From Pains

In 2010, Antonio Rojas started his company, ABC Custom Granite, as a one-man crew. He did everything – from sales, to templating, to fabrication and installation. His garage served as his shop, where he used a Makita hand-held saw to cut stone. He began putting out countertops all by himself, besides some occasional help from his wife and daughter who assisted with moving larger pieces of material.

Once he outgrew his garage, he bought his first major piece of equipment from an Italian manufacturer. Antonio describes this experience simply as, “A pain in the a**.” His stack of frustrations included the language barrier, tracking down service, and waiting 3+ weeks on parts. He recalls, “One time my Italian machine was down, sitting unused for 2 weeks waiting just for a little component. It put a ton of stress on me.”

He was ready to move on from that experience, so he called Park Industries® who he had heard great things about, especially regarding service. He purchased a PRO-EDGE® Edge Polisher, which worked well for them as a reliable, precise polisher – providing a ton of edge profile options. Immediately, he felt better about his machinery. He recalls, “I liked Park Industries® much better instantly. They returned my phone calls, helped me when I had problems, and got parts to me right away.”

Soon after, with ABC Custom Granite growing, he purchased a new building and started filling it with more machines from Park Industries®. The shop was still fabricating manually, when Antonio ran into a new pain – employees who were holding too much leverage over his production.

To Gains

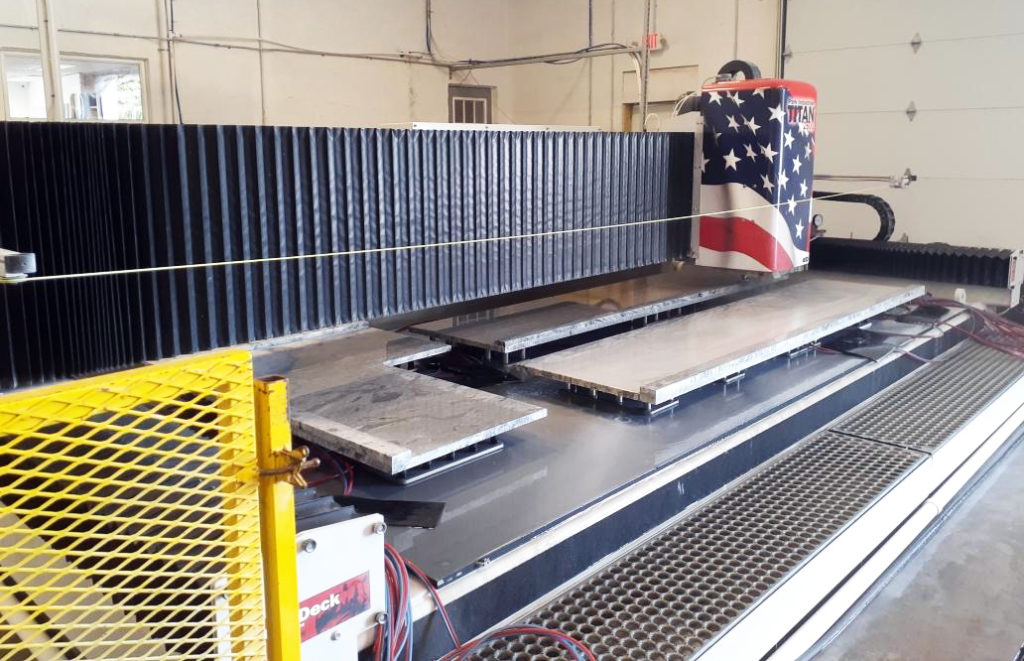

After a visit from his Park Industries® rep, Antonio was ready to explore digitizing his shop, so he attended a Digital Stoneworking Expo™ to understand the benefits of going digital. He learned so much from the Expo, he decided to go all in and purchased a new 10,000 sq ft building to make room for the right pieces of the digital process. Soon after he filled it with a SABERjet™ XP CNC Sawjet, TITAN® CNC Router, and FASTBACK® II Edge Polisher. The days of a Makita in the garage were long gone.

