Manual | |

| Table / Tank Options | Hydraulic Tilt Table | |

| Cutting Surface Composition | Lightweight Concrete | |

| Camera Options | Overhead, SIDE-SHOT, or Pathfinder | |

| Max Slab Size (L x W) | 144" x 84" | |

| Max Cut Depth | 4.5" | |

| Monoblock Design | Yes | |

| Weight | 14,500 lbs. |

The VOYAGER XP fills all our needs and then some. We had been producing around 50 square feet a day before it, now we’re hitting 200 square feet a day with it. It’s been a gamechanger!

Yes, I recommend this product.

We bought the VOYAGER XP for a different reason than a lot of shops would. The main reason was for its ability to leather and hone slabs. It’s also our primary saw when we need to cut tricky materials or require miters with perfect accuracy.

Yes, I recommend this product.