He describes the transition from manual to digital as another slight pain, having to learn fabrication in a new way, but one that was very worthwhile especially with Park Industries® being there for him to make sure the change went smoothly. He states he’d never go back to the old ways of manual fabrication.

Results of the Transition

Prior to their digital Park machinery, ABC Custom Granite produced about 3 jobs per day with 4 hand polishers. They now produce an average of 8 jobs per day with a lean fabrication crew consisting of a programmer/operator and just one polisher. Profitability for Antonio has gone way up, thanks to their production capabilities doubling and their labor costs dropping significantly. They are also now able to take on tough, complicated jobs with ease and the quality of their work has greatly increased. Lastly, being able to show off the high-tech, American Made machines have left a great impression on ABC Custom Granite’s clients. Antonio is proud to show off their machinery and shop.

SABERjet™ XP Delivers Reliability, Precision, & Speed

Carlos, Antonio’s best friend, handles all of the CNC programming and oversees the machine operations for ABC Custom Granite. When asked why they chose the SABERjet™ XP over other sawjets, Carlos responded, “We wanted the most reliable AND precise solution for blade and waterjet cutting. We also love mitered work so the mitering waterjet for inside corners played a huge factor.”

Since getting the SABERjet™ XP, Carlos has found that he “loves everything about the machine.” He describes how the accuracy of cuts and waterjet abilities are making life easier for their TITAN®. The hand polishers in the shop are also big fans, no longer spending unnecessary time cleaning up inside mitered edges, thanks to machine’s MiterJet feature.

Regarding the SABERjet™ XP’s 27 hp motor, he claims, “It doesn’t quit ever. We had some really hard quartzites and decided to run the machine at about 75% speed, which wasn’t necessary. The SABERjet™ XP is a workhorse and you can push it hard because it can handle it.”

A real eye opener for Carlos was when their biggest kitchen project came through the shop. He explains, “It was over 200 sq ft, but it was cut on the SABERjet™ XP and finished on the TITAN® in under one hour. From both machines to the truck…boom done.”

Each week Carlos is pushing the limits with machine, finding new ways to program and increase the efficiency of the saw. He enthusiastically shared a recent project they did, where he was able to make a 240” continuous arc with the blade. He recalls, “It was amazing to see. Unbelievable.”

Carlos concludes on the SABERjet™ XP, “The work we’ve been able to accomplish with that machine is amazing, everything is precise. The SABERjet™ XP just makes you look so good as an operator and programmer.”

FASTBACK® II for All Flat Edges

In regard to their FASTBACK® II, Carlos simply says, “We can rock with this machine. I love everything about the FASTBACK® II.” It polishes all of their flat edge production with exceptional accuracy and in an extremely efficient manner. Carlos states that they prefer to use a machine over manual polishers for this type of work.

ABC’s philosophy is to use it for any and all straight pieces. If a part has a sink, they’ll polish that on the TITAN®, but then run the outer edges on the FASTBACK® II. Carlos says they recently ran a 120” long x 36” tall part through it and was extremely pleased to see it turn out with a “perfect polish”.

A Cornerstone in The Journey

Reflecting on his journey in stone, Antonio is happy with how far he’s come. He credits Park Industries® for playing a major role in his journey, “Park was always there to help along the way. I feel like I chose the right company to partner with. I consider them as a part of my business…ABC Custom Granite wouldn’t be where we are today without Park Industries®.”

What stands out about Park Industries® for Carlos is, “Park Industries® will always tell us the truth…no matter what…sometimes that alone means more than anything else to us.”

Service is also huge for Carlos, “From the trainers, to installers to, 24/7 service – it’s always a great interaction. Whenever you talk to them, they stay with you as long as needed to answer all of your questions. I’ve had a very good experience with Park Industries®.”

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.